IS 1652 (1991): Stationary cells and batteries,lead-acid

Nov 15, 2018 · dimensions, capacities andperformance requirements of stationary cells and batteries of lead-acid type with plante positive plates. Forpreparation of this standard,

Get Started

Industry standard sealed lead acid battery size and VRLA charts

Feb 7, 2023 · Standardized SLA Battery size information for design engineers including 12V, 6V, 4V battery voltages

Get Started

Car Battery Types and Their Weight. (For

The separator needs to be a bit larger than plates to prevent a short circuit. The fourth component is the electrolyte. The lead plates are submerged in an

Get Started

How Much Does a Car Battery Weigh?

Mar 2, 2025 · Discover why battery weight matters for gas, hybrid, and EV performance. Technical breakdown of Li-ion (150-250 Wh/kg), LiFePO4

Get Started

Choosing the Right Battery for Base Stations: LiFePO4 vs. Lead-Acid

Explore the critical considerations in selecting batteries for base stations. This comparison between LiFePO4 and lead-acid batteries delves into power consumption, backup time, and

Get Started

SECTION 6: BATTERY BANK SIZING PROCEDURES

Jun 14, 2022 · System Voltage Batteries are comprised of multiple series-connected cells For lead-acid batteries at 100% SoC, nominal voltage is 2.1 V/cell Common battery configurations:

Get Started

Battery Sizing Considerations IEEE 2020

Mar 11, 2020 · NiCad batteries typically operate between 1.00vpc and up to 1.65vpc depending on load voltage tolerance. 125Vdc: 105Vdct to 140Vdc *Should be based on equipment

Get Started

Car Battery Weight Guide (2025):

Apr 1, 2025 · Car battery weight varies significantly—from 10 pounds for lightweight lithium options to over 70 pounds for heavy-duty lead-acid

Get Started

Weight of lead-acid battery for communication base station

Energy storage lead-acid batteries for power supply and communication base stations meet the technical needs of modern telecom operators who tend to integrate, miniaturize, and lighten

Get Started

TECHNICAL MANUAL SEALED LEAD-ACID BATTERIES

Oct 24, 2019 · Sealed/Maintenance–Free The valve regulated spill proof construction allows trouble-free safe operation in any position. There is no need to add electrolyte, as gases

Get Started

Battery testing guide

Apr 25, 2022 · Planté invented the lead-acid battery in 1859 and in 1881 Faure first pasted lead-acid plates. With refinements over the decades, it has become a critically important back-up

Get Started

Battery Sizing Explained

Oct 11, 2022 · Our calculations are based on the IEEE-provided standards for the sizing of both nickel -cadmium and lead-acid station application batteries. This

Get Started

Lead Acid Battery Weight: How Much Does a Lead Acid Battery

Mar 16, 2025 · What Is the Average Weight of a Lead Acid Battery? The average weight of a lead acid battery varies based on its size and capacity, typically ranging from 30 to 50 pounds (13.6

Get Started

Lead-acid Battery for Telecom Base Station Market

The telecom base station sector relies on lead-acid batteries due to their cost-effectiveness, reliability, and adaptability to harsh environments. Expanding 4G and 5G infrastructure in

Get Started

Comparison of LiFePO4 battery and lead-acid battery in base station

Explore the critical considerations in selecting batteries for base stations. This comparison between LiFePO4 and lead-acid batteries delves into power consumption, backup time, and

Get Started

BU-214: Summary Table of Lead-based Batteries

Jan 15, 2024 · The lead acid battery maintains a strong foothold as being rugged and reliable at a cost that is lower than most other chemistries. The global

Get Started

How Much Does a Car Battery Weigh? A

Sep 2, 2024 · The average weight of a standard 12-volt lead-acid car battery ranges from 30 to 50 pounds (13.6 to 22.7 kg). This weight is largely due to

Get Started

S-740v2020-12

Jan 18, 2021 · The batteries shall be supplied with insulated inter-cell connectors made of tin or lead-plated copper bus bars or cables using stainless steel 316 hardware for fixing.

