What Materials Form Lithium Batteries? A

Apr 9, 2024 · What are lithium batteries made of? Explore the fundamental components and inner workings of these indispensable power sources.

Get Started

What Materials Are Needed for Lithium Battery

Mar 28, 2025 · Discover the essential materials used in lithium battery production. Learn about cathodes, anodes, plus how manufacturers ensure quality and

Get Started

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

Get Started

What Are the Raw Materials Used in Lithium-Ion Batteries?

Apr 23, 2025 · Lithium-ion batteries are composed of several key raw materials that significantly influence their performance and efficiency. The primary materials include lithium, cobalt,

Get Started

Battery Enclosures Tech Sheets

Dec 4, 2023 · These complex assemblies are available in steel, aluminum, and multi-material configurations including lightweight composites. With Magna''s engineering and manufacturing

Get Started

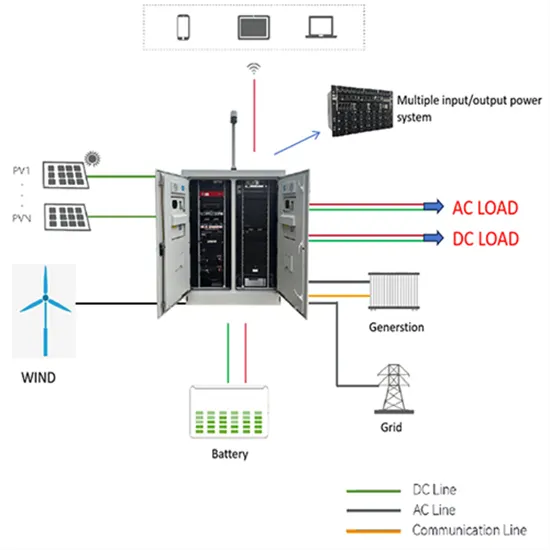

Battery cabinets are process materials

A battery cabinet system is an integrated assembly of batteries enclosed in a protective cabinet, designed for various applications, including peak shaving, backup power,

Get Started

What are the companies that produce battery cabinets

4 Companies Leading The Rise Of Lithium And Battery Technology Batteries with NMC 811 cathodes and other nickel-rich batteries, require lithium hydroxide. 5 By 2021, the company

Get Started

What Materials Are Used in Lithium-ion Batteries?

May 30, 2025 · Lithium-ion batteries are composed of specialized materials that work together to store and deliver energy efficiently. To understand what a lithium-ion battery is made of, it''s

Get Started

What battery material enclosure is recommended? Steel or

Aug 16, 2025 · Aluminum is the most common material used. Aluminum is more corrosion-resistant, has superior thermal conductivity, but most off all it is chosen because it provides

Get Started

What Are Batteries Made Of? The Surprising

Jan 28, 2025 · Batteries are made of an intriguing blend of metals and natural materials. Common components include aluminum, sulfur, and even plant

Get Started

Choosing the right material for battery containers

Apr 4, 2025 · Choosing the Ideal Material for Battery Containers: Striking the Right Balance. Battery containers are essential for ensuring the safety,

Get Started

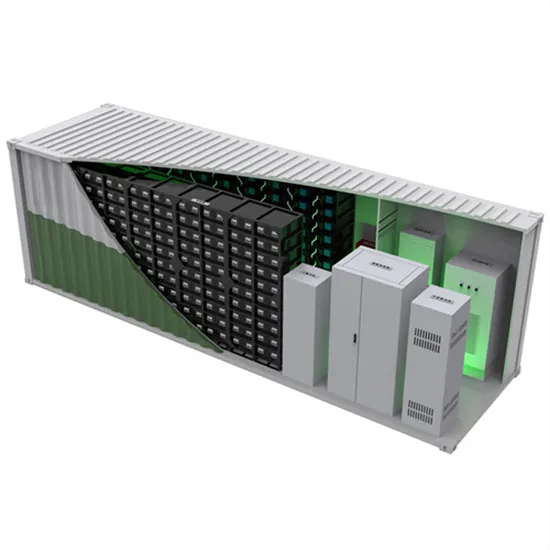

What is an energy storage battery cabinet?

May 22, 2024 · A comprehensive examination of an energy storage battery cabinet reveals that it serves as a vital component in modern energy

Get Started

The 7 Most Common Plastics in Automotive

Apr 30, 2023 · Discover the 7 Most Common Plastics in Automotive Batteries, crucial for safety, performance, and reliability. Learn how each polymer

Get Started

What Are Batteries Made Of?

May 1, 2023 · What are batteries made of? Check out this article and find out what exactly batteries are made of and how the materials work together to

Get Started

How to Build a Battery: An In-Depth

Dec 17, 2024 · Curious how batteries are made? This guide covers the materials, tools, and steps for producing different types, with a focus on lithium-ion

Get Started

Complete Guide for Battery Enclosure

Oct 7, 2024 · Energy storage cabinets primarily utilize 1. advanced composite materials, 2. metals, and 3. insulation technology. Advanced composite

Get Started

What materials are used in the battery cabinet

y Cabinets. Why use a battery storage cabinet? Axil steel cabinets and boxes provide a dedicated and controlled environment for the housi g and charging of batteries and other devices. A cool,

Get Started

What are the materials for photovoltaic battery cabinets

Bespoke Battery Cabinets M+H Power Battery Cabinets are offered with our range of GenZ batteries or are ideally suited to the Selectronic range of SP PRO off-grid inverters. Save Time

Get Started

What materials are the battery cabinets made of

What material should a battery box be made of? In most cases, you will find aluminum and stainless steel battery cabinets. Of course, we have galvanized steel, plastic, and composite

