Production process flow of 18650 lithium battery pack cells.

The production process of lithium battery pack cells is divided into three major sections: electrode piece production, cell production, and battery assembly. What are the main production

Get Started

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Get Started

Small-scale Lithium Battery PACK production line plant

The main process flow of a lithium battery PACK production line includes the selection and matching of battery cells, the assembly of battery modules, the welding of cells, the integration

Get Started

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

Get Started

Production Process of Battery Modules and

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

Get Started

Battery Pack Manufacturing Process

Mar 15, 2025 · It consists of three major stages: electrode manufacturing, cell assembly, and cell finishing. Each step plays a crucial role in determining the

Get Started

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · Segments of the production line The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and

Get Started

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Get Started

Lithium-ion cell and battery production processes

May 3, 2018 · In contrast to module and pack assembly, the production of lithium-ion battery cells typically integrates various production technologies and draws on wide-ranging fields of

Get Started

Three battery pack production process diagram

battery ufacturing, cell assembly and cell in the lithium battery manufacturing process. (1) Integration of Cells into Packs The process of integrating individual battery cells into packs

Get Started

Facilities of a lithium-ion battery production plant

Mar 13, 2024 · 18.1 Introduction This Chapter describes the set-up of a battery production plant. The required manu-facturing environment (clean/dry rooms), media supply, utilities, and

Get Started

Key Points of the Manufacturing Process of

Dec 26, 2023 · The term "battery pack" generally refers to the assembly and manufacturing of a lithium-ion battery pack. It involves the integration of

Get Started

Empowering lithium-ion battery manufacturing with big

Dec 15, 2024 · The current research on manufacturing data for lithium-ion batteries is still limited, and there is an urgent need for production chains to utilize data to address existing pain points

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Interconnection of the battery cells

Get Started

Key Points of Lithium Battery PACK

Jun 27, 2024 · Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Get Started

Top 15 Lithium Battery Pack Manufacturers in

China has become the center of this lithium-ion battery industry, home to many of the world''s top lithium battery manufacturers. These companies are leading

Get Started

Three battery pack production process diagram

Learn about the three main steps of lithium-ion battery cell production: electrode manufacturing, cell assembly and cell finishing. See the operating principle, structure, design and Battery

Get Started

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Get Started

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Battery cell assembly is one of the key steps in the lithium battery module PACK production line. First, the battery cells are combined with

Get Started

Key Points of Lithium Battery PACK

Jun 4, 2024 · The battery pack typically refers to the combination of a battery, its processing, and assembly into lithium-ion battery packs. The key aspects

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Get Started

Battery Pack Manufacturing Process: Step-by-Step Guide

Dec 2, 2024 · The manufacturing of batteries is a meticulous process, involving several crucial stages that culminate in the creation of a functional and reliable power source. In this article,

Get Started

Lithium-ion Manufacturing and Risk Reduction

Mar 28, 2022 · The lithium-ion cell and battery manufacturing process requires stringent quality control. Improper design and manufacturing practices can

Get Started

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · The Battery Production specialist department is the point of contact for all questions relating to battery machinery and plant engineering. It researches technology and market

Get Started

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

Get Started

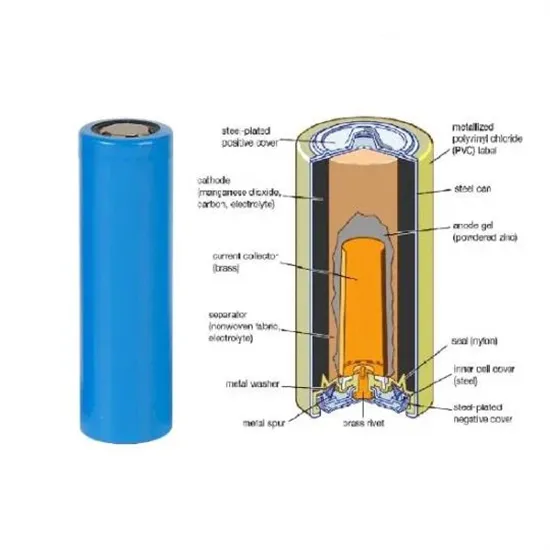

18650 battery manufacturing process and key

18650 battery manufacturing process and key points! 18650 refers to the external specifications of the battery, where 18 represents a diameter of 18mm, 65

Get Started

Key Points of Lithium Battery PACK Manufacturing Process

Jun 27, 2024 · Once the customized PACK lithium-ion battery requirements are confirmed, the production line will manufacture and process the PACK, followed by quality inspection and

Get Started

From Raw Materials to Finished Product: The

Nov 10, 2024 · In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Get Started

BATTERY CELL PRODUCTION IN EUROPE: STATUS QUO

Jul 1, 2024 · Battery cell production Europe nd battery market are also becoming noticeable in Europe. In Europe, ACC, AESC, CATL, LG Energy Solution, Northvolt, Samsung SDI and SK

Get Started

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Get Started

Facilities of a lithium-ion battery production plant

May 3, 2018 · This Chapter describes the set-up of a battery production plant. The required manufacturing environment (clean/dry rooms), media supply,

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and

Get Started

Current and future lithium-ion battery

Apr 23, 2021 · Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share

Get Started

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Get Started

6 FAQs about [Main points for lithium battery pack production]

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is the production process of lithium-ion battery cells?

