【A-NH】DC 12V TO AC 220V 380V 500W 1000W Inverter

1. High energy efficiency,, low power consumption, convenient and safe to use, energy saving and, widely used in, night camps, night market vendors, driving and family power outage

Get Started

Photovoltaic microinverter using single-stage isolated high-frequency

Abstract In this paper, PhotoVoltaic (PV) microinverter using a single-stage high-frequency ac link series resonant topology is proposed. The inverter has two active bridges, one at the front-end

Get Started

Optimal design of high frequency high efficiency

Aug 10, 2022 · Due to the development of high-speed rail towards high efficiency and light weight, the volume and efficiency of the power module are assessed,

Get Started

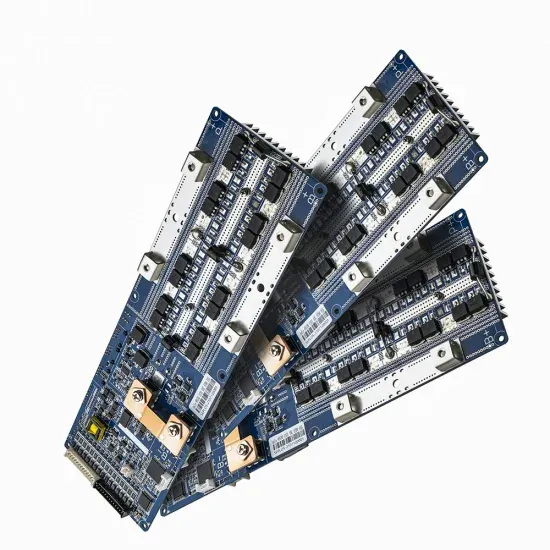

Understanding the Inverter Power Stage Module: Converting High

Aug 6, 2025 · Inverter power stage modules play a crucial role in converting high-voltage direct current (DC) to three-phase alternating current (AC). To efficiently manage this operation, a

Get Started

New 600V GaN Single-Stage Isolated Bidirectional 400V

Nov 7, 2023 · I. INTRODUCTION Traditionally, isolated three-phase power-factor-correction (PFC) rectifiers generating a 400 V dc bus voltage from the European 400 V three-phase

Get Started

High-Frequency Inverters: From Photovoltaic, Wind, and Fuel

Jan 1, 2011 · In such an approach, a HF transformer (instead of a line-frequency transformer) is used for galvanic isolation and voltage scaling, resulting in a compact and low-footprint design.

Get Started

Active Front End (AFE)

Jan 24, 2024 · In particular, when first connecting an Active Front End to the grid, a proper DC bus precharge mechanism is required to avoid potentially

Get Started

A High Frequency Isolated DC-AC Converter using Dual

Mar 27, 2021 · This paper proposes a new high-frequency isolated PV inverter topology which combines the aforementioned ad- vantages of conventional high-frequency link and two-stage

Get Started

Impedance characteristics investigation and oscillation

Aug 1, 2022 · In order to obtain impedance characteristics of the photovoltaic (PV) inverter and reveal potential stability issues of the PV inverter connected to a weak grid, a complete

Get Started

Modular Solution Simplifies Design Of PFC Front End For

Jan 15, 2014 · The design of the module, which is built on an insulated metal substrate (IMS), is highly flexible and can accommodate either a high-frequency PFC stage, (high-frequency

Get Started

Three-mode one-cycle controlled current-source single-stage

Sep 13, 2022 · A current-source single-stage multi-input high-frequency-link grid-connected inverter and a three-mode one-cycle control strategy are proposed and deeply investigated in

Get Started

11-kW, Bidirectional, Three-Phase ANPC Based on GaN

May 11, 2022 · This reference design provides a design template for implementing a three-level, three-phase, gallium nitride (GaN) based ANPC inverter power stage. The use of fast

Get Started

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · A CIB IGBT module has a diode based three phase rectifier front end, IGBT based three-phase inverter output stage and a brake chopper stage all integrated within a single

Get Started

3-Level GaN Inverters for Highly Efficient Power Electronics

Feb 14, 2025 · Multi-level inverters, especially 3-level configurations, are becoming crucial in electric vehicle drivetrains for their efficiency and capability to handle high voltage levels. Hofer

Get Started

High-Efficiency Inverter for Photovoltaic Applications

Dec 4, 2023 · Abstract—We introduce a circuit topology and associated con-trol method suitable for high efficiency DC to AC grid-tied power conversion. This approach is well matched to the

Get Started

STEVAL-ISV002V1, STEVAL-ISV002V2 3 kW grid

This application note describes the development and evaluation of a conversion system for PV applications with the target of achieving a significant reduction in production costs and high

Get Started

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · This application report documents the concept reference design for the DC-DC Stage and the DC-AC Converter section that can be used in the High-Frequency Inverter

Get Started

high-power inverter based hybrid switch SiC+IGBT

Mar 19, 2024 · Hybrid switch configuration considfred is 1:4 ratio (1 SiC + 3 IGBTs) Efficiency gain of full SiC Inverter and hybrid switch inverters vs IGBT inverter is from low load to medium

Get Started

The current status and development of DC/AC

Apr 14, 2023 · Future trends in inverters at this stage are mainly characterized by high frequency, high performance, and high input power factor.

