How Are Lithium-Ion Batteries Manufactured

Jun 22, 2025 · Inside a lithium-ion battery, you can find a mix of metals and other materials working together. The main ingredients include nickel, manganese,

Get Started

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Battery cell assembly is one of the key steps in the lithium battery module PACK production line. First, the battery cells are combined with

Get Started

Here are the 4 Top Considerations in Lithium-Ion

Sep 6, 2021 · Lithium-ion battery manufacturing demands the most stringent humidity control and the first challenge is to create and maintain these ultra

Get Started

Revolutionizing Energy Storage: Inside a 12V Lithium-ion Battery Factory

Feb 14, 2025 · When you step inside a 12V lithium-ion battery factory, the first thing that strikes you is the scale of operations. These facilities are massive, housing state-of-the-art equipment

Get Started

The Battery Cell Factory of the Future | BCG

Jan 30, 2025 · 1. Structure Optimizing factory layouts and battery-specific infrastructure can significantly reduce operational costs and the physical

Get Started

How are batteries made in a Gigafactory?

Jun 14, 2022 · It is expected that, by 2030, between 35 and 40 Gigafactories will be needed to supply the battery demand of the automotive sector in Europe.

Get Started

Inside Li-ion Battery Production: From Raw

Mar 23, 2025 · Explore 2025''s lithium-ion battery production breakthroughs—from dry electrode processing to solid-state prototypes—and learn how Vade

Get Started

South Korea: Exploding lithium batteries spark

Jun 24, 2024 · A massive factory fire that began after several lithium batteries exploded has killed at least 22 people in South Korea.

Get Started

An Inside Look at Lathrop Megafactory Where

Apr 29, 2025 · It''s essentially a large-scale, rechargeable lithium-ion battery system designed for utility-scale energy storage, capable of storing over 3.9

Get Started

March 2022 Lithium-ion battery manufacturing plants –

May 24, 2022 · battery plants – insurance The huge global demand for mobile devices, electric vehicles, and all kinds of technological gadgets, has led to a growing need for lithium-ion

Get Started

What is inside a Lithium-Ion Battery?

Apr 30, 2025 · In this guide, we''ll break down the inner workings of a lithium-ion battery, exploring the key components, and how they function to power our

Get Started

Inside the Production: Where Are Tesla Batteries

Dec 25, 2024 · Tesla has redefined the automotive industry by popularizing electric vehicles (EVs) and setting new standards for battery technology. Its

Get Started

Blaze at South Korea lithium battery plant kills

Jun 25, 2024 · A lithium battery factory in South Korea was set on fire after multiple batteries exploded on Monday, killing 22 workers, most of them

Get Started

Facilities of a lithium-ion battery production plant

May 3, 2018 · This Chapter describes the set-up of a battery production plant. The required manufacturing environment (clean/dry rooms), media supply,

Get Started

At least 22 dead after South Korea lithium battery factory fire

Jun 24, 2024 · At least 22 people have died after a large fire tore through a lithium battery manufacturing factory near South Korea ''s capital on Monday.

Get Started

Smoke from fire at California lithium battery

Jan 18, 2025 · A fire at the world''s largest battery storage plant in Northern California is smoldering after sending plumes of toxic smoke into the atmosphere.

Get Started

Inside a Modern Battery Factory: How Cutting

Sep 28, 2024 · Modern battery factories are at the forefront of this revolution, employing cutting-edge technologies to enhance production efficiency,

Get Started

Inside a Modern Battery Factory: How Cutting

Sep 28, 2024 · The development of new materials and chemical technologies is pivotal to enhancing battery performance. Development of New Battery

Get Started

Revolutionizing the Battery Industry: Inside a Lithium-Titanate Battery

Inside a lithium-titanate battery factory, the production process begins with the careful selection and preparation of raw materials. High-quality lithium compounds and titanium dioxide are

Get Started

LFP Batteries Revolutionized Chinese EVs. Now,

The facility is an expansion of its existing battery factory that already produces lithium-ion batteries for General Motors, Honda and Hyundai.

