Structural Steel in Renewable Energy

Structural steel is the sustainable choice for renewable energy systems and facilities. It''s strong, durable, and cost-effective for solar and more.

Get Started

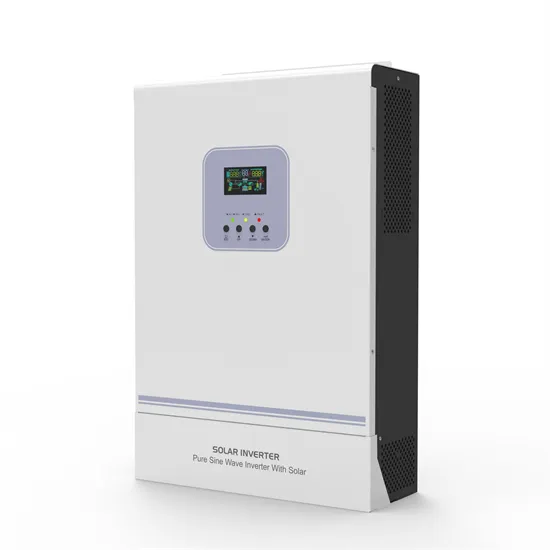

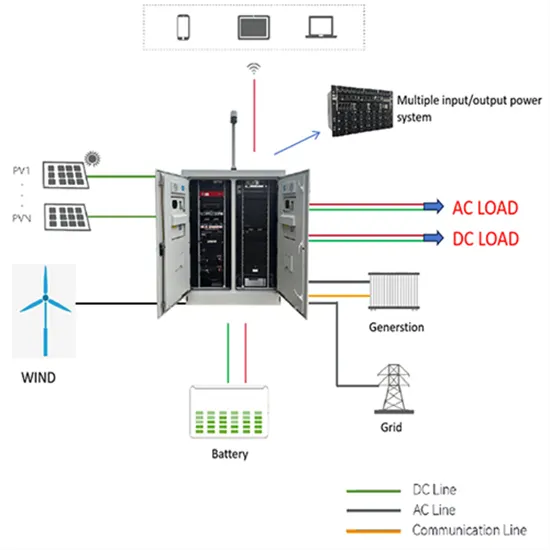

Efficient Energy Storage for Stable Steel

The steel industry''s high-power requirements make effective energy management essential. Our custom-designed energy storage solution not only addresses

Get Started

Move over, data centers. US steel mills need lots

Nov 18, 2024 · The United States is the world''s fourth-largest steel producer, and today, most of the country''s primary steel is made using coal in scorching-hot

Get Started

Energy Efficiency in Steel Mills | EOXS

May 3, 2025 · Smart Grids, with their ability to dynamically manage and optimize energy distribution, present an opportunity for steel mills to reduce costs, enhance sustainability, and

Get Started

Energy and Environment Management in Iron & Steel sector

ENERGY & ENVIRONMENT MANAGEMENT IN STEEL SECTOR Environment Management in Iron & Steel sector Iron & steel industry in India are covered under the Environment Protection

Get Started

Inherent potential of steelmaking to contribute to decarbonisation

Oct 24, 2018 · Accounting for ~8% of annual global CO 2 emissions, the iron and steel industry is expected to undertake the largest contribution to industrial decarbonisation. Despite the launch

Get Started

US pledges up to $1B for two pioneering ''green

Mar 26, 2024 · On Monday, the U.S. Department of Energy announced up to $ 6 billion for commercial-scale projects that aim to demonstrate technologies for