Get Started

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

Get Started

【Quality S2】DC 12V TO AC 220V 380V 500W

High energy efficiency,, low power consumption, convenient and safe to use, energy saving and, widely used in, night camps, night market vendors,

Get Started

Modular Solution Simplifies Design Of PFC Front End For

Jan 15, 2014 · PFC front-end and IGBT-based inverter stage features increased power density and increased ate-drive IC and PFC input stage, integrating more than 30 components into a

Get Started

Research on the Application of the High-Power SiC&Si

Dec 3, 2024 · This paper primarily discusses the hybrid application technology of high-voltage SiC MOSFETs and IGBTs in high-power three-level, three-phase inverters. It thoroughly utilizes

Get Started

A 5-kW unidirectional wireless power transfer EV charger

Jan 3, 2024 · A high-frequency (HF) inverter is connected to the DC link, and this HF inverter converts DC to AC and fed to transformer via LCC network. LCC network eliminates the ripple

Get Started

Infineon high voltage Inverter Application Presentation

May 25, 2025 · For EV traction inverter, more efficiency and right performance are key. While IGBT is ideal for cost-optimized drive-train, SiC demonstrates higher efficiency under WLTP

Get Started

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · pave way for isolated high-power and HFL inverters. They have attained significant attention with regard to wide applications encompassing high-power renewable- and

Get Started

Power Inverters Inverter Module, 500W Power Car Converter Board Front

Buy Power Inverters Inverter Module, 500W Power Car Converter Board Front Stage High: Power Inverters - Amazon FREE DELIVERY possible on eligible purchases

Get Started

High-frequency Inverter Design for a Wide Range of

Oct 29, 2023 · High-frequency Inverter Design for a Wide Range of Resistive and Reactive Load Variation Abstract: This paper proposes a design methodology for a high-frequency resonant

Get Started

6 FAQs about [High frequency inverter front stage module]

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

Which power supply topologies are suitable for a high frequency inverter?

The power supply topologies suitable for the High-Frequency Inverter includes push-pull, half-bridge and the full-bridge converter as the core operation occurs in both the quadrants, thereby, increasing the power handling capability to twice of that of the converters operating in single quadrant (forward and flyback converter).

What is a reference design for ANPC inverter power stage?

This reference design provides a design template for implementing a three-level, three-phase, gallium nitride (GaN) based ANPC inverter power stage. The use of fast switching power devices makes it possible to switch at a higher frequency of 100 kHz, reducing the size of magnetics for the filter and increasing the power density of the power stage.

Why do inverter power stages need bidirectional power transfer?

Another requirement that is becoming more prevalent for inverter power stages is the need for bidirectional power transfer. This is important in storage ready inverters where there can be a need for the power from the grid to be stored in local power storage like a battery.

What is a three-phase inverter reference design?

This reference design is built in a modular construction to allow easy replacement of power switching devices to allow easy comparison between them. The following boards combine to form this three-phase inverter reference design: A motherboard, comprising of the LCL filter, sensing electronics, bias power, switching relays and cooling fans.

What are the components of a 3 phase inverter?

The following boards combine to form this three-phase inverter reference design: A motherboard, comprising of the LCL filter, sensing electronics, bias power, switching relays and cooling fans. A TMDSCNCD280049C Control Card to support the DSP.

