Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · I. INTRODUCTION Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. Means used to perform cell

Get Started

What Is Lithium Battery Balancer?

Jun 6, 2024 · This blog introduces what a lithium battery balancer is, its importance, how it works and how to connect it with the battery packs.

Get Started

What is Cell Balancing for Lithium-ion Battery

Aug 7, 2024 · Learn about cell balancing for lithium-ion battery packs, its importance, methods, and benefits in ensuring optimal battery performance

Get Started

Active vs Passive Balancing: Which is Best for

Nov 1, 2024 · Do You Need Passive or Active Balancing for Your Lithium Battery? More people are interested in battery management systems (BMS). They want

Get Started

The Significance of Cell Balancing in Lithium Packs

Apr 25, 2024 · Cell balancing is a technique used to equalize the charge levels of individual cells within a lithium-ion battery pack. In a typical battery pack,

Get Started

Balanced capacity-based quantitative method for detecting

Jul 1, 2025 · Internal short circuits in lithium-ion batteries present a significant risk of thermal runaway. This study introduces a precise quantitative method for diagnosing internal short

Get Started

BU-803a: Cell Matching and Balancing

A battery expert once said: "I have not seen a cell balancing circuit that works." For multi-cell packs, he suggested using quality Li-ion cells that have been

Get Started

Battery Balancing: Techniques, Benefits, and How It Works

Learn how battery balancing improves performance, safety, and lifespan. Explore key techniques, benefits, and the science behind balancing battery cells effectively.

Get Started

Essential Guide to LiFePO4 Battery Balancing:

Apr 18, 2025 · Learn the importance of LiFePO4 battery balancing and discover the best methods to ensure your battery pack operates efficiently and safely.

Get Started

A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Get Started

Do Lithium Batteries Need to Be Balanced?-Vatrer

Nov 7, 2024 · Others Do Lithium Batteries Need to Be Balanced? Balancing is a critical aspect of lithium battery management, necessary for ensuring safe, efficient, and reliable operation. By

Get Started

A novel active lithium-ion cell balancing method based on

May 6, 2025 · In series and parallel strings connected Lithium-ion (Li-ion) battery modules or packs, it is essential to equalise each Li-ion cell to enhance the power delivery performance

Get Started

A complete analysis of lithium battery balancing

May 25, 2025 · Lithium battery balancing is a technology that eliminates or reduces the difference in power between individual cells in a battery pack by

Get Started

Active cell balancing of lithium‐ion battery pack based

Jan 16, 2024 · The shunting transistor ‐based balancing method is also only suitable for low ‐power battery packs due to the electrical energy consumption of the transistor.5,10Compared

Get Started

How To Balance A Lithium Batteries: Top and

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

Get Started

Battery Balancer Guide: Optimize Performance

Jul 25, 2024 · Battery balancing and battery balancers are crucial in optimizing multi-cell battery packs'' performance, longevity, and safety. This

Get Started

Everything You Need to Know About Battery Balancing

Apr 3, 2025 · Battery system balancing primarily ensures the safety of the energy storage system and then increases usable capacity. It is a maintenance and compensatory measure, with

Get Started

Active Balancing vs Passive Balancing

Jan 24, 2023 · Learn the differences between active and passive battery balancing so you can make an informed decision on which is best for your build.

Get Started

Battery pack balancing circuit based on LTC68021 lithium battery

1 Working principle of equalization circuit The battery pack balancing circuit designed in this paper based on the LTC68021 lithium battery pack management chip consists of four parts: power

Get Started

What is Battery Balancing and the Role of

Addressing these challenges requires advanced battery balancing strategies and robust management systems to optimize the performance and safety of lithium

Get Started

Battery Balancing: Techniques, Benefits, and How It Works

This article examines the concept of battery balancing, its significance, and methods for achieving effective battery balance. What Is Battery Balancing? Battery balancing is the process of

Get Started

A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · With the advancement of EV technologies, lithium-ion (Li-ion) battery technology has emerged as the most prominent electro-chemical battery in terms of high specific energy

Get Started

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. The means used to perform cell balancing

Get Started

Optimal Active Cell Balancing for Lithium-Ion Battery

Jun 22, 2025 · Abstract—This paper presents a novel two-stage optimiza-tion strategy to improve eficiency in active cell balancing for high-voltage lithium-ion battery packs. The proposed

Get Started

Analysis of Aging Effect and Cell Balancing Problem of

Mar 18, 2025 · Furthermore, the study addresses cell balancing challenges, essential for maintaining uniform cell voltages within battery packs to enhance performance and longevity.