Get Started

Battery cabinets prevent and reduce the risk of lithium batteries

To address this issue, manufacturers have developed a new type of safety equipment: battery storage cabinets, also known as lithium-ion battery charging and storage cabinets, designed to

Get Started

What Are The Raw Materials For Making Battery

Dec 14, 2022 · Raw Materials Use in Lithium Ion Battery Manufacturing The lithium, graphite, cobalt and manganese used to manufacture lithium ion

Get Started

Battery Enclosure

Battery enclosure is defined as a container designed for batteries that addresses material selection and heat transfer to ensure safety and longevity, typically utilizing plastic for its

Get Started

From Raw Materials to Finished Product: The

Nov 10, 2024 · Introduction Lithium-ion batteries are the most used batteries worldwide. This is because they are known as an important technology for

Get Started

The Ultimate Guide to Lithium-Ion Battery

Mar 21, 2025 · Discover the importance of lithium-ion battery storage cabinets for safe battery storage and charging. Learn best practices, key features, and

Get Started

11 Types of Cabinet Materials: From MDF to

May 1, 2023 · Planning a remodel? Discover the pros and cons of the most popular types of cabinet materials, such as solid wood, plywood, and MDF.

Get Started

What Is a Battery Rack Cabinet and Why Is It Essential?

Jun 14, 2025 · A battery rack cabinet is a specialized enclosure designed to securely house multiple batteries in energy storage systems. It ensures thermal management, safety, and

Get Started

Battery materials for electric vehicle – A comprehensive review

Jan 1, 2023 · To achieve sustainability, batteries must operate beyond their current capabilities in terms of longevity, reliability, and safety. In addition, the chemicals and materials used in the

Get Started

Why Are Lithium Battery Casings Made of Aluminum?

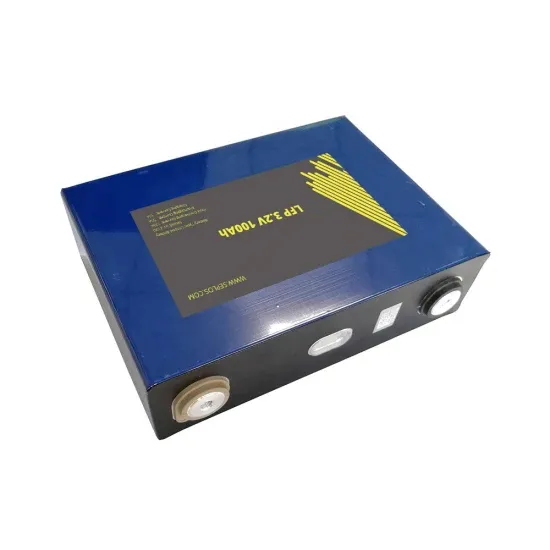

Lithium batteries are one of the most commonly used battery types in daily life. Whether it''s cylindrical IMR 18650 batteries or prismatic lithium iron phosphate batteries, aluminum casings

Get Started

What Are the Essential Raw Materials for Lithium

May 3, 2025 · Lithium-ion batteries rely on materials like lithium, cobalt, nickel, graphite, and manganese for energy storage, stability, and performance in

Get Started

4 Casing Types for Lithium Batteries: Complete

Delve into the characteristics of four common casing materials for lithium batteries: PVC, plastic, metal, and aluminum. Help you to choose

Get Started

What Materials Are Used In The Production Of

Feb 23, 2024 · Lithium-Ion Batteries Lithium-ion batteries are the powerhouse behind electric vehicles, providing the energy needed for them to run

Get Started

6 FAQs about [What are the materials used to produce battery cabinets ]

What material should a battery box be made of?

In most cases, you will find aluminum and stainless steel battery cabinets. Of course, we have galvanized steel, plastic, and composite materials. A good material for the battery box should be: So far, aluminum and stainless steel guarantee better performance. Apart from these 4, you may classify battery box enclosures depending on:

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

What is a battery case made of?

The battery housing is made of a specific plastic material, which has to be chemically compatible with the acid electrolyte. By the use of plastic materials (mostly polypropylene) the battery case is electrically insulated from the electrode system.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

What should a battery cabinet have?

Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no movement). Cooling plates – some have cooling plates that help to control the enclosure temperature. Insulation system – insulation is also a safety measure a battery cabinet should have.

What are structure-battery materials?

A term “structure-battery” materials has been applied to such designs [90,96]. This approach targets elimination of inert mass of the battery enclosure by placing the battery cells within the structural components with no, or minimal, modification done to the cells.

Related Articles

-

What are the manufacturers of rechargeable battery cabinets in Sri Lanka

What are the manufacturers of rechargeable battery cabinets in Sri Lanka

-

What kind of battery is used for amorphous inverter

What kind of battery is used for amorphous inverter

-

What kind of battery is used in large energy storage power stations

What kind of battery is used in large energy storage power stations

-

What is the price of 8 battery cabinets

What is the price of 8 battery cabinets

-

What are the battery cabinets for new energy electric boats

What are the battery cabinets for new energy electric boats

-

What is the appropriate safety distance between battery cabinets

What is the appropriate safety distance between battery cabinets

-

What kind of battery should be used for outdoor power supply

What kind of battery should be used for outdoor power supply

-

What are the accessories for new energy lithium battery station cabinets

What are the accessories for new energy lithium battery station cabinets

-

What are the outdoor communication battery cabinets in Kyiv

What are the outdoor communication battery cabinets in Kyiv

-

What are the new energy external battery cabinets included in

What are the new energy external battery cabinets included in

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.