Related Articles

-

High frequency inverter front stage output

High frequency inverter front stage output

-

High frequency inverter produces 1200v

High frequency inverter produces 1200v

-

6000W high frequency inverter

6000W high frequency inverter

-

High frequency inverter for RV

High frequency inverter for RV

-

Low frequency inverter plus high voltage

Low frequency inverter plus high voltage

-

High frequency sine wave inverter

High frequency sine wave inverter

-

High frequency inverter rcd

High frequency inverter rcd

-

How many k is the best for high frequency inverter potentiometer

How many k is the best for high frequency inverter potentiometer

-

Stockholm High Frequency Inverter Installation

Stockholm High Frequency Inverter Installation

-

3600V high frequency inverter

3600V high frequency inverter

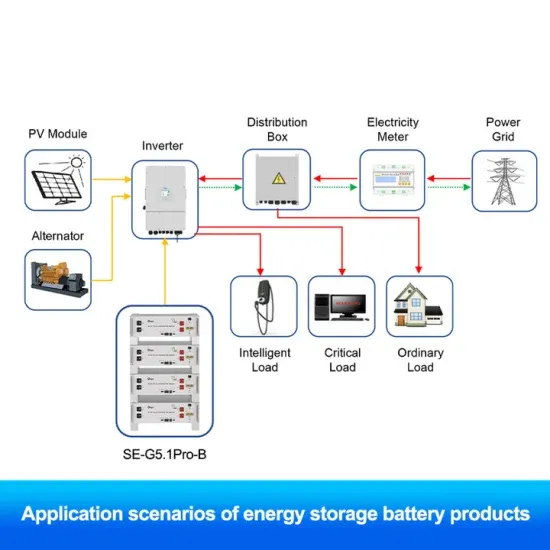

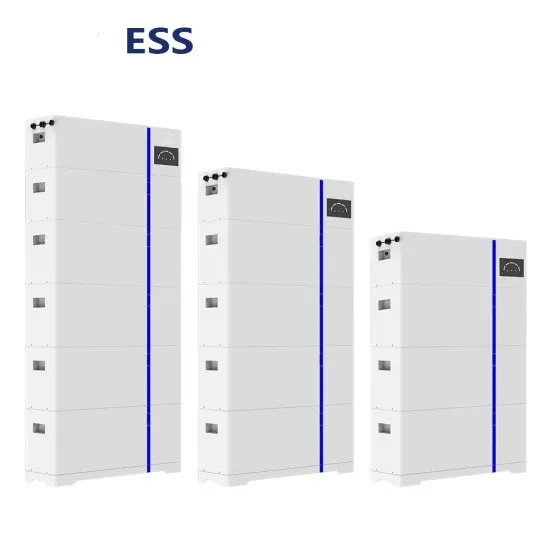

Commercial & Industrial Solar Storage Market Growth

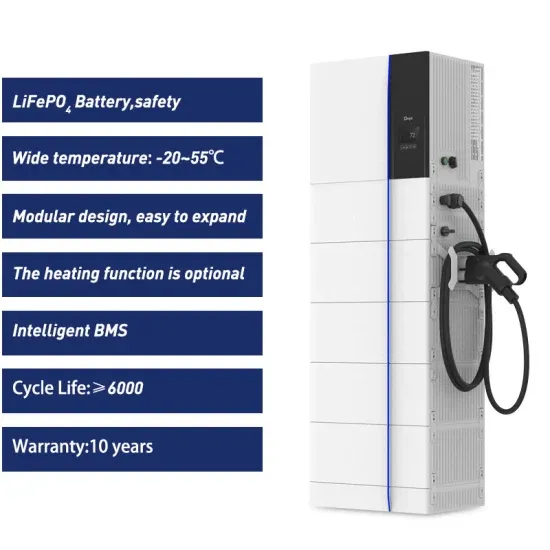

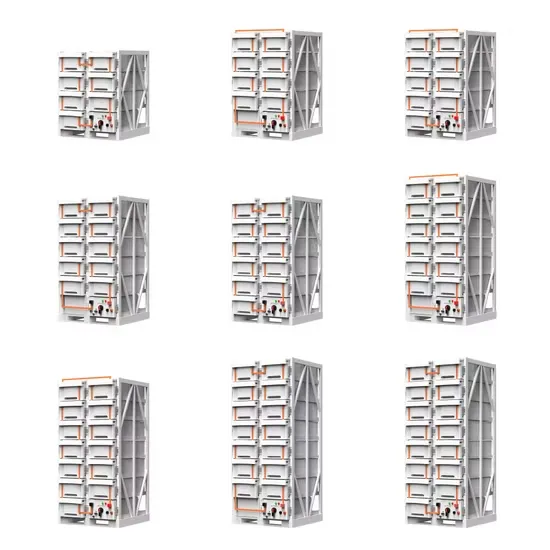

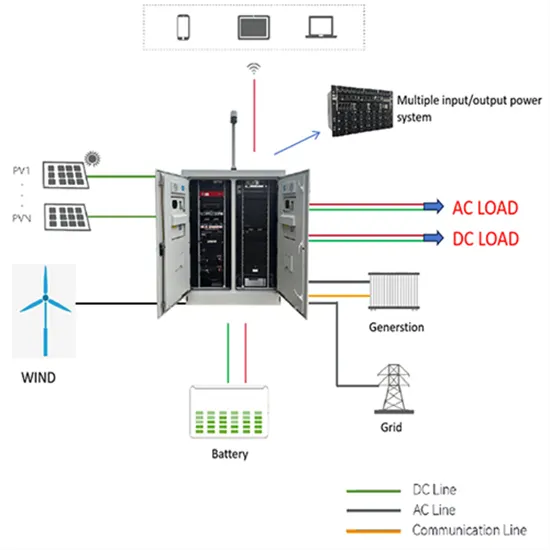

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.