Battery Pack 12V40Ah

Mar 15, 2025 · Company Introduction:Established in 2007, Zhejiang GBS Energy Co., Ltd. is a national high-tech lithium battery manufacturer who specializes in developing and producing

Get Started

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Current manufacturing processes for LIBs LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature

Get Started

12V40ah LFP Battery Pack

Dec 13, 2023 · Company Introduction:Ningbo Shijie New Energy Technology Co. Ltd., founded in 2009, mainly focuses on the design, production and sale of high-performance lithium ion

Get Started

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Get Started

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Here in this perspective paper, we introduce state-of-the-art manufacturing technology and analyze the cost, throughput, and energy consumption based on the

Get Started

How Are Lithium Batteries Made? A

Sep 25, 2023 · Introduction With tech zooming ahead, lithium batteries are powering up just about everything. From our phones to our electric rides,

Get Started

12V 40ah Lithium Li Ion LiFePO4 Lithium Battery

Aug 6, 2025 · Standard battery pack from 12V-92V, 5AH-800AH, which can be used in electric vehicle, E-bike, UPS, energy storage system,

Get Started

The Manufacturing Process of Lithium Batteries

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in

Get Started

12V40ah LiFePO4 Battery Pack for Solar Street Lamp

Jul 22, 2025 · Company Introduction:Established in 2007, Zhejiang GBS Energy Co., Ltd. is a national high-tech lithium battery manufacturer who specializes in developing and producing

Get Started

How to Build A Battery Pack From 18650 Cells

Mar 30, 2022 · Building a lithium battery pack from 18650 cells can seem overwhelming, follow our how to guide for step by step instructions

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

High Power Lithium 12V40ah Battery Prices for Battery Pack

May 24, 2024 · High Power Lithium 12V40ah Battery Prices for Battery Pack UPS/Home Backup Power, Find Details and Price about UPS Power Supply Rechargeable Battery Pack from High

Get Started

Coslight 12V40ah Rechargeable Lithium Ion

Feb 26, 2025 · The lithium-ion batteries include three types, namely, square liquid batteries, polymer Li-ion battery and iron lithium batteries, produced by Harbin

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Get Started

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · Explore challenges and solutions in streamlining lithium-ion battery pack processes for efficient, customized, and automated production.

Get Started

Green Power Energy Storage Lithium Ion Battery

Apr 17, 2025 · Company Introduction:Established in 2007, Zhejiang GBS Energy Co., Ltd. is a national high-tech lithium battery manufacturer who specializes

Get Started

12V40ah UPS Battery with Lithium Battery Light Portable

Jul 3, 2024 · 12V40ah UPS Battery with Lithium Battery Light Portable Weight, Find Details and Price about Uninterruptible Power Supply Offline UPS from 12V40ah UPS Battery with Lithium

Get Started

BU-305: Building a Lithium-ion Pack

Oct 25, 2021 · Building a Li-ion battery pack begins by satisfying voltage and runtime requirements, and then taking loading, environmental, size and weight limitations into account.

Get Started

From Raw Materials to Finished Product: The

Nov 10, 2024 · In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Get Started

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The chair "Production Engineering of E-Mobility Components" (PEM) of RWTH Aachen University has been active in the field of lithium-ion battery production technology for

Get Started

Power Up Your Business with Advanced 12v40ah lifepo4 lithium battery

Experience efficiency and sustainability through innovative 12v40ah lifepo4 lithium battery technology. These batteries offer optimum energy storage while maintaining environment

Get Started

Lithium Ion Battery Manufacturing Process

Aug 17, 2025 · The production of lithium-ion batteries requires extensive procedures. This guide details lithium ion battery manufacturing process.

Get Started

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

Get Started

LiFePO4 Battery 12V40Ah

Feb 12, 2016 · OptimumNano always develop and produce 32650 cells to or assemble battery packs to satisfy the requirements of high performance and operational reliability of our customers.

Get Started

Deep Cycle Lithium Iron Phosphate Battery 12V40ah 50ah Battery Pack

Jul 4, 2024 · Deep Cycle Lithium Iron Phosphate Battery 12V40ah 50ah Battery Pack, Find Details and Price about Lithiun Ion Battery LiFePO4 Battery Pack from Deep Cycle Lithium

Get Started

How to make a 12 volt lithium-ion battery pack?

Nov 14, 2024 · Building a 12V lithium-ion battery pack can be a rewarding DIY project, providing you with a reliable power source for various applications. To

Get Started

Lithium Battery Manufacturing Process Step-by

Aug 4, 2025 · Ufine Battery lithium battery manufacturing process: electrode prep, cell assembly an''d testing. Custom solutions for high-performance batteries.

