1910.106

5 days ago · Automotive service station shall mean that portion of property where flammable liquids used as motor fuels are stored and dispensed from fixed equipment into the fuel tanks

Get Started

Eaton s lithium-ion UPS battery Q&A

Mar 21, 2025 · This document will serve as a guide for Eaton salespersons, sales support personnel, engineering clients, and end users who have questions regarding the lithium

Get Started

Storage of Flammable and Combustible Materials

6 days ago · According to the Fire Code, no more than 10 gallons of flammable solvents may be stored outside of flammable storage cabinets, and most labs/areas have limited cabinet space.

Get Started

Battery Rack | External Battery Racks | Battery

Jul 23, 2023 · Explore the best battery racks and cabinets for power system reliability. Learn how they help store, organize and secure batteries in

Get Started

Safe Lithium-Battery Cabinets for Secure Storage

Apr 6, 2025 · Protect your lithium-battery storage with Guangsheng Technology''s specialized cabinets. Designed for safety and durability, meeting global standards. Ideal for industries and

Get Started

Do Lithium Ion Batteries Require A Battery Room? Storage

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Get Started

What are the safety distance requirements for battery cabinets

CellBlock Battery Storage Cabinets are a superior solution for the safe storage of lithium-ion batteries and devices containing them. Skip to content 800-440-4119 [email protected] Search

Get Started

480.9 Battery Locations.

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for

Get Started

A Guide to Safely Storing Lithium Ion Batteries

Safety Storage offers lithium-ion battery stores and cabinets offer 90 minutes of fire protection with secure, lockable doors and self-sealing vents, which handle

Get Started

NFPA 30 and Safe Storage of Flammable Liquids

When the Occupational Safety and Health Administration (OSHA) created regulations governing the use, storage and handling of flammable liquids, they

Get Started

Complete Guide for Battery Enclosure

May 29, 2024 · Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

Get Started

Battery Room Safety & Installation Guide

Better is a distance of 10 mm to not reduce the service life of the battery by higher temperature or temperature differences between cells and blocks. The

Get Started

What is battery cabinet

Sep 26, 2023 · A battery cabinet is a device used for storing and managing batteries, which can be used in various fields, such as power systems,

Get Started

Battery Location Restrictions from AS/NZS

Jun 28, 2024 · The installation of Battery Energy Storage Systems (BESS) is governed by stringent safety standards as outlined in AS/NZS 5139:2019,

Get Started

Determining Safe Distances from Electrical Hazards

Having knowledge of when it is safe and what the appropriate boundaries are can help mitigate risk associate with electrical hazards. The elimination of risk will

Get Started

The Essential Guide to Energy Storage Building Distance: Safety

Ever wondered why your neighborhood battery farm isn''t right next to the playground? The concept of energy storage building distance is more than real estate logistics—it''s a cocktail of

Get Started

Clearance and creepage_UL-60950_IEC

Jan 24, 2018 · AC MAINS SUPPLY: a. power distribution system external to the equipment for supplying power to a.c. powered equipment These power sources include public or private

Get Started

How far from inverter can batteries be?

Feb 6, 2023 · If you need to share battery storage between two systems, your best bet would be to find some way of AC coupling between the two inverters, and send the juice between them

Get Started

The distance between energy storage containers

The physical distance between equipment is the most significant factor in how fire can spread within a BESS site, so maintaining adequate separation is crucial to minimising

Get Started

Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept

Get Started

Explosion-proof measures for battery cabinets during

Standards EN 62485-3:2014, applicable to traction batteries, and EN 62485-2:2018, applicable to stationary batteries, suggest keeping a so-called ''''safe distance'''' – a space around the battery

Get Started

Why you shouldn''t charge lithium-ion batteries

May 22, 2025 · Where can you safely charge your lithium-ion (bike) batteries? And why is a safety cabinet – also known as a flammable storage cabinet –

Get Started

Installation Procedure for UPS for External Batteries

NOTE: The distance between the modular battery cabinet (s) and the UPS must not exceed 100 m. Contact Schneider Electric for installations with a longer distance.

Get Started

EG4 BESS Spacing

Jan 31, 2025 · The minimum horizonal spacing requirement is 30 cm (12 inches) between two EG4-LL, EG4-LL-S and/or LifePower4 6 slot battery cabinet pairs as shown in Figure 2.

