How to solder lithium battery packs

How do you solder a battery pack? Step 1: Disassemble the battery pack, if you need to, so you can get to the cells. Step 2: Clean the cell ends so that when you solder, you will be able to

Get Started

Revive Your Dead Lithium Battery Pack with

Mar 23, 2023 · The repair of a lithium battery pack is an important task that requires technical knowledge and skill, but luckily, with some basic knowledge

Get Started

Do Not Use A Soldering Iron to Solder Lithium Battery Cells

Apr 26, 2024 · Until now, some people still use soldering irons to solder lithium batteries. They find it very convenient and feel that they can be used normally after the battery pack comes

Get Started

Tutorial: Soldering Li-Ion Battery Cells (18650,

Jan 2, 2020 · Soldering Li-ion batteries, such as 18650 cells, can be dangerous. Overheating may cause the battery to catch fire and explode. If you decide to

Get Started

Lithium Battery Pictures, Images and Stock Photos

Search from 16,500 Lithium Battery stock photos, pictures and royalty-free images from iStock. For the first time, get 1 free month of iStock exclusive

Get Started

Spot Welding vs Soldering 18650 and 21700 Batteries: Pros,

Compare spot welding and soldering methods for connecting 18650 and 21700 batteries. Learn about the advantages, disadvantages, safety considerations, and best practices for each

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · From precise cell welding to smart BMS integration—uncover how lithium-ion battery packs are engineered for safety and power.

Get Started

What materials should be used for lithium battery

To solder a lithium battery,you''re going to need at least 100 wattsof power at the tip. Having triple-digit watts at your disposal is required to be able to get in there,form an excellent

Get Started

How to Solder Lithium Battery? E-bike Batteries

The soldering of e-bike battery is used to connect batteries. Two methods: an automatic spot soldering machine; a soldering iron (handheld)

Get Started

[Step Guide ] How to Solder Multiple Lithium Batteries?

Jul 7, 2025 · Learn step-by-step how to solder lithium batteries in series or parallel safely and effectively with this detailed, hands-on guide.

Get Started

DIY LiFePO4 Battery Pack : 14 Steps (with

DIY LiFePO4 Battery Pack: In the past few years, the cost of solar panels are decreasing drastically but the overall cost of the Off-Grid solar system is still

Get Started

Making a Li-Ion battery pack

Jun 6, 2020 · Before we can add solder to the cells, we need to remove the oxidised layer from the cells. I do this by scraping carefully with a knife. But the cell flat on the table and start

Get Started

DIY Guide: Building a 12V Lithium Ion Battery Pack from

Feb 5, 2025 · Carefully connect the lithium-ion battery cells in series using nickel strips and a spot welder or soldering iron. Be cautious to follow the correct polarity to avoid short circuits.

Get Started

How To Make Soldering Iron With Battery?

Mar 5, 2025 · The market offers various off-the-shelf battery-powered soldering irons, ranging from compact, low-power models to more robust, professional-grade units. However, these

Get Started

Tutorial: Soldering Li-Ion Battery Cells (18650,

Jan 2, 2020 · To accomplish this, use a powerful, temperature-controlled soldering iron. A less powerful iron won''t maintain its temperature as

Get Started

How To Make A Battery Powered Soldering Iron?

Jan 8, 2025 · Battery Pack Assembly: Solder the 18650 cells together in series (and parallel if you need more capacity) using nickel strips or a dedicated 18650 holder. Weld or solder the nickel

Get Started

How to solder lithium battery packs

How to solder lithium batteries? If you are going to solder lithium batteries, apply lots of flux to the cell before touching it with the soldering iron. This will ensure that the cell surface is in the best

Get Started

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

Get Started

Soldering 18650 Batteries-Methods and Safety-battery

Jan 2, 2020 · A 18650 is a lithium-ion rechargeable battery and properly named as "18650 cell". The cell has a nominal voltage of 3.7 volts. The 18650 batteries are commonly found in

Get Started

Can You Solder 18650 Batteries? The Pros, Cons,

Jan 5, 2025 · In this detailed guide, as a professional 18650 battery manufacturer, I''ll cover everything you need to know about soldering 18650 lithium-ion

Get Started

How to Effectively Solder 18650 Batteries: Tips and

Feb 21, 2025 · Soldering Iron: A powerful iron (60W or more) with a wide tip for effective heat transfer. Solder: Use rosin-core leaded solder, which flows well and provides strong joints.

Get Started

How to solder lithium battery power line with soldering

Description Solder on the go. The TOPEX 4V Max cordless soldering iron is a high performance cordless soldering iron with a rechargeable lithium-ion battery. It can stay on for up to 30

Get Started

Spot Welding vs Soldering for Lithium Batteries:

Aug 8, 2025 · Spot welding fuses metal tabs using heat and pressure, providing fast, durable connections ideal for large-scale lithium battery manufacturing. In

Get Started

Powering Up Safely: How to Wire Batteries in Series

Nov 15, 2023 · Wiring lithium-ion batteries in series is a common practice to increase overall voltage, but requires careful attention to detail and adherence to safety guidelines. Always

Get Started

Top 8 Best Battery Powered Soldering Irons

Weller is a known name in soldering iron products. This particular model has a rechargeable lithium-ion battery that provides up to 45 minutes of soldering.

