Learn About the Different Types of Battery

Mar 28, 2025 · Discover different battery packaging types, safety rules, and how proper packaging impacts performance. Learn about lithium, solar, car battery

Get Started

Humidity requirements for battery production workshop

Now let''''s look at the requirements for battery production, which is a typical use of a dry room. Because of the material sensitivity, solid-state battery dry rooms may need humidity controlling

Get Started

Optimal Storage Conditions for Batteries: Temperature etc.

Oct 10, 2024 · Batteries should be stored in cool, dry environments with temperatures between 15°C and 25°C (59°F -77°F) and humidity levels below 60%. Extreme temperatures or high

Get Started

Production & Testing Solutions Battery & EV Requirements

Apr 11, 2025 · Temperature & Humidity Environmental Testing Often referred to as temperature cycling, or thermal testing, temperature and humidity stress testing is a process of cycling

Get Started

Do Lithium Ion Batteries Require A Battery Room? Storage Requirements

Apr 16, 2025 · In summary, lithium-ion batteries do not always require a dedicated battery room; however, proper storage requirements, including temperature, humidity, and ventilation, are

Get Started

Li-Ion Battery Safe Temperature: Everything You

May 28, 2025 · Discover safe lithium-ion battery temperature limits for charging, storage, and cold weather performance.

Get Started

Effect of Humidity on Properties of Lithium-ion Batteries

May 1, 2021 · A study was performed to determine the cause of abnormal direct current resistance (DCR) during high-temperature storage of a commercialized lithium-ion battery (1C=50 Ah)

Get Started

Monitoring and control of internal temperature in power

Feb 1, 2025 · Compared to external temperature monitoring and control of batteries, internal temperature monitoring and control can more realistically and directly display the temperature

Get Started

5 Best Practices for Storing Lithium-Ion Batteries

Jul 11, 2023 · How to safely store lithium-ion batteries and extend lithium-ion battery cycle life? This is the 5 best way to store lithium-ion batteries.

Get Started

Lithium Battery Temperature Ranges: Operation

Aug 13, 2025 · Learn optimal lithium battery temperature ranges for use and storage. Understand effects on performance, efficiency, lifespan, and safety.

Get Started

Product Specification 20kW-100kWh Battery Energy

Jan 15, 2025 · I. Scope of Application This specification is suitable for the 20KW/100KWh energy storage system developed by Anhui Lvwo Energy Technology Co., Ltd. It describes its

Get Started

Thermal management requirements in battery packs: An

Aged battery packs were found to exhibit higher temperature rises and larger thermal gradients. Enhanced cooling reduces average temperature but enlarges temperature gradients,

Get Started

Investigating an influence of temperature and relative humidity

Jun 23, 2022 · Lithium-ion batteries suffer from insufficient electrical performance due to the unpredictable thermal effect and dynamic behaviour during the charging and discharging

Get Started

Lab Battery Pack Reliable Temperature Humidity Cycle Climate

Feb 11, 2025 · Through the cooperation of these systems, the test chamber can operate stably within the set temperature and humidity range. The test chamber adopts advanced

Get Started

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Uncertainty in the measurement of key battery internal states, such as temperature, impacts our understanding of battery performance, degradation and safety and underpins

Get Started

Must-Have Sensors for EV Battery Packs & Cell

Aug 11, 2025 · Integrated sensor technology enhances the performance, safety, and efficiency of EV battery packs and cell connection systems – key

Get Started

Maximum temperature analysis in a Li-ion battery pack

Aug 3, 2020 · This analysis is a novel study which considers different categories of coolant and conjugate heat transfer condition at the battery pack and coolant interface. In each group of

Get Started

Temperature and Humidity Characteristics Analysis with Heat

Apr 24, 2022 · The Power Battery Pack (PBP) is a semi-sealed high-energy storage device with the internal cold and heat source, and the components inside the PBP face moisture and

Get Started

Comprehensive Guide to Lithium Battery Temperature

10 hours ago · Effective lithium battery temperature management protects your battery packs from dangerous failures and costly downtime. Poor temperature management can trigger thermal

Get Started

High-Temperature and Humidity Battery Safety Testing with

Aug 14, 2025 · This article distills the relevant requirements from these standards, translates them into actionable test profiles, and maps each to suitable LIB temperature and humidity

Get Started

Environmental Testing of Batteries

Vibration and shock testing, with or without parallel temperature/humidity tests in simultaneous electric operation Thermal testing, including high-temperature, thermal shock and thermal