Get Started

Understanding the New PAS 63100:2024 Battery

While the guidelines recommend against installing batteries in lofts and similar spaces, some installations might still occur with appropriate safety measures

Get Started

Safety Clearance Recommendations for Electrical

Jun 21, 2015 · Clearance Tables includes working space and clearance around indoor electrical panel, Circuit Board (NES 312.2), clearance for conductor

Get Started

What is the appropriate safety distance between battery

measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wa

Get Started

Arc Flash Boundary Chart

May 1, 2018 · Arc Flash Boundary Chart defines safe approach distances per NFPA 70E. Learn how to identify boundaries and select proper PPE based on

Get Started

Article 480

Feb 28, 2021 · Storage Batteries Scope. This article applies to all stationary installations of storage batteries rmational Note: The following standards

Get Started

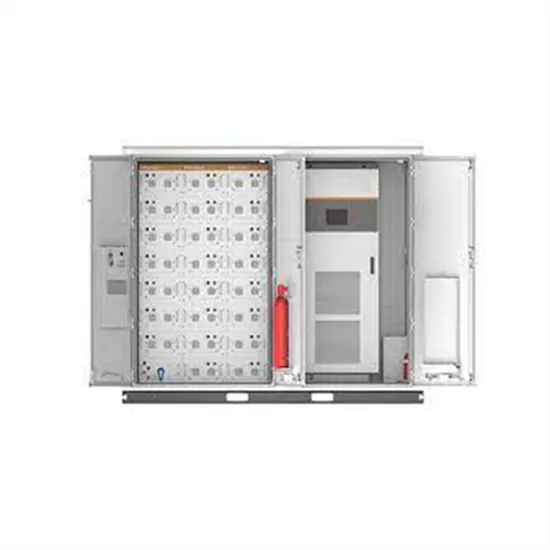

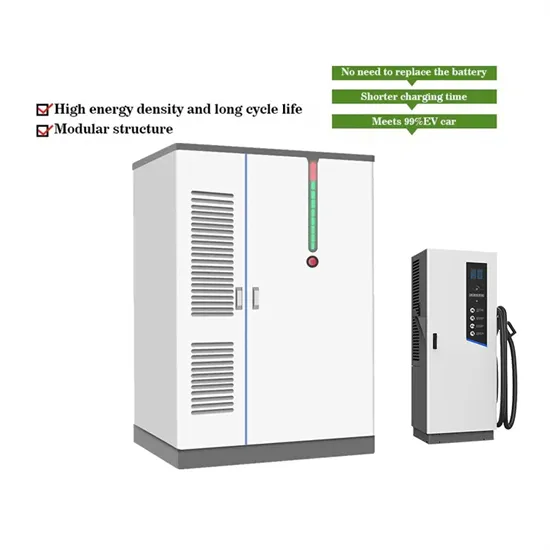

What is an energy storage battery cabinet?

May 22, 2024 · A comprehensive examination of an energy storage battery cabinet reveals that it serves as a vital component in modern energy

Get Started

What is a Battery Charging Cabinet? First time Buyer''s guide

Jun 13, 2025 · The numbers tell a sobering story. Over the past five years, failing lithium-ion batteries have caused more than 25,000 fire incidents globally. In the UK alone, lithium ion

Get Started

What is the best storage spacing for energy

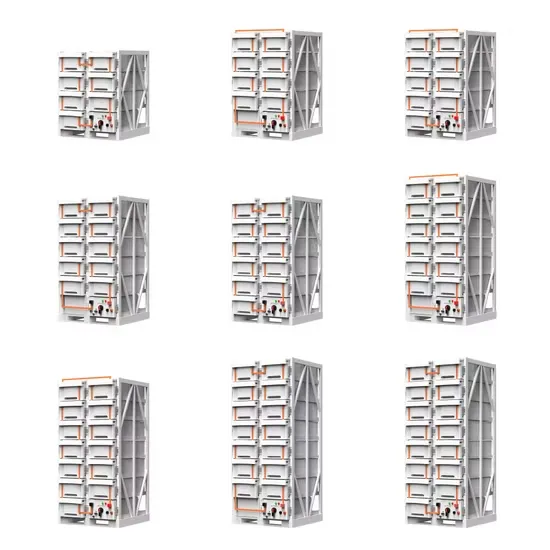

Jan 21, 2024 · The optimal storage spacing for energy storage cabinets is crucial for several reasons: 1) Proper airflow and heat dissipation are essential for

Get Started

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · A lithium ion battery cabinet should offer fire resistance from both the inside and outside. According to SS-EN-1363-1 testing standards, a

Get Started

6 FAQs about [What is the appropriate safety distance between battery cabinets ]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

How much space do you need for a battery system?

