BATTERY CABINET COOLING SYSTEM PRINCIPLE DIAGRAM

Battery cabinet plastic parts materials A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the batteryand all its accessories from the external

Get Started

Ventilation and Thermal Management of Stationary

Jan 10, 2023 · The purpose of the document is to build a bridge between the battery system designer and ventilation system designer. As such, it provides information on battery

Get Started

Battery cabinet cooling system working principle

sign key points of power battery cooling system. The excellent power battery cooling system can effectively control battery the temperature, improve the safety, performance and service life of

Get Started

Active cooling techniques for battery thermal management

Jan 1, 2024 · This chapter presents an overview of different active cooling techniques for battery thermal management systems, including liquid and nanofluid, forced air, refrigeration,

Get Started

What Is Battery Liquid Cooling and How Does It

5 days ago · Battery thermal management systems impact vehicle safety and performance. Electric vehicle owners want to be reassured about their cars''

Get Started

EV Battery Cooling System – How Does It Work?

Mar 10, 2025 · Learn how EV battery cooling system protect performance and safety. Explore methods, challenges, and best practices.

Get Started

(PDF) Stationary Battery Thermal Management:

Mar 1, 2022 · Following model validation, several cooling system configurations are analyzed in application to a full-scale stationary battery system.

Get Started

Air Cooling Concepts for Li-Ion Battery Pack in

Jul 9, 2017 · Computational Fluid Dynamics (CFD) modeling is used to study different cooling architectures for the next generation (Gen-2) EREV Li-Ion

Get Started

Presentazione standard di PowerPoint

Apr 15, 2021 · THE EVOLUTION OF THE COOLING – THE HYBRID SHELTER Passive cooling system is supported by an auxiliary air conditioner or chiller, activated only during the warmer

Get Started

Battery Energy Storage System Cooling

Kooltronic offers innovative cooling solutions for battery cabinets and electrical enclosures used in renewable energy storage systems. Click to learn more.

Get Started

100kW 215kWh All-in-One Battery Storage

The iCON 100kW 215kWh Battery Storage System is a fully integrated, on or off grid battery solution that has liquid cooled battery storage (215kWh), inverter

Get Started

New energy battery cabinet fan cooling principle

Does fan direction control improve cooling performance of battery packs? Cooling performance of battery packs under different design options. In summary,the thermal management strategy

Get Started

Microsoft Word

Mar 6, 2019 · The temperature differences (delta Ts) in a Passive Cooling System are much smaller than in an active air conditioner. That means that every °C, Kelvin or Fahrenheit is

Get Started

Thermal Regulation Techniques for EV Batteries

Jul 30, 2025 · Explore the latest innovations in EV battery thermal management during charging, ensuring overall safety, longevity, and optimal performance.

Get Started

Principle of outdoor liquid cooling energy storage cabinet

Outdoor liquid cooled and air cooled cabinets can be paired togetherutilizing a high voltage/current battery combiner box. Outdoor cabinets are manufactured to be a install ready

Get Started

How It Works: Battery Thermal Management

Jul 18, 2023 · Active Cooling: The L-CON BTMS incorporates an active cooling system that utilizes a liquid-cooled condenser to control the temperature of the

Get Started

Liquid cooling energy storage cabinet principle

Key Features of Battery Cabinet Systems. High Efficiency and Modularity: Modern battery cabinet systems, such as those from CHAM Battery, offer intelligent liquid cooling to maintain optimal

Get Started

EV Battery Cooling System – How Does It Work?

Mar 10, 2025 · What is the principle of battery cooling system? Managing heat is crucial for EV battery cells. Overheating can shorten battery life and

Get Started

215 kWh LFP Air Cooled Battery System | HISbatt

HISbatt 215-A comes with an integrated cooling system (HVAC), a fire suppression system, and a power inverter installed with the safest LFP battery

Get Started

What''s Active Cooling? Active Cooling vs.

Apr 18, 2024 · Active cooling techniques, such as liquid cooling and refrigeration systems, were developed to meet the increasing demands. If you need a fast

Get Started

Battery Liquid Cooling System Overview

Aug 15, 2025 · Electric motors, supercharging, fast charging, and related tech are innovating rapidly. This is creating big challenges for battery thermal

Get Started

Ventilation and Thermal Management of Stationary

Jan 10, 2023 · The subject of forced ventilation is covered in less rigor but the basic principles of supply and exhaust fans, negative pressure and how to size the system based on the worst

Get Started

Cooling Characteristics and Optimization of an Air-Cooled Battery

Jan 31, 2025 · Lithium-iron phosphate batteries are widely used in energy storage systems and electric vehicle for their favorable safety profiles and high reliability. The designing of an