Get Started

How to Achieve Battery Cell Balance with

Jun 4, 2024 · This blog introduce how to use LiFePO4 balancer in top balancing and bottom balancing to achieve LiFePO4 cell balance.

Get Started

What is cell balancing in a BMS and why is it

May 20, 2025 · Cell balancing refers to the process of equalizing the charge across all cells in an electric vehicle (EV) battery pack, ensuring each cell

Get Started

Analysis of Aging Effect and Cell Balancing

Mar 18, 2025 · This study presents an in-depth analysis of ageing and temperature effects in lithium-ion batteries, as well as an investigation into cell

Get Started

A multi-agent reinforcement learning approach for continuous battery

Jun 1, 2025 · Cell balancing in lithium-ion battery packs is essential for optimal performance, with active balancing offering advantages over passive balancing but requiring complex

Get Started

6 FAQs about [Balancing of lithium battery packs specifically refers to]

What is lithium battery cell balancing?

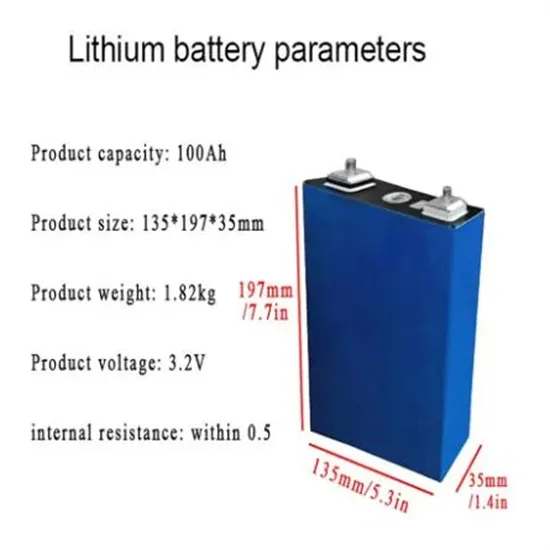

Lithium Battery Cell Balancing refers to the process of equalizing the state of charge (SoC) across all cells in a battery pack. This function is vital because even slight differences between cells can compound over time, leading to: When cells become significantly imbalanced, the entire battery pack’s performance is limited by the weakest cell.

Why is SoC balancing important in EV battery pack?

After performing cell balancing, each cell's SoC reaches 60 % (average SoC) which signifies that all cells have reached to same level or balanced. Therefore, SoC balancing is crucial in EV battery pack to increase the usable capacity. Fig. 3. Charge among five cells connected in series before and after SoC balancing.

What is a Li-ion battery pack?

The Li-ion battery pack is made up of cells that are connected in series and parallel to meet the voltage and power requirements of the EV system. Due to manufacturing irregularity and different operating conditions, each serially connected cell in the battery pack may get unequal voltage or state of charge (SoC).

Why is battery balancing important?

Due to manufacturing irregularity and different operating conditions, each serially connected cell in the battery pack may get unequal voltage or state of charge (SoC). Without proper cell balancing, serious safety risks such as over-charging and deep discharging in cells may occur.

What is a lithium battery control system?

A robust Lithium Battery Control System employs sophisticated balancing methods to mitigate these issues and maintain optimal pack health. Passive Cell Balancing represents the most widely implemented approach to maintaining cell equilibrium in lithium battery packs.

Can a simple battery balancing scheme reduce individual cell voltage stress?

Individual cell voltage stress has been reduced. This study presented a simple battery balancing scheme in which each cell requires only one switch and one inductor winding. Increase the overall reliability and safety of the individual cells. 6.1.

