Channel structure design and optimization for immersion cooling

Jan 30, 2024 · In this study, four cooling channel design schemes (CC-1, CC-2, CC-3, and CC-4) for the BICS were developed. The effect of various cooling channel structures on the cooling

Get Started

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Get Started

Understanding battery liquid cooling system

6 days ago · The battery liquid cooling system has high heat dissipation efficiency and small temperature difference between battery clusters, which can improve

Get Started

High-uniformity liquid-cooling network designing approach for energy

Nov 1, 2024 · This investigation presents an efficient liquid-cooling network design approach (LNDA) for thermal management in battery energy storage stations (BESSs). LNDA can output

Get Started

Multi-objective topology optimization design of liquid-based cooling

Feb 1, 2025 · Multi-objective topology optimization design of liquid-based cooling plate for 280 Ah prismatic energy storage battery thermal management

Get Started

CATL EnerC 0.5P Energy Storage Container

Jul 3, 2025 · Description EnerC liquid-cooled energy storage battery containerized energy storage system is an integrated high energy density

Get Started

CATL 0.5P EnerOne+ Outdoor Liquid Cooling Rack

Aug 1, 2025 · Controlbox Control box mainly includes detection device, protection device andAC/DC power supply. The structure is shown as follows. EnerOne+

Get Started

WHAT IS A SIMPLE LIQUID COOLING LC STRUCTURE

The liquid-cooled energy storage system integrates the energy storage converter, high-voltage control box, water cooling system, fire safety system, and 8 liquid-cooled battery packs into

Get Started

Battery Energy Storage

Active water cooling is the best thermal management method to improve battery pack performance. It is because liquid cooling enables cells to have a more uniform temperature

Get Started

Two-phase immersion liquid cooling system for 4680 Li-ion

Sep 10, 2024 · Introduction Lithium-ion batteries are widely adopted as an energy storage solution for both pure electric vehicles and hybrid electric vehicles due to their exceptional energy and

Get Started

Design and optimization of air-cooled heat dissipation structure

Jul 15, 2024 · Generally, heat dissipation solutions for supercapacitor box could be divided into three kinds of strategies: air cooling, liquid cooling and PCM cooling [26]. Because of its low

Get Started

Liquid-Cooled Battery Energy Storage System

High-power battery energy storage systems (BESS) are often equipped with liquid-cooling systems to remove the heat generated by the batteries during

Get Started

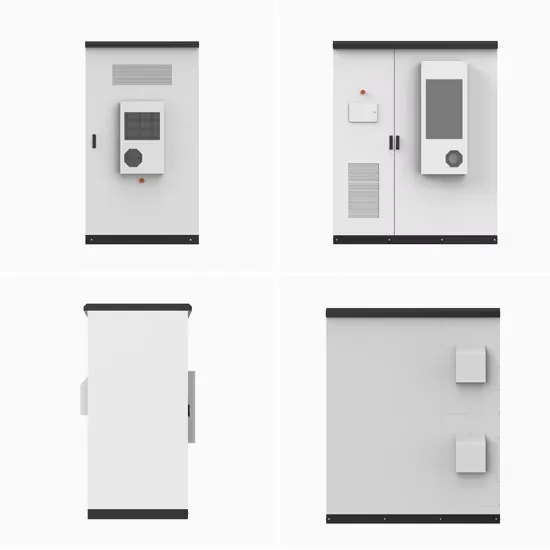

0.5P EnerOne+ Outdoor Liquid Cooling Energy

Aug 12, 2025 · Application The EnerOne+ Rack is a modular fully integrated product, consisting of rechargeable lithium-ion batteries, with the

Get Started

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

Jul 7, 2025 · Against the backdrop of accelerating energy structure transformation, battery energy storage systems (ESS) are widely used in commercial and industrial applications, data

Get Started

Research and design for a storage liquid refrigerator

Aug 9, 2024 · At present, energy storage in industrial and commercial scenarios has problems such as poor protection levels, flexible deployment, and poor battery performance. Aiming at

Get Started

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · Discover how liquid cooling enhances energy storage systems. Learn about its benefits, applications, and role in sustainable power solutions.

