Could Flywheels Be the Future of Energy

Jul 7, 2023 · Flywheels are one of the world''s oldest forms of energy storage, but they could also be the future. This article examines flywheel technology, its

Get Started

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens

Get Started

Flywheel energy storage

Jan 1, 2023 · The main part, let''s say the heart, of a FESS is the rotating disk (called the flywheel), of which there are many examples of applications today that could help us

Get Started

Flywheel energy storage

Jan 1, 2023 · The disk (flywheel) is the main component of a FESS setup. However, energy cannot be stored and returned to the system at acceptable efficiency without several other

Get Started

Flywheels

Jan 1, 2016 · These systems are deployed in applications as diverse as uninterruptible power supplies, gantry cranes, and large research facilities. The chapter presents the technical

Get Started

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

Get Started

FESS Fkywheel Energy Storage Systems

Jun 26, 2025 · UPS Uninterrupted Power Supply - Emergency back-up power - Global data centers, communication base stations, and important activities all

Get Started

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

Get Started

What is a flywheel energy storage? | NenPower

Mar 6, 2024 · The exploration and understanding of flywheel energy storage technology reveal its immense potential in diversifying energy storage options

Get Started

Site Energy Revolution: How Solar Energy

Nov 13, 2024 · Discover how solar energy is reshaping communication base stations by reducing energy costs, improving reliability, and boosting

Get Started

Energy-efficiency schemes for base stations in 5G

In today''s 5G era, the energy efficiency (EE) of cellular base stations is crucial for sustainable communication. Recognizing this, Mobile Network Operators are actively prioritizing EE for

Get Started

Principles and application scenarios of flywheel

Aug 19, 2025 · Principles and application scenarios of flywheel energy storage Flywheel energy storage technology is an emerging energy storage

Get Started

Optimization of Renewable Energy Integrated Electric

Jun 29, 2024 · Keywords: Renewable energy, electric vehicle charging infrastructure, flywheel energy storage, optimization, power management, hybrid solar-wind system, AI-assisted control.

Get Started

Flywheel energy storage systems: A critical

Jul 19, 2021 · Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

Get Started

grid connection procedures for flywheel energy storage power stations

A Control Algorithm for Electric Vehicle Fast Charging Stations Equipped With Flywheel Energy Storage This paper proposes a control strategy for plug-in electric vehicle (PEV) fast charging

Get Started

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Get Started

Resource management in cellular base stations powered by

Jun 15, 2018 · This paper aims to consolidate the work carried out in making base station (BS) green and energy efficient by integrating renewable energy sources (RES). Clean and green

Get Started

Flywheel Energy Storage: The Key To Sustainable

Oct 16, 2024 · Flywheel energy storage is a promising technology that can provide fast response times to changes in power demand, with longer lifespan

Get Started

Flywheel energy storage systems: A critical

Jul 19, 2021 · In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components,

Get Started

Modeling flywheel energy storage system

May 29, 2020 · Abstract and Figures Energy storage technologies are of great practical importance in electrical grids where renewable energy sources are

Get Started

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Get Started

A novel capacity configuration method of flywheel energy storage

Jun 1, 2021 · This paper proposes a capacity configuration method of the flywheel energy storage system (FESS) in fast charging station (FCS). Firstly, the load current compensation and

Get Started

Modeling and aggregated control of large-scale 5G base stations

Mar 1, 2024 · A significant number of 5G base stations (gNBs) and their backup energy storage systems (BESSs) are redundantly configured, possessing surplus capacit

Get Started

Structure and components of flywheel energy

Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel energy storage system (FESS). Although

Get Started

Flywheel energy and power storage systems

Feb 1, 2007 · During that time several shapes and designs where implemented, but it took until the early 20th century before flywheel rotor shapes and rotational stress were thoroughly

Get Started

Flywheels | Climate Technology Centre

Aug 18, 2025 · Components of a flywheel energy storage system A flywheel has several critical components. a) Rotor – a spinning mass that stores energy in

Get Started

Components of Flywheel Energy Storage System.

The components of flywheel energy storage system are depicted in Figure 1. Multiple flywheels may be connected together to provide various megawatt

Get Started

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel

Get Started

6 FAQs about [Main components of flywheel energy storage in communication base stations]

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

Can flywheels be used for power storage systems?

Flywheels are now a possible technology for power storage systems for fixed or mobile installations. FESS have numerous advantages, such as high power density, high energy density, no capacity degradation, ease of measurement of state of charge, don’t require periodic maintenance and have short recharge times .