Get Started

Understanding NFPA 855 Standards for Lithium

Apr 25, 2025 · NFPA 855 lithium battery standards ensure safe installation and operation of energy storage systems, addressing fire safety, thermal runaway,

Get Started

Electrical Insulation in a 400 V Battery Module for Hybrid

Nov 25, 2022 · In this work the results from the insulation resistance tests, partial discharge tests and en-vironmental tests performed on a battery system are presented. The results from

Get Started

Cleanrooms for EV Battery Production | ACH

Aug 19, 2025 · What are the Temperature and Humidity Requirements? How Will Particulate and Contaminant Control be Achieved? The design of a cleanroom

Get Started

UPS & Battery Room Cooling | PDF

Mar 20, 2024 · 1) The document discusses ventilation and cooling recommendations for UPS and battery rooms in data centers. Maintaining the

Get Started

BMS Requirements

Application-Specific Requirements Tailoring a Battery Management System (BMS) to meet application-specific prerequisites assumes paramount importance, as these requirements

Get Started

Lithium-ion battery pack thermal management under high

Mar 1, 2024 · To ensure the stable operation of lithium-ion battery under high ambient temperature with high discharge rate and long operating cycles, the phase cha

Get Started

Giga Factory Electric Vehicle Battery Facilities

May 3, 2023 · Dew Points in these EV Battery Clean & Dry rooms vary depending on the particular process requirement. Many are -40°C, which equates to less

Get Started

Complete Guide: Lithium-ion Battery Storage

Apr 19, 2024 · Temperature plays a vital function in the fitness of stored batteries. The ideal temperature for lengthy-time period storage of lithium-ion batteries is

Get Started

Lithium Battery Humidity Test & Battery Testing Solutions.

May 27, 2025 · For EV battery manufacturers, passing lithium battery humidity test protocols is essential to meet global safety certifications. Key standards like GB/T 36276-2023 mandate

Get Started

Review on Battery Packing Design Strategies for

Dec 14, 2022 · An optimal battery packing design can maintain the battery cell temperature at the most favorable range, i.e., 25–40 °C, with a temperature

Get Started

Optimal storage temperature and humidity for lithium

4 days ago · Storing lithium batteries at 15–25°C and 30–50% RH isn''t just about specs—it''s about peace of mind. Whether you''re protecting a 1,500powertoolbatteryora 50,000 EV battery

Get Started

Battery curing temperature requirements

The present invention discloses a lead acid battery plate curing process, characterized in that: the curing process is divided into three stages, moisture curing stage, solidification stage and

Get Started

Battery Pack Assembly Cleanroom Requirements

Jul 15, 2025 · Effective battery pack assembly cleanrooms require meticulous attention to ISO classification standards, airflow design, material compatibility, and personnel protocols to

Get Started

6 FAQs about [Battery pack temperature and humidity requirements]

How much humidity should a battery have?

Ideal storage conditions should maintain humidity levels below 60% to prevent corrosion and damage. Batteries exposed to high humidity can develop rust or leaks, which are hazardous. It is also important to store batteries at a partial charge. The recommended charge level for long-term storage is between 30% to 50%.

What temperature should a battery be stored at?

Temperature plays a vital function in the fitness of stored batteries. The ideal temperature for lengthy-time period storage of lithium-ion batteries is typically between 10°C and 25°C (50°F to 77°F). Extreme temperatures, both warm and cold, need to be prevented as they can boost the degradation of the battery.

Why is temperature management important for lithium-ion batteries?

Proper temperature management is critical in the robust storage of lithium-ion batteries. Properly storing lithium-ion batteries is vital for maintaining their longevity and protection. Favorable conditions must be meticulously maintained for lengthy-term storage to save you from degradation and preserve battery fitness.

What is a good battery packing design?

An optimal battery packing design can maintain the battery cell temperature at the most favorable range, i.e., 25–40 °C, with a temperature difference in each battery cell of 5 °C at the maximum, which is considered the best working temperature. The design must also consider environmental temperature and humidity effects.

How does humidity affect lithium ion battery storage?

How does humidity impact lithium-ion battery storage? High humidity can lead to corrosion and degradation of lithium-ion batteries, while low humidity can increase the risk of static energy build-up. Maintaining an ambient relative humidity between 30% and 50% is ideal for battery storage.