Get Started

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integra

Get Started

考虑到储能电池特性的储液冰箱研究与设计

Aug 9, 2024 · At present, energy storage in industrial and commercial scenarios has problems such as poor protection levels, flexible deployment, and poor battery performance. Aiming at

Get Started

Energy Storage Liquid Cooling Container Design: The Future

Dec 8, 2023 · Energy storage liquid cooling container design is the unsung hero behind reliable renewable energy systems, electric vehicles, and even your neighborhood data center. Let''s

Get Started

Middle article: Liquid-tight design of energy storage liquid cooling

Dec 20, 2024 · Liquid-tight design refers to the design method of achieving liquid tightness in a product or system to prevent liquid leakage or penetration. The factors that affect the sealing

Get Started

Liquid Cooling in Energy Storage | EB BLOG

Oct 22, 2024 · Explore the evolution from air to liquid cooling in industrial and commercial energy storage. Discover the efficiency, safety, and performance

Get Started

Fin structure and liquid cooling to enhance heat

Feb 3, 2023 · The new BTMS has significantly improved the secondary heat storage problem of PCMs and the temperature uniformity of LIBs. The fin

Get Started

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

Get Started

Frontiers | Research and design for a storage liquid

Aug 9, 2024 · The key system structure of energy storage technology comprises an energy storage converter (PCS), a battery pack, a battery management system (BMS), an energy

Get Started

373kWh Liquid Cooled Energy Storage System

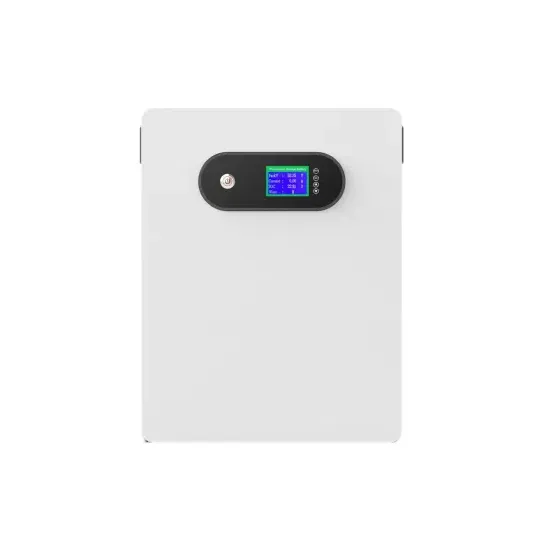

5 days ago · 1500V Liquid Cooled Battery Energy Storage System (Outdoor Cabinet). Easily expandable cabinet blocks can combine for multi MW BESS projects.

Get Started

Optimized design of liquid-cooled plate structure for flying

Sep 1, 2024 · Under the same conditions, a comparative simulation analysis of the performance of four different BTMS structures was conducted in terms of cooling efficiency, energy

Get Started

Design and testing of a high performance liquid phase cold storage

Dec 15, 2020 · The cold storage efficiency experimental result of the liquid phase cold storage system for liquid air energy storage was firstly obtained, and two-stage cold storage

Get Started

Battery energy storage system (BESS) container,

5 days ago · BESS (Battery Energy Storage System) is an advanced energy storage solution that utilizes rechargeable batteries to store and release

Get Started

CATL 0.5P EnerOne+ Outdoor Liquid Cooling Rack

Dec 6, 2023 · Controlbox Control box mainly includes detection device, protection device andAC/DC power supply. The structure is shown as follows. EnerOne+

Get Started

6 FAQs about [Energy storage liquid cooling box structure]

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a liquid-cooling high voltage box?