What is a flywheel & how does it work?

Flywheels with the main attributes of high energy efficiency, and high power and energy density, compete with other storage technologies in electrical energy storage applications, as well as in transportation, military services, and space satellites .

What is a flywheel energy storage system (fess)?

One energy storage technology now arousing great interest is the flywheel energy storage systems (FESS), since this technology can offer many advantages as an energy storage solution over the alternatives.

Can flywheel energy storage system improve frequency regulation?

Inertia emulation by flywheel energy storage system for improved frequency regulation. In 2018 IEEE 4th southern power electronics conference (SPEC) (pp. 1–8). IEEE. A review of control strategies for flywheel energy storage system and a case study with matrix converter Zhou, Y., Li, Y., Lv, Q., Lv, D., Yang, Y., & Zheng, J. (2020).

How do flywheels work in train energy recovery systems?

In train energy recovery systems, flywheels are installed at stations or substations to recover energy through regenerative braking, and supply it back into the system for traction purposes. Flywheels are well suited for this application due to the high rate of charge-discharge cycles needed.

Related Articles

-

Contract for construction of flywheel energy storage for communication base stations

Contract for construction of flywheel energy storage for communication base stations

-

Is the investment in flywheel energy storage for communication base stations reliable

Is the investment in flywheel energy storage for communication base stations reliable

-

African companies producing flywheel energy storage for communication base stations

African companies producing flywheel energy storage for communication base stations

-

Flywheel energy storage for communication base stations and flywheel energy storage for communication base stations

Flywheel energy storage for communication base stations and flywheel energy storage for communication base stations

-

Maintenance plan for flywheel energy storage in communication base stations

Maintenance plan for flywheel energy storage in communication base stations

-

What are the sub-projects of flywheel energy storage in communication base stations

What are the sub-projects of flywheel energy storage in communication base stations

-

The country has expanded and upgraded the flywheel energy storage capacity of communication base stations

The country has expanded and upgraded the flywheel energy storage capacity of communication base stations

-

Principle of expansion of flywheel energy storage transformer for communication base stations

Principle of expansion of flywheel energy storage transformer for communication base stations

-

Flywheel energy storage for communication base stations

Flywheel energy storage for communication base stations

-

Communication base station flywheel energy storage cabinet protection box manufacturer

Communication base station flywheel energy storage cabinet protection box manufacturer

Commercial & Industrial Solar Storage Market Growth

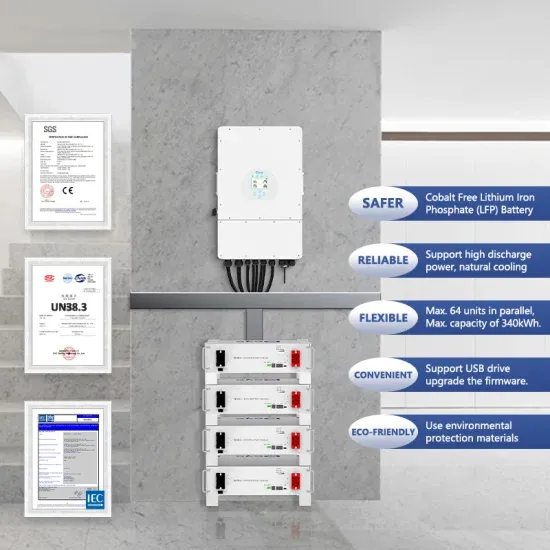

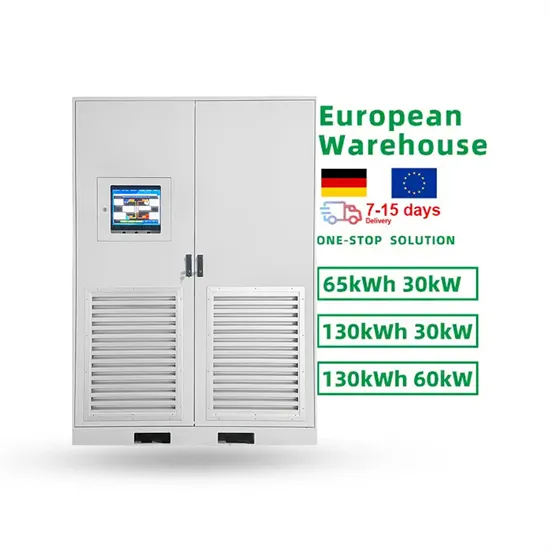

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.