Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Introduction The battery pack assembly process is a cornerstone of modern manufacturing, essential for producing high-performance battery

Get Started

20 companies'' solid-state battery mass production "timetable"

Jul 16, 2024 · In recent years, with the vigorous development of the new energy vehicle market, solid-state batteries, as the core of the next generation of power battery technology, are

Get Started

Tesla begins trial production at Shanghai

Dec 31, 2024 · After just about seven months of construction, Tesla has officially completed its Shanghai, China factory for its Megapack grid-scale batteries,

Get Started

Battery Pack Manufacturing Process

Mar 15, 2025 · Battery packs power everything from electric vehicles to smartphones. But have you ever wondered how they''re made? The battery

Get Started

Explained: Our battery plant design and

Aug 9, 2024 · Our battery plant and simulation trial will show you how a battery module and pack assembly line can be updated within a gigafactory using

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

Stellantis Validates Game-Changing Solid-State

Stellantis Validates Game-Changing Solid-State Battery After ''Production Hell'' The pack will be installed in a demonstration fleet of the Dodge Charger

Get Started

EV Battery-Pack Manufacturing Packs | DigiKey

Apr 14, 2023 · The battery pack is a critical subassembly in all-electric vehicles (EVs), and it''s one of the most complex to assemble. It starts with testing the

Get Started

Samsung unveiled mass-production readiness

Mar 18, 2024 · Samsung SDI announced its participation in InterBattery 2024 that kicks off on March 6 for a three-day run in Seoul. The company is poised to

Get Started

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Current manufacturing processes for LIBs LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature

Get Started

The Camel Group North American Automotive Battery Plant

Jul 20, 2023 · Founded in 1980, Camel Group Co., Ltd. is specialized in the R&D, production and sales of lead-acid batteries, with the production of EV lithium-ion battery and used battery

Get Started

China''s Svolt to Begin Trial Production of Semi-Solid-State Batteries

Jul 24, 2025 · Chinese battery manufacturer Svolt Energy is set to launch trial production of its first-generation semi-solid-state batteries in the fourth quarter of 2025, with plans to supply the

Get Started

Vehicle Trial Production Center

Apr 7, 2025 · Energy Storage Unit Trial Production line The concept of battery package trail production line is be provided and covers material inspection, battery cell selection, battery

Get Started

Vehicle Trial Production Center

Apr 7, 2025 · Energy Storage Unit Trial Production line The concept of battery package trail production line is be provided and covers material inspection, battery cell selection, battery

Get Started

Tesla starts trial production at Shanghai Megapack

Jan 2, 2025 · Tesla has announced the commencement of trial production at its newly constructed Megapack manufacturing facility in Shanghai, China. The plant represents Tesla''s first

Get Started

Svolt Energy targets Q4 for semi solid state battery trial production

Jul 24, 2025 · These semi-solid batteries, characterized as soft-pack with an energy density of 300 Wh/kg and cost-effectiveness, are intended for BMW''s Mini brand''s upcoming models,

Get Started

Tesla''s Megapack factory in Shanghai begins

Jan 1, 2025 · Tesla''s energy storage Megafactory in Shanghai has commenced trial production of its Megapacks large-scale energy storage batteries, with full

Get Started

All-solid-state battery technology|Honda

Jun 11, 2025 · What is an all-solid-state battery? Striving for a safe and high-capacity battery with excellent output characteristics Lithium-ion batteries for

Get Started

Tesla''s Megapack factory in Shanghai begins

Jan 1, 2025 · The Shanghai Megafactory is Tesla''s first production site for Megapacks – its second facility in Shanghai – outside the United States, with

Get Started

Tesla''s Shanghai Megapack energy storage plant

Dec 31, 2024 · The battery factory marks the company''s first energy storage system factory outside the US to manufacture its energy storage batteries

Get Started

Evaluation of the safety standards system of power batteries

Nov 1, 2023 · China''s existing battery safety standards mainly focus on post-production battery testing, namely the mechanical abuse, electrical abuse, thermal abuse, and environmental

Get Started

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

Get Started

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Get Started

Cell Sample Maturity

Jul 19, 2022 · Cell Sample Maturity is normally defined by the A, B, C, D sample definitions, fixing the cell design to establish performance is crucial.

