Lithium Battery Labels 101: A Beginner''s Guide

Jan 22, 2025 · When it comes to shipping lithium batteries, it''s important to understand the specific labeling requirements to ensure the safe and

Get Started

Your 2025 Guide to Lithium Battery Labels

Mar 9, 2025 · There are many rules and regulations in place when it comes to applying battery labels to packages containing lithium batteries for transport.

Get Started

Do I Need a Lithium Battery Label for Shipping?

Aug 16, 2022 · The proper use of a lithium battery label for shipping is a crucial safety practice that every business and personnel in the shipping industry

Get Started

Why Do Lithium Batteries Require A Safety Data

Sep 9, 2022 · Lithium-ion batteries are one of the most useful products in electronic goods. Read the blog on why lithium batteries require a Safety Data

Get Started

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

Get Started

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Started

Lithium Battery Guide for Shippers | PHMSA

Nov 21, 2024 · This publication directs readers to scenario-based shipping guides that outline the requirements to ship packages of lithium cells and batteries in various configurations. Each

Get Started

Battery Shipping: Classification, Best Practices,

Apr 4, 2024 · This guide explains everything you need to know to stay compliant and avoid costly delays – from battery classifications to mode-specific rules

Get Started

A Comprehensive Guide to Lithium Ion Battery

Jul 3, 2023 · Professional and fast registration lithium-ion battery certificate, which is a top priority for CMB custom battery pack.

Get Started

What is a Lithium-Ion Battery and How Does it

Apr 8, 2025 · What is a Lithium-Ion Battery and How Does it Work? Explore lithium-ion battery types, how they work, cell formats, safety advancements,

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · These battery packs are critical components in electric vehicles (EVs), energy storage systems, and various portable electronic devices. 1.

Get Started

Do Lithium Batteries Require a Safety Data

Aug 13, 2021 · Learn whether it is required to have an SDS for lithium batteries & how to keep your workplace safe from battery leaks, spills & breaks.

Get Started

Lithium Battery Guide

Nov 21, 2024 · Effective May 10, 2024, the latest rulemaking (HM-215Q, published April 11, 2024) extends the requirement that lithium ion batteries must be marked with the Watt-hour rating on

Get Started

2020 Lithium Battery Guidance Document

Jan 8, 2020 · The employer must identify the different configurations of lithium batteries that they ship, i.e. lithium batteries and/or lithium batteries packed with equipment and/or lithium

Get Started

Beginners guide to UN3480, UN3481 and IATA

Nov 26, 2024 · If you need to ship lithium batteries safely and legally but dont know where to start, this beginners guide to UN3480, UN3481 & IATA

Get Started

Battery Certifications: Mandatory, Optional,

Battery Certifications: Mandatory, Optional, & The Unknown By Anton Beck, Battery Product Manager Epec Engineered Technologies When developing a

Get Started

Ultimate Guide to Equipment for Lithium Battery Assembly

Jan 23, 2025 · Lithium battery assembly equipment refers to the machinery and tools used in the production and assembly of lithium-ion batteries. This equipment is essential for ensuring the

Get Started

LITHIUM BATTERIES 101

Apr 28, 2022 · What are lithium (ion) batteries made of? Lithium (ion) battery building blocks How much lithium is in a typical Lithium battery? Lithium battery raw materials How does a lithium

Get Started

Clean Room atmosphere requirements for

Apr 26, 2024 · The core processes in lithium-ion battery manufacturing such as electrode manufacturing (steps 2 and 7) and battery cell assembly (step 8) are

Get Started

Lithium Battery PACK Production Line Processes

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Started

DOT Regulations for Lithium-Ion Battery Transport

Learn how to comply with DOT regulations for lithium-ion batteries. Discover safety, packaging, and labeling requirements in this guide.

Get Started

BIS Certification for Lithium-Ion Battery

Aug 16, 2022 · BIS has implemented regulations for Lithium-Ion Batteries that cover these products under the CRS Scheme. Check the procedure, documents required and more.

Get Started

Battery Pack Certifications – Costs, Timelines and Key

The result: a faster path to market, reduced costs, and total confidence in your product''s compliance. Lithium battery safety is at the top of the list for anyone who manufactures custom

Get Started

Lithium Battery Shipping Overview

1 day ago · Lithium Battery Shipping Overview (also see 49CFR173.185) Lithium batteries are used in many electronic devices such as cameras, cell phones, laptop computers, medical

Get Started

Introduction to Production Equipment and Testing Methods for Lithium

Jul 13, 2025 · The production of lithium-ion battery packs requires several key pieces of equipment: Electrode Coating Machines: Used to coat the electrodes with active materials.

Get Started

Lithium Battery Pack Introduction to Common Equipment

Jan 30, 2024 · The production process of lithium battery pack involves many equipments, including mixing equipment, coating equipment, winding equipment, hot pressing equipment,

Get Started

A Complete Guide to Lithium Battery

Understand 2025 lithium battery transportation rules, including packaging, labeling, and compliance to ensure safe and legal shipping across all modes.

Get Started

Shipping Lithium-Ion Batteries: UN3480

4 days ago · Learn the essential regulations for shipping lithium-ion batteries (UN3480 & UN3481) to ensure safety and compliance in your logistics

Get Started

Battery Factory How to Build the Lithium-Ion

Feb 26, 2024 · Uncover the secrets of how lithium-ion battery pack processes and components are manufactured in lithium-ion battery factories.