Get Started

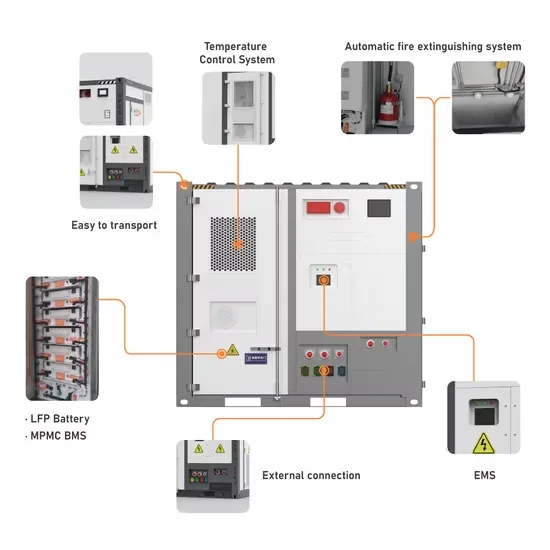

Steel Plant Energy Storage Power Stations: Solving Heavy

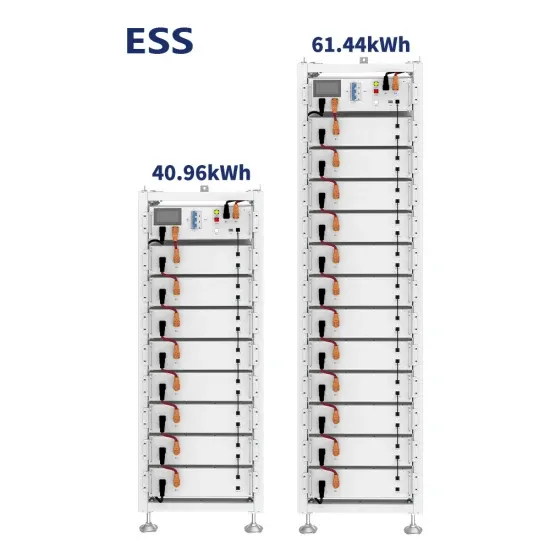

Three game-changing storage solutions are reshaping steel production: 1. Lithium-Iron Phosphate (LFP) Battery Arrays. With 15-minute response times and 95% round-trip efficiency, these

Get Started

Renewable Energy Integration in Steel Mills:

Oct 28, 2023 · Renewable energy in steel mills focuses on integrating wind, solar, and biomass energy sources to power production processes. Steel mills

Get Started

Hyundai Steel Expands into US With Electric Arc

Mar 25, 2025 · Hyundai Steel has unveiled plans for a US$5.8 billion electric arc furnace (EAF) -based integrated steel mill in Louisiana, US. The facility will

Get Started

Next-Generation Steel Mills | EOXS

6 days ago · The steel industry is at a transformative crossroads, with the push for sustainability and modernization reshaping the way mills operate. Next-generation steel mills are evolving to

Get Started

Competing for Green Steel: National advantages

Jan 11, 2024 · The variability of renewable energy sources, such as solar and wind, necessitates oversizing of capacity and the implementation of energy

Get Started

Old West Virginia Steel Mill Becomes a Green-Energy

Sep 17, 2023 · Form Energy''s rust-powered batteries are critical piece of clean-energy puzzle WEIRTON, W.Va.—For decades, iron ore was shipped into a sprawling steel mill on the banks

Get Started

Assisting the green transformation of steel plants, the

Nov 1, 2024 · This 30MW/60MWh energy storage power station project was born in response to the green transformation needs of the steel industry. The project adopts a string energy

Get Started

Green Steel: pathways for the new hydrogen

Apr 4, 2024 · Green hydrogen is set to transform the steel industry. Hydrogen-based direct reduction (DR) technology is already leaving behind other

Get Started

How Electrification of Steel Mills Cuts Carbon

Mar 20, 2024 · Regional collaborations, such as energy partnerships or government incentives, can further ease the transition and enhance

Get Started

Green and circular: the future of stainless steel

Aug 26, 2024 · Stainless steel plays a crucial role in the green transition, as it finds multiple applications in low- and zero-carbon energy (wind, wave, solar,

Get Started

Low carbon optimal planning of the steel mill gas utilization

Aug 1, 2023 · About 34% of the energy stored in coal is converted into the steel mill gases during the production process, including blast furnace gas (BFG), coke oven gas (COG) and Linz

Get Started

U.S. Energy Storage Industry Commits $100

WASHINGTON, D.C., April 29, 2025 – Today the American Clean Power Association (ACP), on behalf of the U.S. energy storage industry, announced

Get Started

Steel: an enabler and a threat to the energy

Jun 19, 2025 · Steel is a critical component of the energy transition. We need it to build renewable energy infrastructure; wind turbines, solar panels and dam

Get Started

China''s Metallurgical Energy Storage: Powering the Future of Steel

a steel mill that cuts energy costs by 30% while reducing carbon emissions. That''s not sci-fi—it''s happening right now in China''s metallurgical sector. As the world''s largest steel producer

Get Started

Steel Production in America: A New Era of

Apr 11, 2025 · As the world races toward a more sustainable future, the steel industry in the United States stands at a pivotal crossroads. Steel, a backbone

Get Started

Eos DOE loan, UBS AI platform, Solar and steel

Dec 5, 2024 · Green & Clean Power has begun construction on the renewables-plus-storage plant at sister company Hybar''s recycled steel mill in Osceola, Arkansas. Image:

Get Started

Fact sheet Energy use in the steel industry

May 27, 2022 · Energy use in the steel industry ndustry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry

Get Started

Powering tomorrow''s steel mills with nuclear energy

Mar 23, 2023 · The iron and steel industry accounts for more than 7% of direct anthropogenic GHG emissions globally, close to 10% when including indirect emissions. This presents an

Get Started

Green steel: The two-track transformation of modern

Jun 12, 2025 · For steel producers beginning their decarbonization journey, the path forward typically follows these steps: Establish your energy strategy. Determine how you will source

Get Started

Powering cleaner steelmaking in India: Electricity from

May 8, 2025 · ArcelorMittal''s largest renewable energy venture, a 1GW solar and wind project located in Andhra Pradesh, southern India, has recently started providing clean electricity to

Get Started

What are the energy storage power stations in

May 8, 2024 · The integration of energy storage solutions allows steel plants to harness surplus energy during peak production, store it, and deploy it when

Get Started

The economic case for green steel production at a | Canary

Nov 19, 2024 · Now clean energy and environmental justice advocates are proposing that the city play a lead role in greening the auto industry, through a transformation of the Dearborn Works

Get Started

Exploring Trends in Energy Storage Solutions for Steel

Aug 10, 2025 · The integration of advanced energy storage solutions is crucial for the future of steel manufacturing. By adopting technologies such as battery storage, thermal energy

Get Started

Carbon capture in the steel industry: ArcelorMittal,

Oct 27, 2022 · The agreement, which involves a trial at ArcelorMittal''s steel plant in Gent, Belgium and another site in North America, brings together the expertise of the various partners in

Get Started

Powering tomorrow''s steel mills with nuclear energy

Mar 23, 2023 · The iron and steel industry accounts for more than 7% of direct anthropogenic GHG emissions globally, close to 10% when including indirect emissions. This presents an

Get Started

6 FAQs about [Does the steel mill undertake energy storage projects ]

How does steel save energy?

Fact sheetEnergy use in the steel industryThe steel ndustry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to minimise environmenta impacts, such as greenhouse gas emissions. Steel saves energy over its many life cycles through its 100% recyclab

Why is energy conservation important in steelmaking?

ndustry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to minimise environmenta impacts, such as greenhouse gas emissions. Steel saves energy over its many life cycles through its 100% recyclab lity, durability and lightweight potential.World crude steel prod

How does energy eficiency affect steel production?

air, water and land for 17 steel products. The LCI data is av eel.org.Energy inputs and associated costsEnergy constitutes a significant portion of the cost of steel production, from 20% to 40%.2, 3 Thus, improvements in energy eficiency result in reduced production

What is a gas used for in a steel plant?

dditional fossil fuel and energy resources. They typically contribute to more than 60% of a steel plant’s energy requirements and are used either as a direct fuel substitute or for the generation of electricity.7Alternatively, gases can be us d for power generation or exported of-site. They are flar

How is steel produced?

readiness levels.Steel production basicsSteel is produced via two main routes: the blast furnace-basic oxygen furnace (BF-BOF) route and electric arc furnace (EAF) route. Variations and c mbinations of production routes also exist.The BF-BOF route produces steel using raw materials such a iron ore, coal, limestone and steel scrap. About 75%

What percentage of steel is produced via the EAF route?

25% of steel is produced via the EAF route.Most steel products remain in use for decades or even centuries before their function is no longer needed and they can then be reused, remanufactured or recycled. Therefore, there is not e

Related Articles

-

Which steel materials are more commonly used in energy storage projects

Which steel materials are more commonly used in energy storage projects

-

Suggestions for promoting energy storage projects

Suggestions for promoting energy storage projects

-

Four major energy storage projects

Four major energy storage projects

-

Are there any energy storage projects in Penang Malaysia

Are there any energy storage projects in Penang Malaysia

-

Safety construction plan for energy storage projects

Safety construction plan for energy storage projects

-

New investment projects in Taipei energy storage

New investment projects in Taipei energy storage

-

How much is the subsidy for energy storage projects in New York USA

How much is the subsidy for energy storage projects in New York USA

-

Large-scale energy storage projects and lithium batteries

Large-scale energy storage projects and lithium batteries

-

Latest electricity prices for South Asia energy storage projects

Latest electricity prices for South Asia energy storage projects

-

Multiple energy storage power generation projects

Multiple energy storage power generation projects

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.