Related Articles

-

Lithium battery pack balancing time

Lithium battery pack balancing time

-

Castrie makes lithium battery packs

Castrie makes lithium battery packs

-

The more lithium battery packs are connected in parallel

The more lithium battery packs are connected in parallel

-

How many A are 21 strings of 72V lithium battery packs

How many A are 21 strings of 72V lithium battery packs

-

Can 12v lithium battery packs be used in parallel

Can 12v lithium battery packs be used in parallel

-

What companies in Colon Panama use lithium battery packs

What companies in Colon Panama use lithium battery packs

-

Tax rate for producing lithium battery packs

Tax rate for producing lithium battery packs

-

How many strings of lithium iron phosphate battery packs

How many strings of lithium iron phosphate battery packs

-

Is it good to work on lithium battery packs

Is it good to work on lithium battery packs

-

4 lithium iron phosphate battery packs

4 lithium iron phosphate battery packs

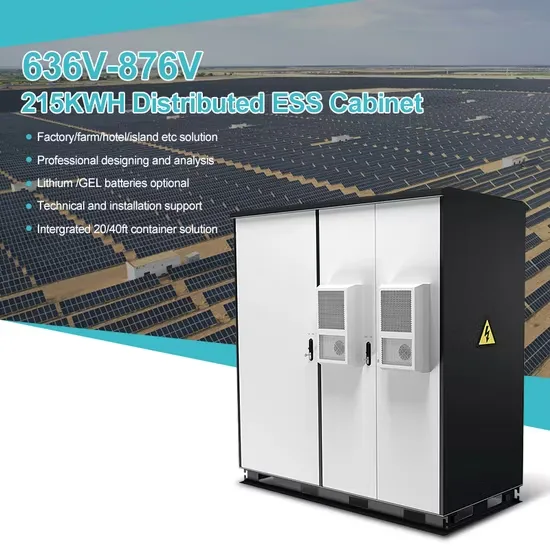

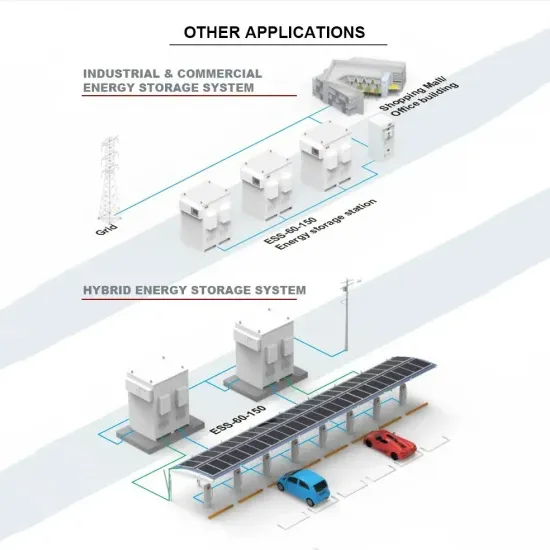

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

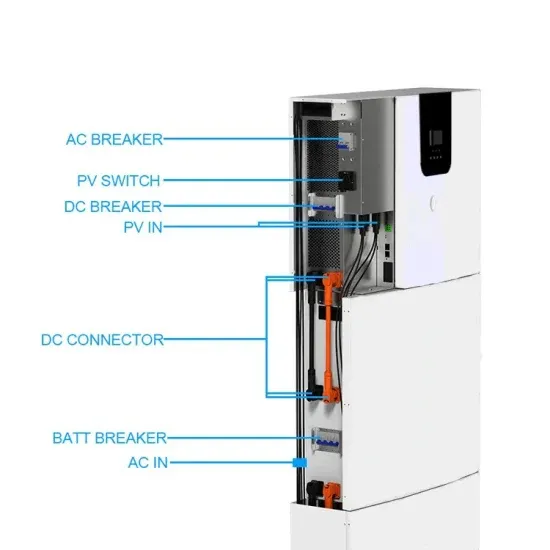

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.