Get Started

Buy Rechargeable Lifepo4 Lfp Lithium Battery Pack 12v40ah Lithium

Buy low price Rechargeable Lifepo4 Lfp Lithium Battery Pack 12v40ah Lithium Ion Battery by Zhejiang GBS Energy Co., Ltd., a leading supplier from China. 902 similar products are also

Get Started

12V 40Ah Lithium Battery Packs

We use the latest lithium battery technologies to make the 12v rechargeable battery just ensure that you can get the highest quality and less or even no

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Started

Solar system 12V40AH lithium battery pack design example

Oct 14, 2022 · The model of Huizhong battery supported by Yonganhang Public Bicycle is: 12V10Ah,12V12Ah,12V17Ah,12V18Ah

Get Started

6 FAQs about [Produce 12v40ah battery pack using lithium battery]

What materials do I need to build a 12V lithium battery pack?

To build a 12V lithium battery pack, you will need the following materials: Wholesale lithium golf cart batteries with 10-year life? Check here. Lithium-Ion Cells: Commonly used cells include 18650 or LiFePO4 cells. Battery Management System (BMS): This device monitors and manages the charging and discharging of the battery.

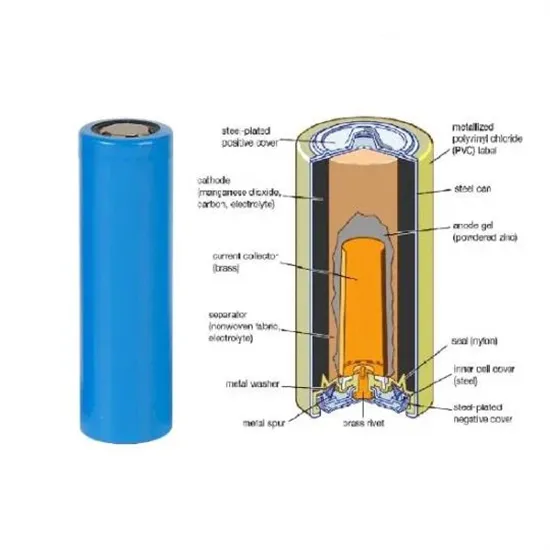

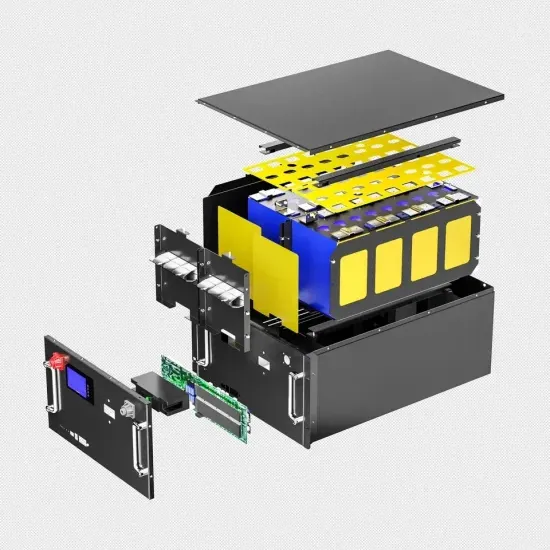

What is a lithium-ion battery pack?

Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and lightweight properties. In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack.

How do I assemble a 12V battery pack?

Assembling your battery pack involves several steps: Determine Configuration: For a 12V pack, connect cells in series. Typically, you will need four cells in series if using LiFePO4 (3.2V per cell) or three cells if using standard lithium-ion cells (3.7V per cell).

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the transferability of competencies from the production of lithium-ion battery cells is discussed. The publication “Battery Module and Pack Assembly Process” provides a comprehensive process overview for the production of battery modules and packs.

How do you build a Li-ion battery pack?

