Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

Get Started

Flywheel energy storage

Jan 1, 2023 · As one of the interesting yet promising technologies under the category of mechanical energy storage systems, this chapter presents a comprehensive introduction and

Get Started

Distributed control of a flywheel energy storage system

Nov 1, 2022 · This paper considers a distributed control problem for a flywheel energy storage system consisting of multiple flywheels subject to unreliable communication network. There

Get Started

Flywheel Energy Storage

Aug 12, 2025 · The working principle of flywheel energy storage: under the condition of surplus power, the flywheel is driven by electric energy to rotate at

Get Started

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · A review of the recent development in flywheel energy storage technologies, both in academia and industry.

Get Started

JY Flywheel

Guangdong Jiyang Energy Technology Co., Ltd. is a leading provider of green, energy-saving energy storagesolutions. Driven by our mission to facilitate energy transition and promote

Get Started

Flywheel Energy Storage (FES) Systems

Oct 26, 2023 · Explore the intriguing world of Flywheel Energy Storage (FES) systems, their working principles, benefits, applications, and future prospects.

Get Started

The High-speed Flywheel Energy Storage System

Sep 25, 2018 · A flywheel energy storage system converts electrical energy supplied from DC or three-phase AC power source into kinetic energy of a spinning mass or converts kinetic

Get Started

Flywheel energy storage principle and research status

How does a flywheel energy storage system work? Based on the aforementioned research,this paper proposes a novel electric suspension flywheel energy storage system equipped with

Get Started

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheel storage energy system is not a new technology; however, the deep interest in applying its principle in power system applications has been greatly increasing in

Get Started

(PDF) Energy Storage in Flywheels: An Overview

May 1, 2015 · This paper presents an overview of the flywheel as a promising energy storage element. Electrical machines used with flywheels are surveyed

Get Started

Technical Evolution of Advanced Flywheel Energy Storage

Jul 30, 2019 · Its operation principle, and five key technologies including the flywheel rotor, bearing system, energy conversion aspect, motor/generator and vacuum chamber are

Get Started

Modeling and Control of Flywheel Energy Storage System

May 15, 2023 · Flywheel energy storage has the advantages of fast response speed and high energy storage density, and long service life, etc, therefore it has broad applicatio

Get Started

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

Get Started

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · 00-01 99-00 Keywords: and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There

Get Started

A Review of Flywheel Energy Storage System

A description of the flywheel structure and its main components is provided, and different types of electric machines, power electronics converter topologies,

Get Started

Design and Research of a New Type of Flywheel Energy Storage

Feb 18, 2025 · This article proposes a novel flywheel energy storage system incorporating permanent magnets, an electric motor, and a zero-flux coil. The permanent magnet is utilized

Get Started

A review of control strategies for flywheel energy storage

Nov 1, 2022 · The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

Get Started

Comprehensive review of energy storage systems

Jul 1, 2024 · Battery, flywheel energy storage, super capacitor, and superconducting magnetic energy storage are technically feasible for use in distribution networks. With an energy density

Get Started

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · The US Marine Corps are researching the integration of flywheel energy storage systems to supply power to their base stations through renewable energy sources. This will

Get Started

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

Get Started

eriyabv

A review of energy storage types, applications and recent developments. S. Koohi-Fayegh, M.A. Rosen, in Journal of Energy Storage, 2020 2.4 Flywheel energy storage. Flywheel energy

Get Started

Development and prospect of flywheel energy storage

Oct 1, 2023 · Its working principle is based on the use of electricity as the driving force to drive the flywheel to rotate at a high speed and store electrical energy in the form of mechanical energy.

Get Started

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Supported by illustrated circuits, the paper describes the major role of each part of the FES system in the improvement of the power quality of the network. Then it discusses a

Get Started

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Get Started

Flywheel energy storage principle video tutorial

This document describes a flywheel energy storage system. It includes an introduction, block diagram, theory of operation, design, components, circuit diagram, advantages and

Get Started

Design and prototyping of a new flywheel

Sep 5, 2017 · This study presents a new ''cascaded flywheel energy storage system'' topology. The principles of the proposed structure are presented.

Get Started

What are the benefits of flywheel energy storage power

The objective of this paper is to describe the key factors of flywheel energy storage technology, and summarize its applications including International Space Station (ISS), Low Earth Orbits

Get Started

Principles and application scenarios of flywheel

Aug 19, 2025 · Flywheel energy storage is a high-power, fast-response, high-frequency, long-life mechanical energy storage technology with broad

Get Started

Modeling and Control of Flywheel Energy Storage System

May 15, 2023 · Flywheel energy storage has the advantages of fast response speed and high energy storage density, and long service life, etc, therefore it has broad application prospects

Get Started

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electrical power system into one that is fully sustainable yet low

Get Started

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store

Get Started

A Review of Flywheel Energy Storage System

Sep 7, 2023 · The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind

Get Started

6 FAQs about [Principle of expansion of flywheel energy storage transformer for communication base stations]

Is flywheel storage energy system a new technology?