Get Started

Building Your Own Lithium Battery Pack: A Step-by-Step

Feb 9, 2025 · Lithium batteries are becoming an essential part of everyday technology. From powering smartphones and laptops to electric vehicles and renewable energy systems, their

Get Started

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Get Started

How to Make a Lithium Battery for an Electric

How to Make a Lithium Battery for an Electric Bicycle: Electric bicycles use batteries made from lithium ion cells. One of the most common types is a

Get Started

Technician use soldering iron to solder metal and wire of lithium

Technician use soldering iron to solder metal and wire of lithium-ion rechargeable battery. Repair module of Li-ion battery. Engineer hand holds soldering iron and tin-lead to solder electronic

Get Started

18650 best soldering technique?

Jul 7, 2020 · The "never solder to cells" warning is in datasheets, which are targeted at battery professionals (engineers, pack manufacturers, etc) who are presumed to already have

Get Started

Do Not Use A Soldering Iron to Solder Lithium

Apr 26, 2024 · Until now, some people still use soldering irons to solder lithium batteries. They find it very convenient and feel that they can be used normally

Get Started

User Constructed Lithium Battery Powered Soldering Iron

I decided to put it all together to build my own battery powered Soldering iron in one Sunday afternoon. The image shows a older case of a 1990 power screwdriver that had two Ni-Cad

Get Started

How to Make a Lithium-Ion Battery Pack

Mar 16, 2025 · Learn how to assemble lithium-ion battery pack. Explore essential steps, safety precautions, and necessary components.

Get Started

6 FAQs about [Use soldering iron to produce lithium battery pack]

How to solder lithium batteries?

If you are going to solder lithium batteries, apply lots of flux to the cell before touching it with the soldering iron. This will ensure that the cell surface is in the best possible state to be soldered which will require less soldering time for a good connection. In this article, we will discuss how to solder lithium batteries.

How do you solder a battery pack?

Step 1: Disassemble the battery pack, if you need to, so you can get to the cells. Step 2: Clean the cell ends so that when you solder, you will be able to make a secure, strong connection. Step 3: Turn on the soldering iron and allow it to heat up all the way.

What happens if you solder a lithium battery?

The problem with soldering lithium batteries is that the heat from the soldering process damages the cells to some degree. Not only does it damage the cells, but it damages the cells to an inconsistent degree in most cases. This can cause the battery pack to come out of balance later on.

How do you solder a battery with a soldering iron?

“Tin” both sides of the batteries with a small amount of solder, allowing it to cool down before soldering the wires. Keep the time your soldering iron touches the battery terminals to a minimum. The longer the iron is in contact with the battery, the more heat will build up.

Does a soldering iron heat up a battery?

Keep the time your soldering iron touches the battery terminals to a minimum. The longer the iron is in contact with the battery, the more heat will build up. To accomplish this, use a powerful, temperature-controlled soldering iron.

How much power do you need to solder a lithium battery?

To solder a lithium battery, you’re going to need at least 100 watts of power at the tip. Having triple-digit watts at your disposal is required to be able to get in there, form an excellent connection, and get you- quick. It may seem counter-intuitive, but the best soldering iron-to-solder lithium-ion batteries is going to be the hottest one.