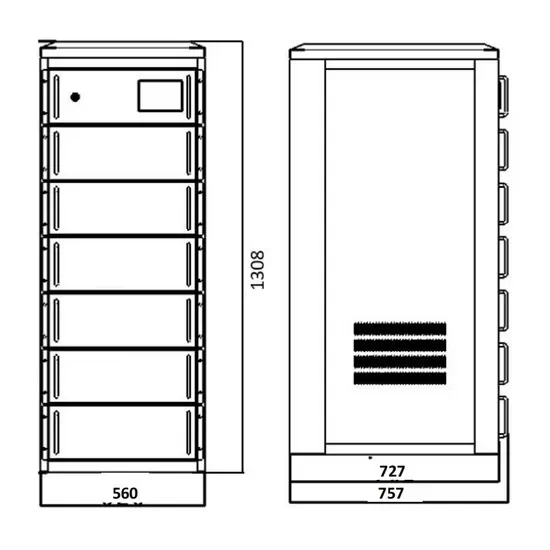

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is the battery pack manufacturing process?

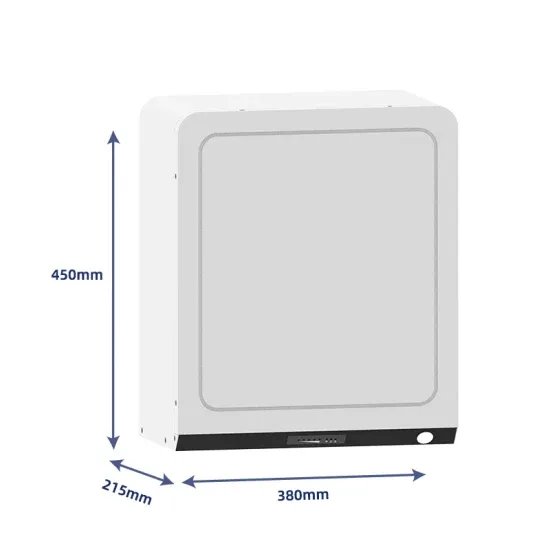

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

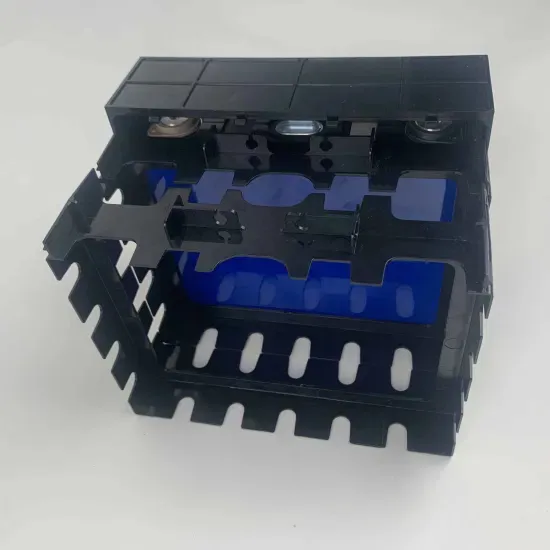

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

What are the parts of a battery production line?

Segments of the production line ● The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and safety requirements. ● From the point of view of factory layout, the assembly line can therefore be divided into cell-to-stack, stack-to-module and module-to-pack.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

Related Articles

-

Cylindrical lithium battery production battery pack

Cylindrical lithium battery production battery pack

-

Poor resistance of lithium battery pack

Poor resistance of lithium battery pack

-

China-Africa custom lithium battery pack

China-Africa custom lithium battery pack

-

Guatemala Lithium Battery Pack Supplier Company

Guatemala Lithium Battery Pack Supplier Company

-

South Africa purchases new 48v lithium battery pack

South Africa purchases new 48v lithium battery pack

-

Lithium battery pack 48v24a

Lithium battery pack 48v24a

-

Jamaica lithium battery pack OEM processing

Jamaica lithium battery pack OEM processing

-

Vilnius 26650 lithium battery pack

Vilnius 26650 lithium battery pack

-

Assembly of lithium titanate battery pack

Assembly of lithium titanate battery pack

-

What is the mc mark on the front of the lithium battery pack

What is the mc mark on the front of the lithium battery pack

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.