Get Started

Weight standard of lead-acid batteries in computer rooms

tages of sealed lead acid batteries: 1. Weight and Size. Sealed lead acid batteries are generally heavier and larger co pared to other types of batteries with similar capacity. This can limit their

Get Started

OPzS-2V Cell Datasheet

Jul 26, 2019 · The BAE OPzS Series flooded tubular plate cells are one of the most enduring lead acid batteries on the market today. They are ideally suited for stand-by operations as well as

Get Started

Edition 8.0 2018-11 INTERNATIONAL STANDARD

Jan 26, 2021 · LEAD-ACID STARTER BATTERIES – Part 1: General requirements and methods of test FOREWORD ical committees (IEC National Committees). The object of IEC is to

Get Started

National standard for lead-acid battery weight

The weight of a lead-acid battery can vary depending on the size and type of the battery. On average, a standard lead-acid battery for a truck weighs between 40 to 60 pounds (18 to 27

Get Started

Long‐Life Lead‐Carbon Batteries for Stationary

Dec 20, 2023 · Abstract Owing to the mature technology, natural abundance of raw materials, high recycling efficiency, cost-effectiveness, and high safety of

Get Started

LEAD ACID BATTERIES

Aug 2, 2021 · 1. Introduction Lead acid batteries are the most common large-capacity rechargeable batteries. They are very popular because they are dependable and inexpensive

Get Started

Battery Types in Portable Power Stations: Lithium-ion vs. Lead-Acid

Aug 11, 2025 · Get the Most Out of Your Portable Power Station with Pisen While lead-acid batteries have their benefits, there''s no denying that lithium-ion batteries are the best batteries

Get Started

1 Battery Storage Systems

Feb 2, 2018 · 41 VRLA types present distinct advantages and disadvantages. While the technology is well-known and can offer a lower-cost advantage, lead-acid batteries have

Get Started

BS 6290

This is a multi-part document divided into the following parts: Part 1 Lead-acid stationary cells and batteries. Specification for general requirements Part 2 Lead-acid stationary cells and

Get Started

BS 6290

Part 1 Lead-acid stationary cells and batteries. Specification for general requirements. Part 2 Lead-acid stationary cells and batteries. Specification for lead-acid high performance Planté

Get Started

IS 14257 (1995): Lead-acid storage batteries for motor

Nov 15, 2018 · This standard covers characteristics, dimensions and tests for light weight lead acid storage batteries with a rated voltage of 12 volts to be used as power for starting and

Get Started

Lead-Acid vs. Lithium-Ion Batteries for Telecom

Mar 7, 2025 · While lead-acid batteries remain a cost-effective option, lithium-ion batteries are gaining popularity due to their longer lifespan, reduced

Get Started

Base station lead-acid energy storage

Telecom Base Station Lithium Battery Electric Energy Storage Communication Transportation Power Data Security Lithium Battery Built for extreme temperature operation up to 50% in

Get Started

Lithium battery is the magic weapon for

Jan 13, 2021 · China''s communication energy storage market has begun to widely used lithium batteries as energy storage base station batteries, new

Get Started

IEEE Stationary Battery Standards Collection: VuSpecTM

Oct 21, 2022 · Battery types include rechargeable lead-acid, nickel-cadmium, and other types used or proposed for use in stationary applications. Table of Contents Includes 36 active IEEE

Get Started

6 FAQs about [Base station lead-acid battery weight standard]

How much does a lead acid battery weigh?

Lead acid batteries typically weigh more than many other common battery types. A standard car lead acid battery weighs between 30 to 50 pounds (14 to 23 kilograms). In contrast, lithium-ion batteries, often used in smartphones and electric vehicles, weigh significantly less.

Are lead acid batteries portable?

Portability challenges arise from the substantial weight of lead acid batteries. Lead acid batteries generally weigh between 30 to 70 pounds (13.6 to 31.8 kg). This weight makes them less convenient for applications requiring frequent transport, like portable devices.

Why are lead acid batteries important in energy storage technology?

This information underlines their significance in energy storage technology. The heavy nature of lead acid batteries can affect transportation costs and energy efficiency in vehicles, potentially increasing environmental impact. Health risks exist due to the lead and sulfuric acid content in these batteries.

What are the different parts of the lead-acid cell specification?

Part 1 Lead-acid stationary cells and batteries. Specification for general requirements Part 2 Lead-acid stationary cells and batteries. Specification for lead-acid high performance Planté positive type Part 3 Lead-acid stationary cells and batteries. Specification for lead-acid pasted positive plate type

How much does a lithium ion battery weigh?

On average, lithium-ion batteries weigh about 30-50% less than their lead-acid counterparts for the same energy capacity. For example, a 12-volt, 100 amp-hour lead-acid battery generally weighs around 60-70 pounds (27-32 kilograms), whereas a comparable lithium-ion battery of the same capacity weighs approximately 30-40 pounds (14-18 kilograms).

How much do AGM batteries weigh?