Get Started

Lithium-Ion Battery Storage Factory

1 day ago · Eco-Friendliness – Unlike traditional batteries, Li-ion systems have a lower environmental impact when recycled properly. Voltsmile''s factory is

Get Started

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion batteries use lithium in ionic form instead of in solid metallic form and are usually rechargeable, often without needing to remove the battery from the device. They

Get Started

India''s 7 Largest Lithium-Ion Battery Gigafactories

Aug 26, 2024 · This is the first Giga factory for Lithium-Ion batteries in the Gujrat state. The significant investment made by the Tata Group in the Gujarat lithium-ion battery plant

Get Started

Video Shows Batteries Exploding, Sparking Deadly Blaze in

Jun. 25—SEOUL( The Korea Herald/ANN) — A fire that broke out at a lithium-ion battery factory in Hwaseong, Gyeonggi Province, has left at least 22 workers dead, eight injured and one missing

Get Started

Inside the gigafactory producing the world''s greenest batteries

Jul 1, 2023 · When complete in about 2026, Northvolt Ett will employ 4000 people and produce 60 gigawatt-hours of lithium battery cells a year, enough for a million medium-sized electric cars.

Get Started

Inside A Gigafactory: What Goes On in Battery

6 days ago · With the growing global demand for EVs requiring more lithium-ion batteries – and the scarcity of lithium – future-focused gigafactories are

Get Started

Despite the fire hazards of lithium-ion: Battery

Nov 18, 2021 · In May 202 3, a 20,000 pound lithium-ion battery inside caught fire inside a battery factory in Jacksonville, FL on April 25th. HazMat crews

Get Started

Breaking Down the Components of a Lithium-Ion Battery

May 8, 2025 · Lithium-ion batteries power modern technologies by combining advanced components to ensure efficient energy storage and delivery. Inside a lithium battery, the

Get Started

What''s Inside A Lithium-Ion Battery? | Lithium

May 21, 2021 · Inside a lithium-ion battery, you''ll find lithium-ion cells which have electrodes & electrolyte inside them. Learn more about what''s inside.

Get Started

Fire at Lithium Battery Plant in South Korea Kills 22

Jun 24, 2024 · A fire at a lithium battery factory near Seoul on Monday killed 22 workers, most of them migrant laborers from China, in one of the deadliest

Get Started

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Get Started

6 FAQs about [Inside a large lithium battery factory]

How are lithium ion battery cells manufactured?

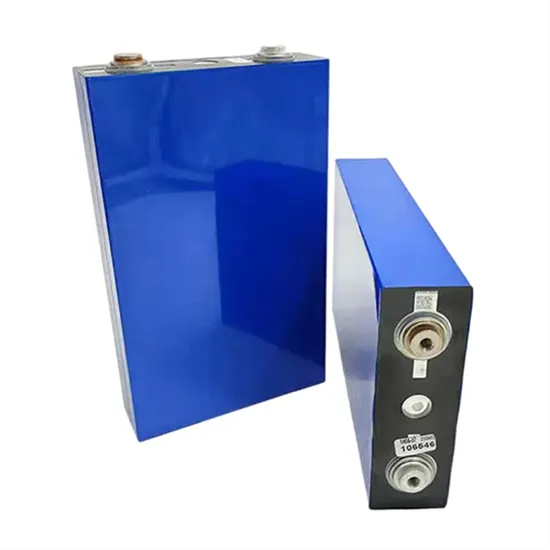

The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode manufacturing and cell finishing process steps are largely independent of the cell type, while cell assembly distinguishes between pouch and cylindrical cells as well as prismatic cells.

What is a lithium-ion battery Gigafactory?

To ramp up EV adoption and manufacturing, we need more lithium-ion batteries – and that's where lithium-ion battery gigafactories come into play. A gigafactory is where products and components are manufactured for industries moving toward electrification and a lower carbon footprint.

How does automation affect lithium-ion battery production?

Automation now shapes how lithium-ion batteries are made in modern factories. Robots handle electrode production, cell assembly, and battery pack building. This reduces human error and increases output. Some factories run 24/7 with no human supervision, boosting efficiency and lowering risks.

How does a lithium ion battery come to life?

A Lithium-ion battery comes to life through a multi-stage, precise process. Start with raw materials that become carefully engineered layers inside each cell. These layers include the cathode, anode, separator, and electrolyte.

What is lithium ion battery manufacturing?

Lithium-ion battery manufacturing now relies on both science and technology for consistency and performance. Lithium-ion batteries are made from key materials like lithium, nickel, cobalt, manganese, copper, aluminum, and graphite, each playing a vital role in battery performance and cost.