Get Started

EV Battery Cooling: Key Applications and Impact

5 days ago · Battery thermal management systems leverage passive air cooling and active heat pump technology to maintain optimal battery temperature,

Get Started

Active Cooling Techniques for EV Battery Protection

Jul 30, 2025 · Efficient thermal management of lithium-ion batteries is crucial for electric vehicle safety and performance. This study investigates immersion cooling in serpentine channels

Get Started

The whole range of thermal management for the BESS industry

As electric vehicles and energy storage systems evolve, so do the challenges of managing heat during high-power charging. Without effective thermal management, excessive heat buildup

Get Started

Types of Battery thermal management Systems

Feb 18, 2024 · Battery thermal management (BTMS) systems are of several types. BTMS with evolution of EV battery technology becomes a critical

Get Started

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

By using a liquid coolant to absorb and dissipate heat directly from the battery modules, these systems can manage thermal loads far more effectively than air-based counterparts, ensuring

Get Started

6 FAQs about [Battery cabinet active cooling system principle]

What is an active battery pack cooling system?

1. INTRODUCTION An active battery pack cooling system using Peltier modules is a high-tech way to control and maintain battery pack temperature in various applications, including renewable energy storage systems, electric heat build-up.

What are active cooling systems?

Active cooling systems are a result of the search for a more intelligent and responsive solution. They are made to actively control a temperature and mitigate the negative consequences of coolant. When it is summer season, we need to cool a battery, if it is winter season, we need to heat a battery to certain temperature.

Why should a battery pack cooling system be active?

Enhanced System Reliability: Safety risks and system failures can result from overheating. By reducing these hazards, active cooling can help creating a battery system that is more dependable. The image of active battery pack cooling system maintained at an optimal temperature range and 3D printing is shown below.

How to set up a battery pack cooling system?

Assemble the parts of the battery pack cooling system. Set up the control circuits and Peltier module. To continuously check the battery temperature, use temperature sensors. Determine whether the battery temperature exceeds or subceeds the optimal range. If yes, start the Peltier module cooling system and Peltier module heating system.

How to maintain a constant temperature inside a battery pack system?

When the temperature inside a battery pack is suddenly increases, it gets explode. So we need to maintain a constant temperature inside the battery pack system. For that, we add a module called Peltier module(Thermoelectric) to the battery pack system. This module works on the principle of both cooling and heating process. It also works like

Why do EV batteries need cooling?

EV batteries need cooling to prevent overheating, ensure safe operation, and extend battery life. Without adequate temperature control, performance drops. Cells degrade faster, and there is a risk of thermal runaway. Cooling provides steady power flow and maintains a healthy battery chemistry.

Related Articles

-

Battery cabinet active safety technology

Battery cabinet active safety technology

-

Principle of variable pitch battery cabinet base station

Principle of variable pitch battery cabinet base station

-

New energy liquid cooling energy storage battery cabinet 80 degrees

New energy liquid cooling energy storage battery cabinet 80 degrees

-

Battery cabinet liquid cooling technical requirements

Battery cabinet liquid cooling technical requirements

-

Battery Cabinet Working Principle

Battery Cabinet Working Principle

-

Battery Cabinet Cooling Technology Comparison

Battery Cabinet Cooling Technology Comparison

-

Energy storage liquid cooling battery cabinet technology development

Energy storage liquid cooling battery cabinet technology development

-

Lithium battery energy storage cabinet principle

Lithium battery energy storage cabinet principle

-

Battery cabinet cooling system ESS power base station

Battery cabinet cooling system ESS power base station

-

Working Principle of Lithium Battery Station Cabinet

Working Principle of Lithium Battery Station Cabinet

Commercial & Industrial Solar Storage Market Growth

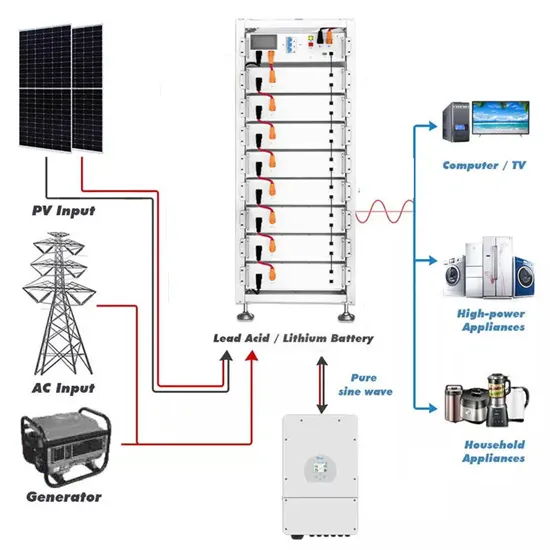

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.