AGM (Absorbent Glass Mat) batteries weigh differently compared to traditional lead-acid batteries. AGM batteries typically weigh less due to their design and materials. For example, a standard 12V AGM battery can weigh around 30-50 pounds, while a comparable lead-acid battery may weigh 40-60 pounds.

Related Articles

-

Naypyidaw Telecommunication Base Station Lead-acid Battery Maintenance Company

Naypyidaw Telecommunication Base Station Lead-acid Battery Maintenance Company

-

Bhutan communication base station lead-acid battery lightning protection

Bhutan communication base station lead-acid battery lightning protection

-

East Africa Communication Base Station Lead-acid Battery Maintenance Project

East Africa Communication Base Station Lead-acid Battery Maintenance Project

-

Sarajevo communication base station lead-acid battery installation plan

Sarajevo communication base station lead-acid battery installation plan

-

Solar base station lead-acid battery residents

Solar base station lead-acid battery residents

-

Vientiane Communication Base Station Lead-acid Battery Photovoltaic Power Generation External Machine Cooling

Vientiane Communication Base Station Lead-acid Battery Photovoltaic Power Generation External Machine Cooling

-

Base station lead-acid battery heating up when charging

Base station lead-acid battery heating up when charging

-

Standard storage location base station for lithium battery station cabinet

Standard storage location base station for lithium battery station cabinet

-

How to build a lead-acid battery for a wireless communication base station

How to build a lead-acid battery for a wireless communication base station

-

Ljubljana communication base station lead-acid battery cabinet in stock

Ljubljana communication base station lead-acid battery cabinet in stock

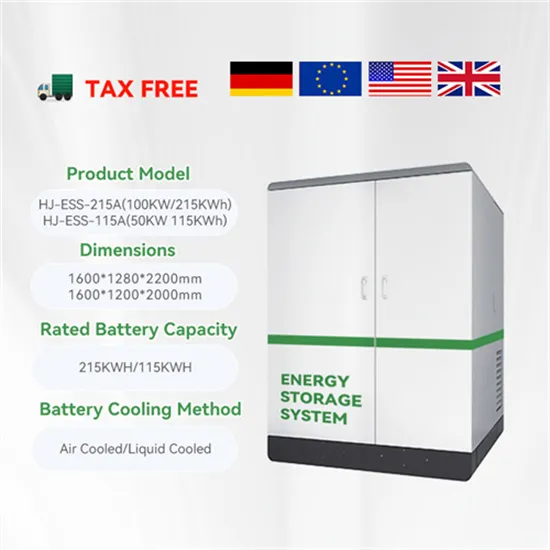

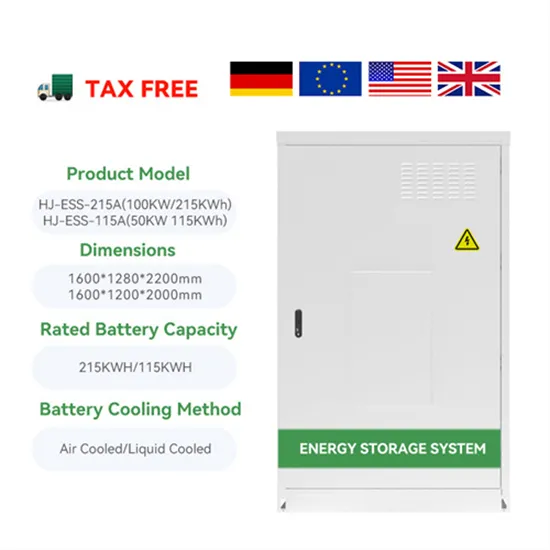

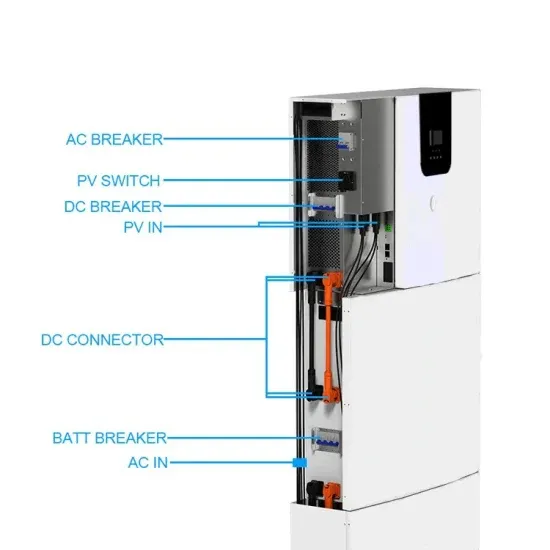

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.