How a lithium battery is made?

The lithium battery manufacturing process starts by making a thick paste called slurry. This step is important because it sets the stage for the rest of the process. Active materials, binders, and solvents are mixed. The active materials can be lithium compounds for the cathode or graphite for the anode.

Related Articles

-

Outdoor lithium battery 12v large capacity with inverter

Outdoor lithium battery 12v large capacity with inverter

-

Large cylindrical 10ah lithium battery

Large cylindrical 10ah lithium battery

-

No 9 large capacity lithium battery pack

No 9 large capacity lithium battery pack

-

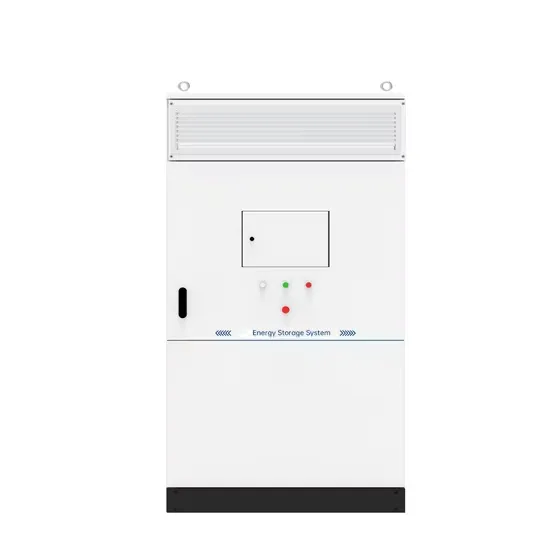

Uruguay lithium battery station cabinet factory 125kWh

Uruguay lithium battery station cabinet factory 125kWh

-

Magadan large energy storage lithium battery

Magadan large energy storage lithium battery

-

Macedonia 24v lithium battery pack factory

Macedonia 24v lithium battery pack factory

-

Kingston New Energy Lithium Battery Factory

Kingston New Energy Lithium Battery Factory

-

48v lithium battery pack factory

48v lithium battery pack factory

-

Hungarian large capacity lithium battery pack

Hungarian large capacity lithium battery pack

-

How much does a lithium battery pack factory cost

How much does a lithium battery pack factory cost

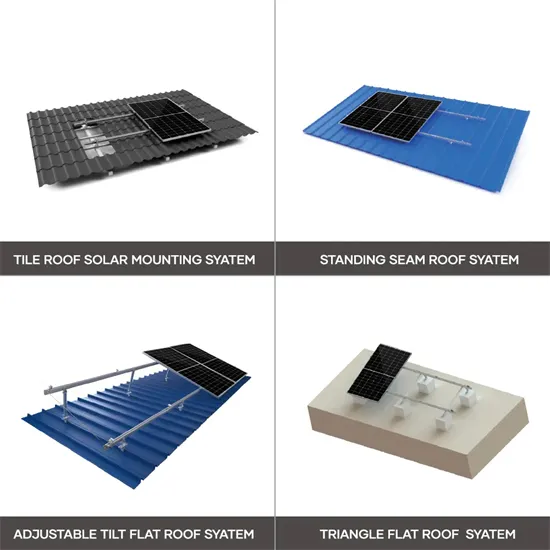

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

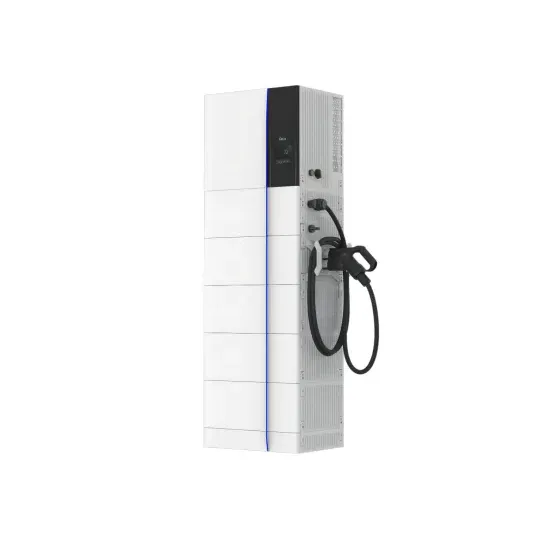

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.