Are there guidelines for storing lithium-ion batteries at home?

Yes, there are unique guidelines for storing lithium-ion batteries at home. Proper storage practices ensure the safety and longevity of the batteries. These guidelines help mitigate the risks of fire, overheating, and reduced battery lifespan. Storing lithium-ion batteries requires attention to temperature, humidity, and physical conditions.

Related Articles

-

Argentina lithium battery pack low temperature charging and discharging

Argentina lithium battery pack low temperature charging and discharging

-

Santo Domingo low temperature lithium battery pack

Santo Domingo low temperature lithium battery pack

-

Bahrain wide temperature lithium titanate battery pack

Bahrain wide temperature lithium titanate battery pack

-

High temperature lithium battery pack

High temperature lithium battery pack

-

Kigali PACK Battery Factory

Kigali PACK Battery Factory

-

What is the battery trial production PACK

What is the battery trial production PACK

-

Lithium battery pack processing in Portugal

Lithium battery pack processing in Portugal

-

What brand of lithium battery pack is good

What brand of lithium battery pack is good

-

Energy storage battery cabinet storage environment requirements

Energy storage battery cabinet storage environment requirements

-

Ecuador lithium battery pack OEM manufacturer

Ecuador lithium battery pack OEM manufacturer

Commercial & Industrial Solar Storage Market Growth

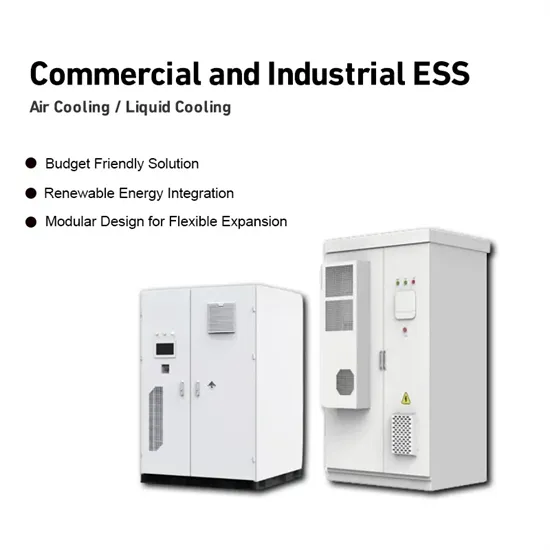

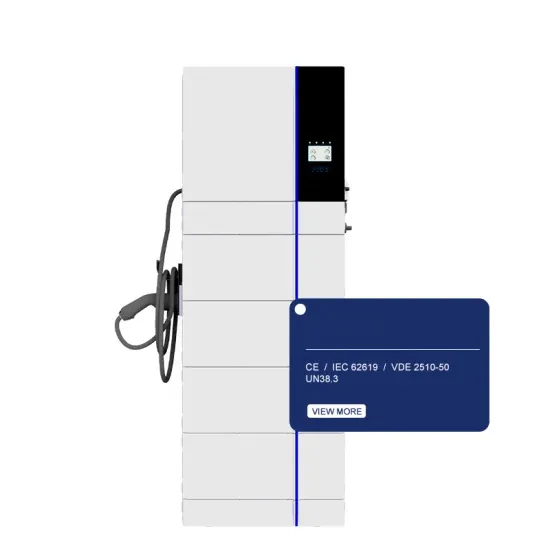

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

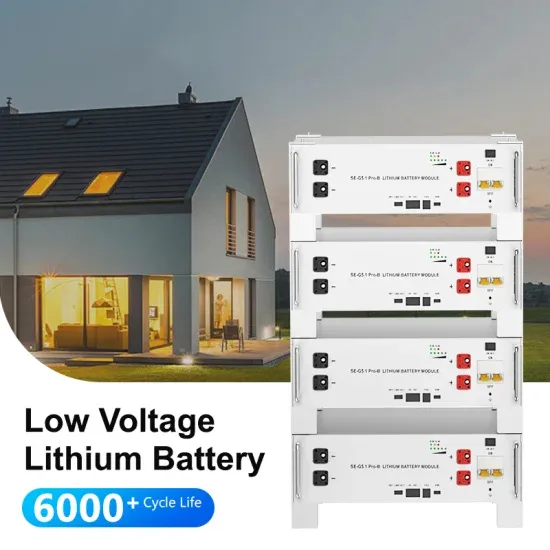

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.