Get Started

Cleanrooms for EV Battery Production | ACH

Aug 19, 2025 · For EV battery manufacturing, particularly in the context of lithium-ion battery cells and packs, the following general guidelines might apply: Cell

Get Started

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · CMB''s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate

Get Started

What Components Do I Need to Build My Own Lithium Battery Pack?

Jun 19, 2025 · Building your own lithium battery pack requires a precise selection of components and a well-organized assembly process. At Redway Battery, with over a decade of expertise in

Get Started

What equipment is required for lithium battery pack and lithium battery

Nov 12, 2019 · What equipment is required for lithium battery pack and lithium battery pack processing? The manufacture of lithium batteries can be divided into four stages: pole piece

Get Started

6 FAQs about [What equipment does a lithium battery pack require ]

What is a lithium battery pack?

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

What do we have for lithium-ion battery pack assembly?

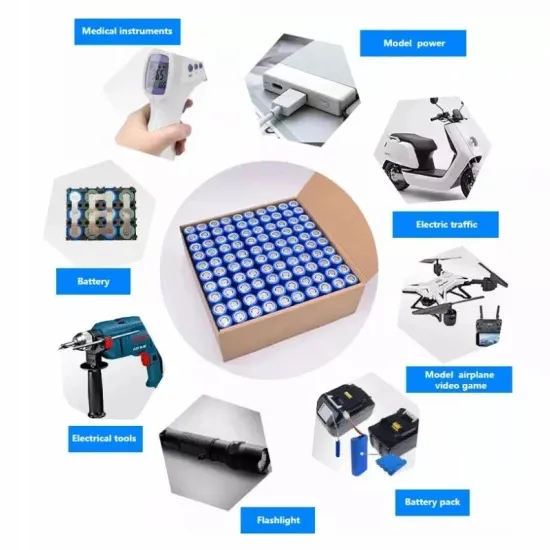

For lithium-ion battery pack assembly, we offer complete solutions. This includes different sizes of barley paper, battery cells, plastic holders, nickel strip, handheld spot welder, PVC, and high-temperature resistant adhesive tape. We also provide rolls of various widths and cut the length as per customer requirements.

What is used for insulation in lithium-ion battery pack assembly?

We have complete solution for lithium-ion battery pack assembly, including Insulation Barley Paper, PVC, High-temperature Resistant Adhesive Tape, etc.

Does pack & send deliver lithium batteries?

At PACK & SEND we can provide you with a complete packing and delivery service for lithium battery-powered equipment within the constraints of international regulations but be aware that this is a specialist and costly service and not appropriate for domestic lithium batteries not contained in their equipment.

What does it mean if a lithium ion battery is packed with equipment?

When a lithium ion battery is shipped with equipment, it means the batteries are being transported within the same package as the equipment they will be used with. Lithium batteries packed with equipment is different from lithium batteries contained in equipment, where the batteries are already installed in the device they are designed for. Other shipping requirements for lithium ion batteries include:

How many lithium batteries can be mailed in a package?

Lithium metal batteries contained in equipment meeting the provisions of Section II of Packing Instruction 970 of the IATA Regulations. No more than four cells or two batteries may be mailed in any single package. Lithium battery mark labels are not required for packages that contain no more than four cells or two batteries contained in devices.

Related Articles

-

What brand of lithium battery pack do you use

What brand of lithium battery pack do you use

-

Baghdad lithium battery pack equipment

Baghdad lithium battery pack equipment

-

What is the mc mark on the front of the lithium battery pack

What is the mc mark on the front of the lithium battery pack

-

What do you need to build a lithium battery pack

What do you need to build a lithium battery pack

-

San Salvador lithium battery pack equipment

San Salvador lithium battery pack equipment

-

What nickel sheet is used in lithium battery pack

What nickel sheet is used in lithium battery pack

-

48v lithium battery pack factory

48v lithium battery pack factory

-

Paris lithium battery pack

Paris lithium battery pack

-

Costa Rica Power Lithium Battery Pack

Costa Rica Power Lithium Battery Pack

-

Lithium battery pack converted into mobile power supply

Lithium battery pack converted into mobile power supply

Commercial & Industrial Solar Storage Market Growth

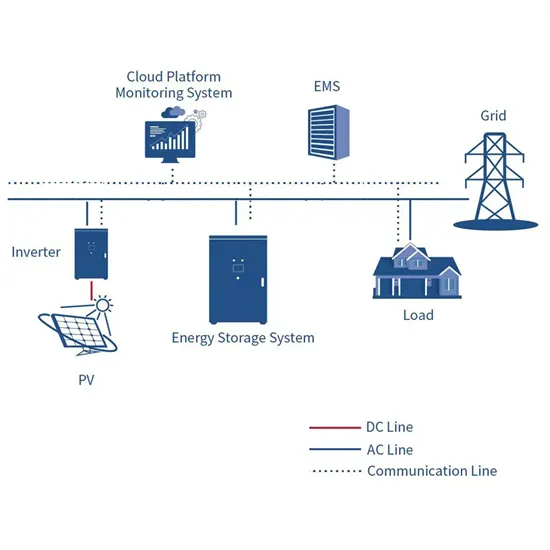

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.