The Best Custom Designed EV Battery Insulation

Dec 20, 2024 · In this post, we''ll explore some of the best custom-engineered materials for EV battery insulation and shock absorption, and why they are

Get Started

LITHIUM BATTERY PACK DETAILS

Introduction What is a lithium battery pack? Battery pack generally refers to the com battery, which mainly refers to the processing and assembly of lithium

Get Started

Assembling and Testing Lithium-ion Battery

Jan 25, 2025 · Assembling a lithium-ion battery pack is a meticulous process that requires careful planning and precise execution. It involves several critical

Get Started

Thermal shock protection with scalable heat-absorbing

Aug 20, 2024 · The authors report a cost-effective and scalable approach encapsulating phase change materials into micron-porous aerogels to realize phase change materials with

Get Started

Against shock lithium battery pack box body

The invention discloses a kind of against shock lithium battery pack box bodies,Including outer case,The outer case side is hinged with case lid by hinge,Internal box is equipped in the outer

Get Started

Battery Pack Liquid Absorbers

Battery packs are the core elements of mobile and stationary lithium-ion energy storage systems. They are used in automotive and industrial applications. The

Get Started

Effect of Vibration on Lithium Battery

Jun 11, 2025 · Protective casings combined with advanced shock absorption technologies significantly enhance the durability of lithium-ion battery packs.

Get Started

Cell geometry influences on the vibration performance of lithium

Feb 15, 2025 · The battery packs may experience resonance frequencies because of random vibrations experienced during EV operations, which can result in internal short circuits in the

Get Started

New Energy Battery Shock Absorption Package

Battery pack shock absorption method The invention relates to the technical field of battery devices and discloses a storage battery pack with a damping function.

Get Started

Lithium battery box with passive shock absorption auxiliary

An auxiliary support, lithium battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of personal safety and property safety, high

Get Started

Battery Pads & Cushions

Battery Compression Pads and Cushions Battery Pad cushions, or compression pads, used inside an EV pouch cell battery pack must be firm enough to hold components in place and

Get Started

CN118712605A

The present invention relates to the technical field of anti-collision and shock absorbing devices for battery packs, and discloses an anti-collision and shock absorbing device for battery packs

Get Started

A lithium battery shock absorb box

A lithium battery and box door technology, which is applied to lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of lithium battery damage,

Get Started

CN215476524U

The utility model discloses a damping box for a lithium storage battery pack, which comprises a box body and a battery pack, wherein the box body mainly comprises a box shell, a supporting

Get Started

Effective Mechanical Properties of an Innovative Module

Jun 24, 2024 · To create advanced lithium-ion battery packs (BP) that are both lightweight and durable in crashes, an innovative honeycomb BP design has been developed. This design

Get Started

Consistency evaluation of Lithium-ion battery packs in

Dec 20, 2024 · The battery pack inconsistency is affected by factors such as battery capacity, internal resistance, and self-discharge rate during use, resulting in differences in aging and

Get Started

Lithium battery shock absorption requirements

Are lithium-ion batteries safe? The frequent safety accidents involving lithium-ion batteries (LIBs) have aroused widespread concern around the world. The safety standards of LIBs are of great

Get Started

Mechanical issues of lithium-ion batteries in road traffic

Aug 1, 2024 · According to road conditions and traffic accident data, we categorize the potential loads on vehicular lithium-ion power batteries into three main types: vibration, mechanical

Get Started

Lithium battery pack insulation and shock-resistant materials

Insulating plate for battery, lithium ion battery, and battery pack to prevent short circuits, improve safety, and prevent explosions. The insulating plate has a two-layer

Get Started

Safety-enhanced battery modules with actively switchable

Nov 15, 2024 · Multifunctionality is achieved by a magnetic field that instantly changes the viscosity of MSTF. In this paper, a magnetically controlled multifunctional smart material

Get Started

What are the effects of shock and vibration on battery packs?

Jun 13, 2024 · Battery packaging should be designed to consider the effects of vibration and shock, and appropriate measures should be taken to protect the battery''s internal structure.

Get Started

VIBRATION ISOLATION OF LITHIUM BATTERIES

Jul 27, 2022 · Recent studies investigated the effect of vibrations on the degradation and fatigue of battery cell materials as well as the effect of

Get Started

Materials for EV Battery Electrical Insulation

Aug 1, 2025 · Discover innovations in insulation materials for EV battery cells, designed to prevent short circuits and enhance safety and performance.

Get Started

Materials for EV Battery Insulation and Shock Absorption

Mar 31, 2025 · While manufacturers use many different types of adhesives to bond the internal components within EV batteries, insulating materials offer the additional benefit of regulating

Get Started

What are the effects of shock and vibration on battery packs?

Jun 13, 2024 · Several aspects of vibration and shock affect lithium batteries: Loss of capacity: Prolonged or substantial vibration and shock may cause spalling or damage to the active

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · This project offers a detailed overview of the process involved in designing a mechanical structure for an electric vehicle''s 18 kWh battery pack.