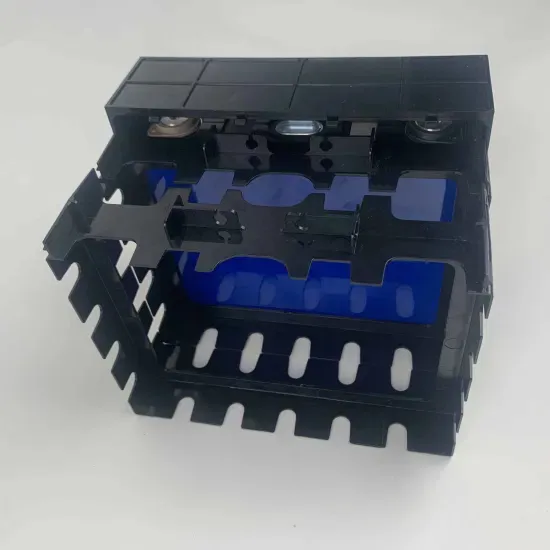

The liquid-cooling high voltage box is chiefly installed in the energy storage liquid-cooling battery cluster and manages the power on/off for the battery cluster system. It also connects to battery cluster high voltage and signal output interfaces. The liquid-cooling high voltage box must meet the following requirements:

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

Related Articles

-

Liquid cooling energy storage cabinet structure

Liquid cooling energy storage cabinet structure

-

Luxembourg 210 degree liquid cooling energy storage cabinet foreign trade

Luxembourg 210 degree liquid cooling energy storage cabinet foreign trade

-

Energy storage battery air cooling and liquid cooling

Energy storage battery air cooling and liquid cooling

-

Liquid Cooling Energy Storage Cabinet Configuration

Liquid Cooling Energy Storage Cabinet Configuration

-

Rabat liquid cooling energy storage container selling price

Rabat liquid cooling energy storage container selling price

-

Liquid filling machine for energy storage cabinet liquid cooling unit

Liquid filling machine for energy storage cabinet liquid cooling unit

-

Bogota Liquid Cooling Energy Storage Solution

Bogota Liquid Cooling Energy Storage Solution

-

Energy Storage Liquid Cooling Solution

Energy Storage Liquid Cooling Solution

-

Electryl glycol for energy storage cabinet liquid cooling system

Electryl glycol for energy storage cabinet liquid cooling system

-

Huawei Liquid Cooling Energy Storage in Dubai UAE

Huawei Liquid Cooling Energy Storage in Dubai UAE

Commercial & Industrial Solar Storage Market Growth

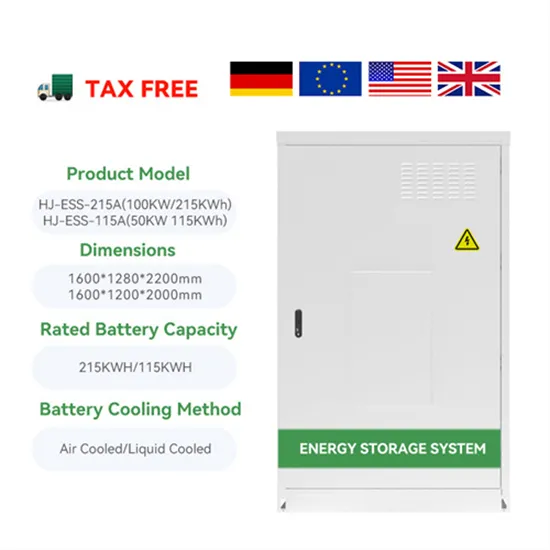

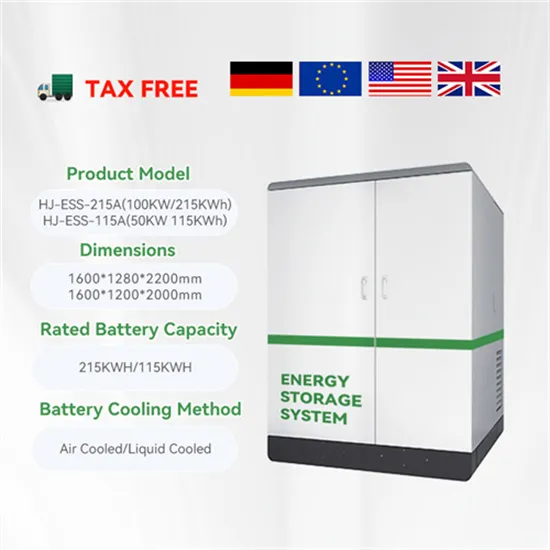

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.