Flywheel storage energy system is not a new technology; however, the deep interest in applying its principle in power system applications has been greatly increasing in the recent decades.

Is a flywheel energy storage system based on a permanent magnet synchronous motor?

In this paper, a grid-connected operation structure of flywheel energy storage system (FESS) based on permanent magnet synchronous motor (PMSM) is designed, and the mathematical model of the system is established.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research , studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

How does a flywheel energy unit work?

D. Power Electronics The flywheel energy unit produces variable frequency AC current. To reliably operate the system, power electronics devices must be installed in order to keep the frequency constant so that it can be connected to the grid. Power converters for energy storage systems are based on SCR, GTO or IGBT switches.

What is a flywheel energy storage system (fess)?

According to Al-Diab (2011) the flywheel energy storage system (FESS) could be exploited beneficially in dealing with many technical issues that appear regularly in distribution grids such as voltage support, grid frequency support, power quality improvement and unbalanced load compensation.

Related Articles

-

How important is flywheel energy storage in communication base stations

How important is flywheel energy storage in communication base stations

-

African companies producing flywheel energy storage for communication base stations

African companies producing flywheel energy storage for communication base stations

-

How much does flywheel energy storage wind power generation cost for communication base stations

How much does flywheel energy storage wind power generation cost for communication base stations

-

Flywheel energy storage for communication base stations and flywheel energy storage for communication base stations

Flywheel energy storage for communication base stations and flywheel energy storage for communication base stations

-

Flywheel energy storage for communication base stations

Flywheel energy storage for communication base stations

-

Main components of flywheel energy storage in communication base stations

Main components of flywheel energy storage in communication base stations

-

Contract for construction of flywheel energy storage for communication base stations

Contract for construction of flywheel energy storage for communication base stations

-

The country has expanded and upgraded the flywheel energy storage capacity of communication base stations

The country has expanded and upgraded the flywheel energy storage capacity of communication base stations

-

Madagascar 5G communication base station flywheel energy storage construction project

Madagascar 5G communication base station flywheel energy storage construction project

-

What is the communication base station flywheel energy storage to optical exchange

What is the communication base station flywheel energy storage to optical exchange

Commercial & Industrial Solar Storage Market Growth

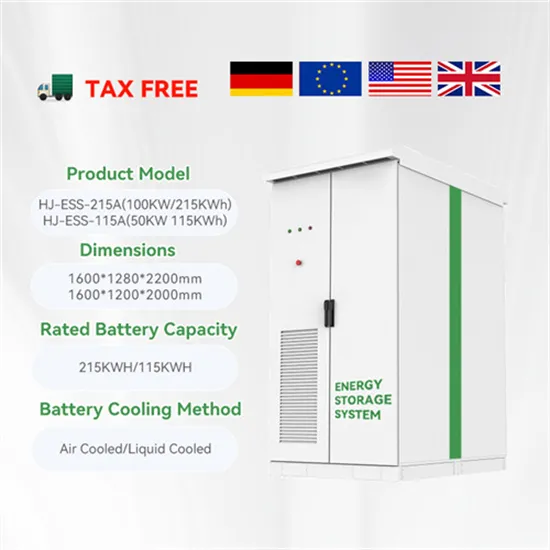

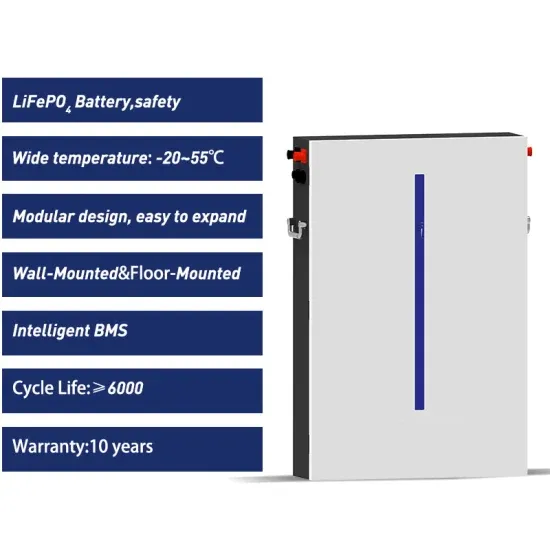

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.