Spaces about battery systems shall comply with 110.26. Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

What are the requirements for a battery location?

Battery locations shall conform to 480.9 (A), (B), and (C). (A) Ventilation. Provisions appropriate to the battery technology shall be made for sufficient diffusion and ventilation of gases from the battery, if present, to prevent the accumulation of an explosive mixture. (B) Live Parts. Guarding of live parts shall comply with 110.27.

Are battery storage systems dangerous?

There has been a fair amount of news about battery storage systems being involved in fire and explosion incidents around the world. Do not forget that these are not the only safety issues when dealing with batteries. Battery systems pose unique electrical safety hazards.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

Related Articles

-

What are the domestic new energy battery cabinets

What are the domestic new energy battery cabinets

-

What are the manufacturers of rechargeable battery cabinets in Sri Lanka

What are the manufacturers of rechargeable battery cabinets in Sri Lanka

-

What are the types of uses of energy storage battery cabinets

What are the types of uses of energy storage battery cabinets

-

What batteries are lithium battery station cabinets made of

What batteries are lithium battery station cabinets made of

-

What are the technologies for making lithium battery station cabinets

What are the technologies for making lithium battery station cabinets

-

What are the wholesale manufacturers of outdoor communication battery cabinets in Asmara

What are the wholesale manufacturers of outdoor communication battery cabinets in Asmara

-

Spatial distance between battery cabinets

Spatial distance between battery cabinets

-

What are the outdoor communication battery cabinets in Kyiv

What are the outdoor communication battery cabinets in Kyiv

-

What battery cabinets are there in Cape Town EU

What battery cabinets are there in Cape Town EU

-

What are the materials used to produce battery cabinets

What are the materials used to produce battery cabinets

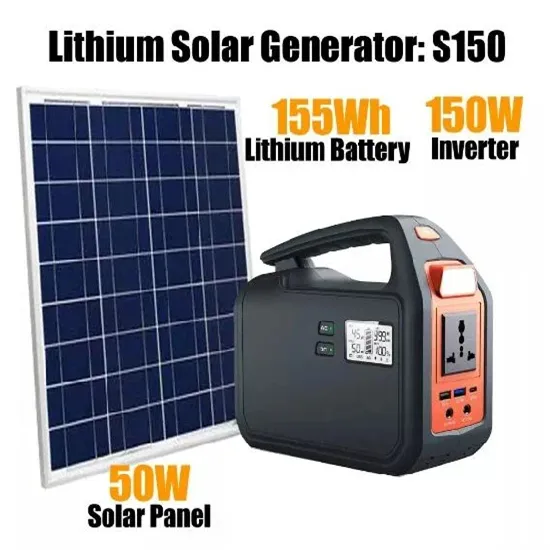

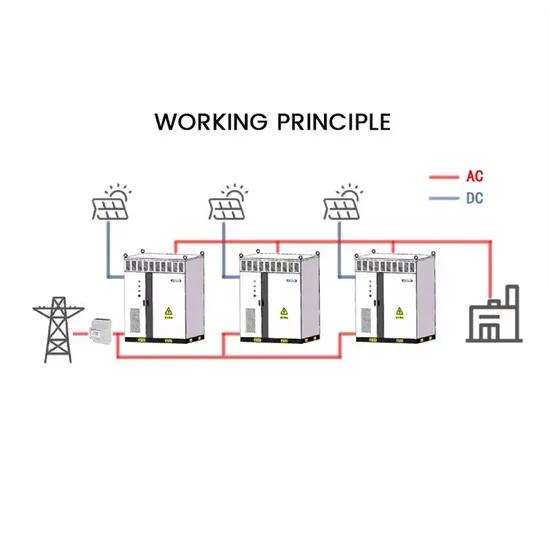

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.