Get Started

Explained: Our battery plant design and

Aug 9, 2024 · Explained: Our battery plant design and simulation trial Battery companies that want to grow rapidly need to be able to plan for multiple

Get Started

Vehicle Trial Production Center

Apr 7, 2025 · The concept of battery package trail production line is be provided and covers material inspection, battery cell selection, battery module assembly, internal resistance testing,

Get Started

Tesla''s Shanghai Megapack energy storage plant

Dec 31, 2024 · US electric car producer Tesla''s Shanghai Megapack energy storage plant has begun trial production and is expected to start mass

Get Started

Technical specifications and test protocols for the battery

Mar 29, 2021 · 1. Introduction The objective of this deliverable is to document the system specifications, based on the requirements gathered and documented D1.1 Consolidated

Get Started

Tesla''s Shanghai energy storage megafactory

Jul 31, 2025 · The new plant is dedicated to manufacturing Megapacks, Tesla''s energy-storage batteries, with mass production expected to commence fully in

Get Started

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production. In this article, we will

Get Started

Direct recycling of Li-ion batteries from cell to

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

Get Started

Tesla Patents Low-Cost LFP Battery

Jan 17, 2025 · Lithium iron phosphate or LFP is at the heart of new technologies for electric vehicle manufacturers. Now, Tesla has developed a potentially

Get Started

Ganfeng Lithium''s 12GWh Energy Storage Battery PACK

Jun 26, 2025 · On June 23, Jiangxi Ganfeng Lithium Battery''s New Battery Research Institute and PACK Integration Project is nearing trial production. Currently, four core factory buildings have

Get Started

Battery pack simulation | Siemens Digital Industries Software

Pre-size the battery to achieve the desired range and performance Rapidly determine the effect of operating conditions on battery temperatures Simulate and analyze the thermal runaway

Get Started

CATL ups bet on all-solid-state batteries, begins

Nov 6, 2024 · CATL has recently entered the trial production stage of 20 Ah samples, meaning the battery solution is initially finalized and it is starting to

Get Started

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Intercon

Get Started

Tesla Begins Trial Production at Shanghai Megapack Plant

Jan 8, 2025 · The factory, completed in December 2024, is expected to achieve mass production in early 2025, with an annual output of 10,000 Megapack units, equivalent to 40 GWh of

Get Started

6 FAQs about [What is the battery trial production PACK]

What are the three parts of battery pack manufacturing process?

Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In this article, we will look at the Module Production part.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

Related Articles

-

What equipment does a lithium battery pack require

What equipment does a lithium battery pack require

-

What does BMS battery pack mean

What does BMS battery pack mean

-

What brand of lithium battery pack do you use

What brand of lithium battery pack do you use

-

What to do if battery cabinet production causes pollution

What to do if battery cabinet production causes pollution

-

What brand of lithium battery pack is good

What brand of lithium battery pack is good

-

What is mylar in the battery pack

What is mylar in the battery pack

-

What are the energy storage battery production equipment

What are the energy storage battery production equipment

-

New Zealand Auckland RV lithium battery pack

New Zealand Auckland RV lithium battery pack

-

What should I pay attention to when buying a large battery cabinet

What should I pay attention to when buying a large battery cabinet

-

Caracas portable energy storage battery pack

Caracas portable energy storage battery pack

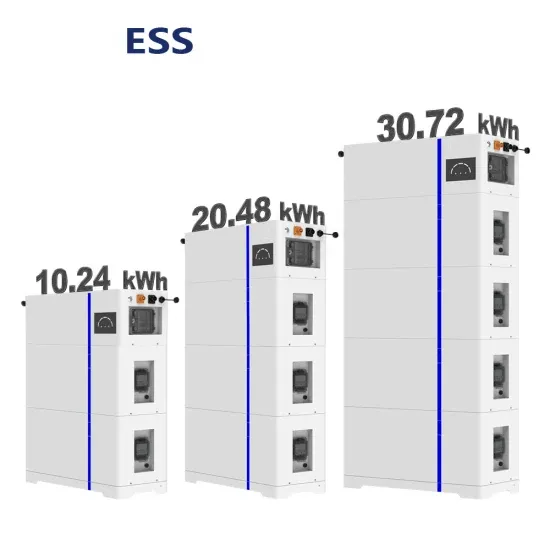

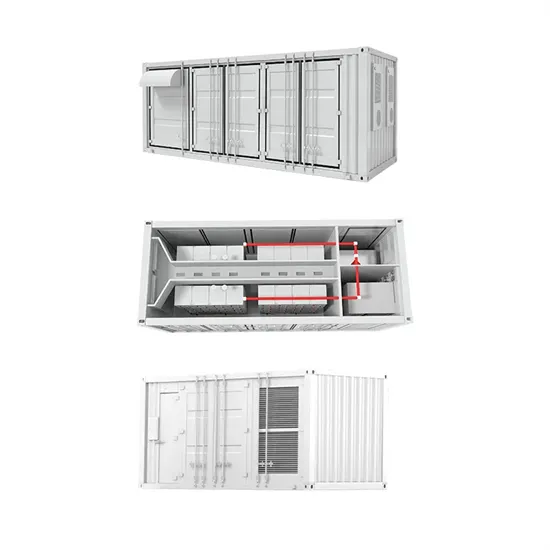

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.