Related Articles

-

Bare charging of lithium iron phosphate battery pack

Bare charging of lithium iron phosphate battery pack

-

Lithium iron phosphate battery pack dc576v

Lithium iron phosphate battery pack dc576v

-

Lithium iron phosphate battery pack forced charging

Lithium iron phosphate battery pack forced charging

-

Chad lithium iron phosphate battery pack wholesale

Chad lithium iron phosphate battery pack wholesale

-

Produce 12v40ah battery pack using lithium battery

Produce 12v40ah battery pack using lithium battery

-

The lithium battery pack loses power halfway through use

The lithium battery pack loses power halfway through use

-

60v lithium battery pack should I use 21 or 20 strings

60v lithium battery pack should I use 21 or 20 strings

-

60v lithium iron phosphate battery semi-finished battery pack

60v lithium iron phosphate battery semi-finished battery pack

-

How much does it cost to produce a lithium battery pack

How much does it cost to produce a lithium battery pack

-

UPS and lithium iron phosphate battery pack

UPS and lithium iron phosphate battery pack

Commercial & Industrial Solar Storage Market Growth

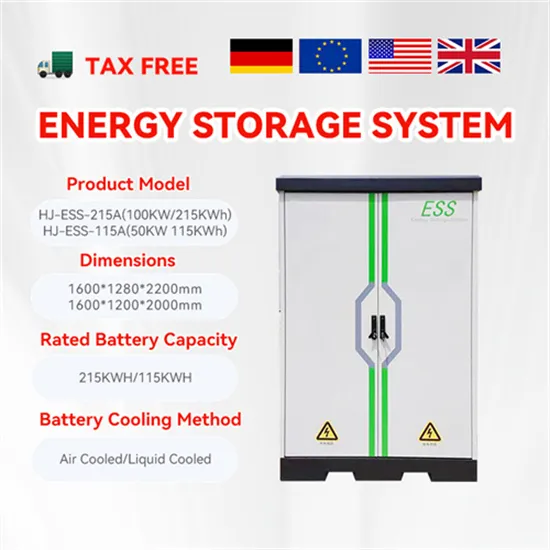

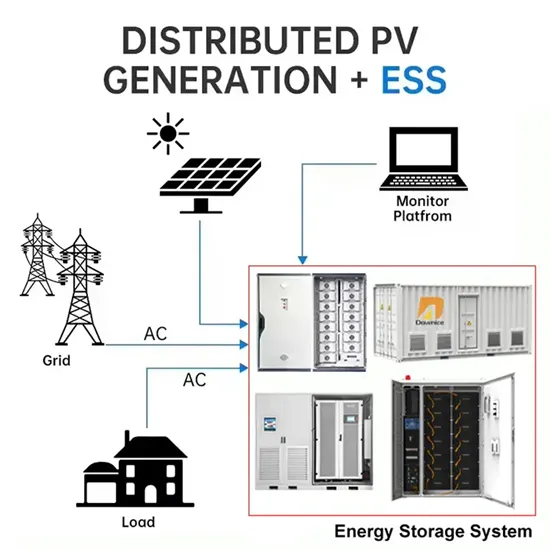

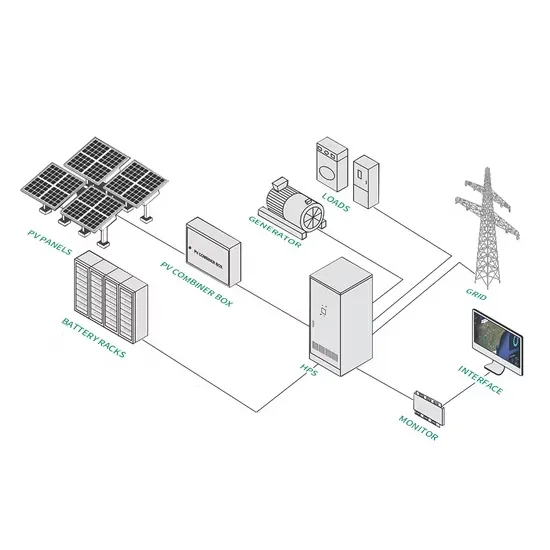

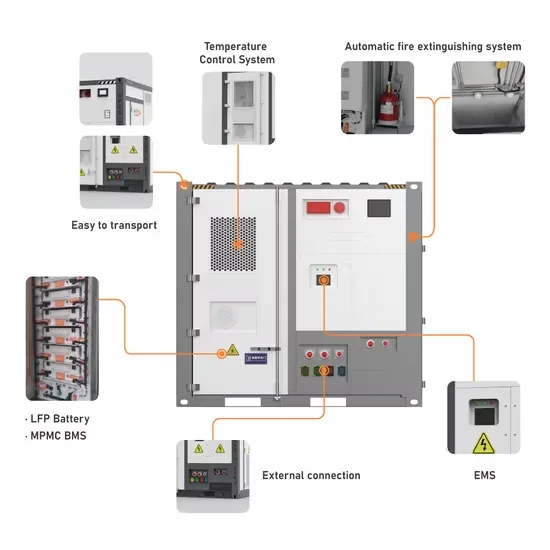

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

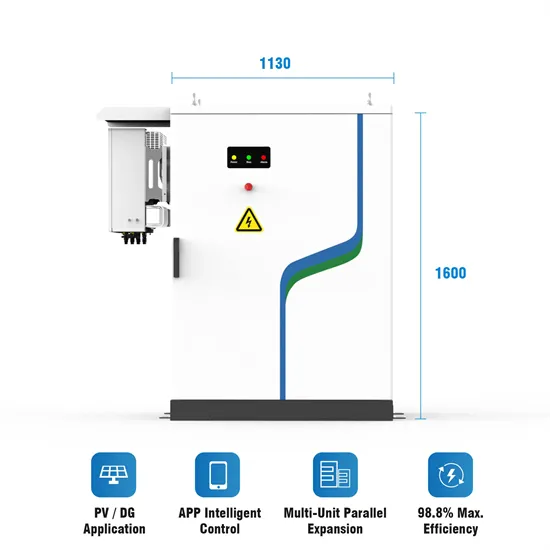

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.