Building a Li-ion battery pack begins by satisfying voltage and runtime requirements, and then taking loading, environmental, size and weight limitations into account. Portable designs for consumer products want a slim profile and the choice is a prismatic or pouch cell.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

Related Articles

-

How much does it cost to produce a lithium battery pack

How much does it cost to produce a lithium battery pack

-

Use soldering iron to produce lithium battery pack

Use soldering iron to produce lithium battery pack

-

How much is the lithium battery pack in Afghanistan

How much is the lithium battery pack in Afghanistan

-

Lithium battery pack field changes

Lithium battery pack field changes

-

Kenya lithium battery battery pack

Kenya lithium battery battery pack

-

Ul lithium battery pack custom made

Ul lithium battery pack custom made

-

Colombia ups power lithium battery pack

Colombia ups power lithium battery pack

-

The higher the voltage of the lithium battery pack the safer it is

The higher the voltage of the lithium battery pack the safer it is

-

How much does a lithium battery pack factory cost

How much does a lithium battery pack factory cost

-

Lithium iron phosphate battery pack forced charging

Lithium iron phosphate battery pack forced charging

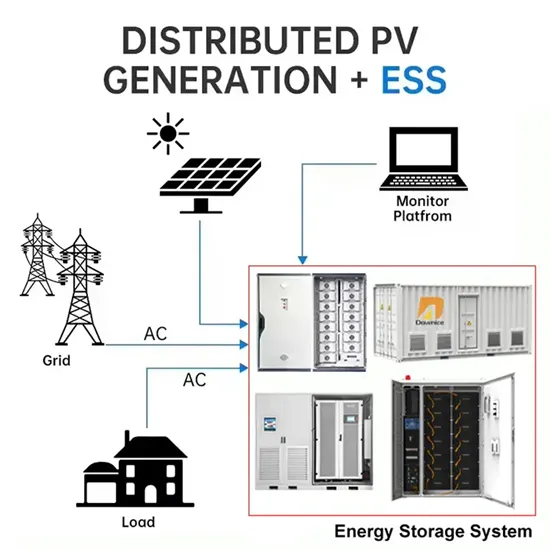

Commercial & Industrial Solar Storage Market Growth

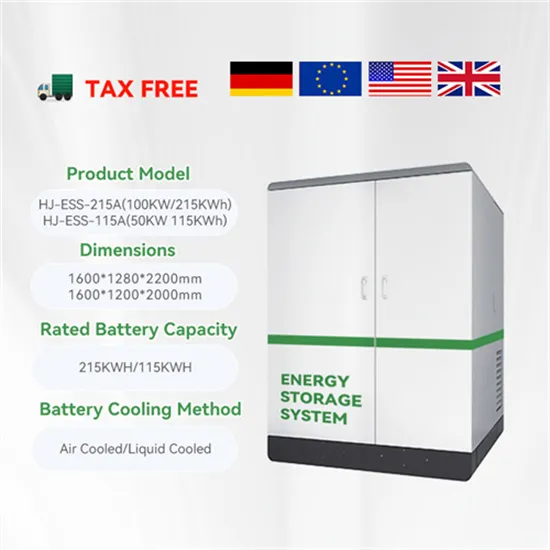

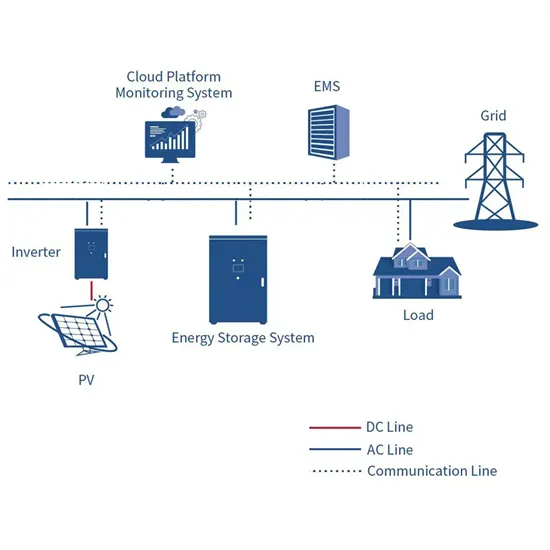

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

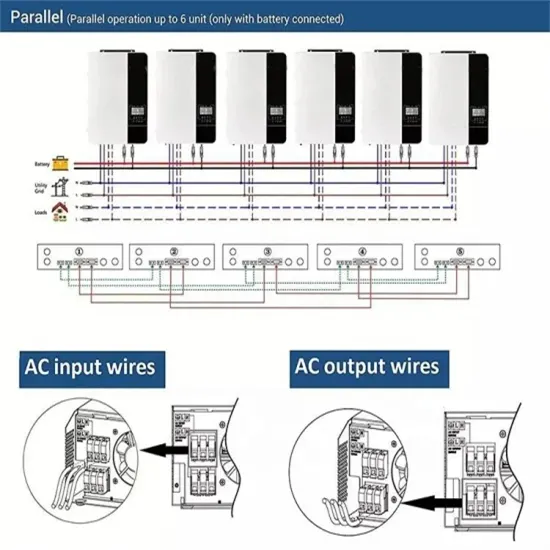

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.