Get Started

A review of lithium-ion battery safety concerns: The issues,

Aug 1, 2021 · Efficient and reliable energy storage systems are crucial for our modern society. Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics

Get Started

Effects of vibrations and shocks on lithium-ion cells

Aug 15, 2015 · Abstract Lithium-ion batteries are increasingly used in mobile applications where mechanical vibrations and shocks are a constant companion. This work shows how these

Get Started

Review of Lithium-Ion Battery Internal Changes

Jul 22, 2024 · The growth of electric vehicles (EVs) has prompted the need to enhance the technology of lithium-ion batteries (LIBs) in order to improve their

Get Started

CN214987422U

The utility model relates to the technical field of lithium battery packs, in particular to a lithium battery pack with a shock-absorbing protective shell, which comprises a bottom plate, wherein

Get Started

Waterproof shock-absorption material used for battery pack

A technology of new energy vehicles and shock-absorbing materials, applied in the field of materials, can solve problems such as uncontrollable combustion of lithium batteries, difficulty

Get Started

Shock absorption type lithium battery protection plate based

A battery protection plate, elastic limit technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems of adjusting the shock absorption effect,

Get Started

New Energy Battery Shock Absorption Package

Structural Analysis of Battery Pack Box for New Energy Vehicles The box structure of the power battery pack is an important issue to ensure the safe driving of new energy vehicles,

Get Started

Battery Pack Liquid Absorbers make batteries

The absorbent pads capture and reliably store unwanted liquids. With adjustable absorption capacity and custom geometries, Battery Pack Liquid Absorbers

Get Started

Lithium battery with shock absorption and heat dissipation

A technology of heat dissipation structure and lithium battery, which is applied to secondary batteries, structural parts, battery pack components, etc., can solve the problems of reduced

Get Started

6 FAQs about [Lithium battery pack internal shock absorption]

Can a module-free lithium-ion battery improve EV crashworthiness?

To enhance energy density, reduce weight, and improve crashworthiness of traditional lithium-ion batteries in EVs, a novel module-free battery pack is suggested. This design integrates a module to a cell, forming a cylindrical lithium-ion battery within a honeycomb structure.

What is a battery pack?

A battery pack is the final form of the battery system in an electric vehicle (EV), made by combining modules with cooling, control, and protection systems. The largest weight component in an EV is the battery pack at the current state of EV technology.

Do EV batteries need insulating materials?

While manufacturers use many different types of adhesives to bond the internal components within EV batteries, insulating materials offer the additional benefit of regulating their internal temperature. These practical examples should give you an idea of insulation and shock absorption materials to consider.

Are cylindrical Li-ion batteries exposed to direct crash loads?

The cylindrical Li-ion batteries are not exposed to direct crash loads as they are enclosed in a box-like pack structure, which is securely attached to the car body through robust reinforcing frame structures. Therefore, it is reasonable to assume that only small elastic deformations can occur.

How to reduce the weight of lithium ion batteries in a honeycomb cell?

This design involves inserting cylindrical lithium-ion battery cells into a honeycomb cell core, eliminating the need for traditional modules. To reduce the weight of BP, collision analyses using the finite element method (FEM) are conducted with various thickness-to-length ratios for the honeycomb cell structures.

Why do EV batteries need thermal insulation?

EV battery thermal insulation controls the internal flow of heat to avoid short circuits and protects the individual components within the battery pack from damage caused by rough movement, a.k.a. collisions. Minor scrapes on an EV battery can eventually lead to thermal runaway propagation.

Related Articles

-

UPS lithium battery pack internal structure

UPS lithium battery pack internal structure

-

Assemble 12v lithium battery pack

Assemble 12v lithium battery pack

-

New Zealand Auckland RV lithium battery pack

New Zealand Auckland RV lithium battery pack

-

Which Paraguayan lithium iron phosphate battery pack decays faster

Which Paraguayan lithium iron phosphate battery pack decays faster

-

Assembly of lithium titanate battery pack

Assembly of lithium titanate battery pack

-

Kinshasa forklift lithium battery pack wholesale

Kinshasa forklift lithium battery pack wholesale

-

Middle East Communication Base Station Lithium Battery Pack

Middle East Communication Base Station Lithium Battery Pack

-

How much does it cost to produce a lithium battery pack

How much does it cost to produce a lithium battery pack

-

How many volts does a four-cell lithium battery pack have

How many volts does a four-cell lithium battery pack have

-

Lithium Battery 16 8V Battery Pack

Lithium Battery 16 8V Battery Pack

Commercial & Industrial Solar Storage Market Growth

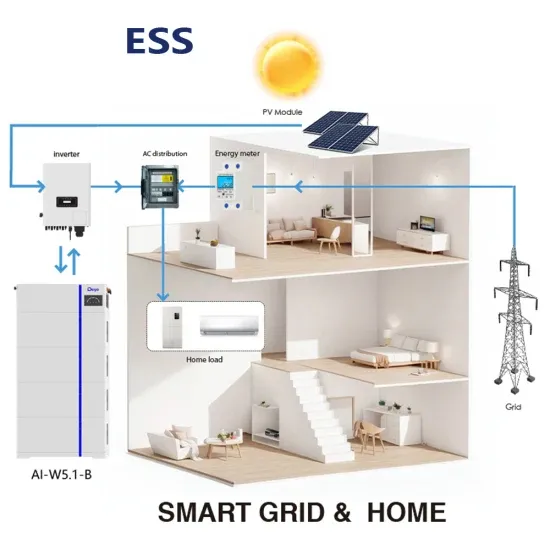

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.