Wind Turbine Gearbox Lubrication: Performance,

Mar 5, 2021 · Wind Turbines Windpower Intelligence (WPI) research is based on country pipelines of announced wind farms (>5 MW) that are at various stages of development, and estimated to

Get Started

ACTIVE AND PASSIVE SYSTEMS FOR WIND TURBINES

Jun 11, 2024 · Enhanced heat transfer: The phase change of the work-ing fluid enables more efficient heat transfer compared to traditional liquid cooled loops, allowing loop thermosyphons

Get Started

Preparation and characterization of phase change material

May 7, 2024 · In order to improve the effect of liquid cooling system for wind turbine, this study used ultrasonic preparation method, stearic acid as phase change material, sorbitan trioleate

Get Started

cooL systEm, Hot REsuLts

Aug 31, 2022 · cooL systEm, Hot REsuLts New cooling system from Parker provides significant advantages to wind turbines by offering greater performance in a smaller package.

Get Started

Preparation of n-Tetradecane Phase Change

May 19, 2024 · After mixing tetradecane phase change microcapsules (PCMS) with polyurethane coating (PUR) and coating them on wind turbine blades,

Get Started

Thermodynamic Performance Analysis and Multi

Aug 8, 2025 · Against the backdrop of global energy transition, the continuous growth in both the installed capacity of wind farms and the power rating of individual turbines has made efficient

Get Started

CN219980597U

The utility model provides a phase transition cooling system suitable for doubly-fed wind generating set which characterized in that: the outlet of the main circulating pump (1) is

Get Started

Wind Turbine Cooling Systems Market

Apr 21, 2025 · Phase-change material (PCM)-based cooling systems, which absorb excess heat during load fluctuations, have extended power converter lifetimes by 3–5 years in Chilean

Get Started

Recent research advances in wind turbine thermal

However, the progress in the research on cooling methods for wind power generation systems has been slow, resulting in the current cooling technology being unable to completely solve the

Get Started

Recent research advances in wind turbine thermal

Feb 1, 2025 · By detecting the temperature of the components to control both the start and stop of the cooling system as well as the size of the cooling power, the aim is to reduce the energy

Get Started

Cooling in wind turbines

Sep 28, 2021 · A large part of the energy consumption in wind turbines is cooling, so Rosenberg fans are designed to be 100% adapted to each project.

Get Started

Wind Turbine Cooling Systems | Heatex

Aug 12, 2025 · Maximize wind turbine performance with Heatex''s complete and customizable cooling systems for generator, nacelle and converter/

Get Started

Wind Turbine Thermal Management | Maximize Efficiency

Jun 2, 2025 · ACT''s advanced cooling solutions—high-performance Loop Thermosyphons and high-capacity Pumped Two-Phase systems—efficiently manage heat within wind turbines.

Get Started

Preparation and characterization of phase change material

Jul 1, 2024 · In this study, we successfully prepared a phase change material emulsion suitable for use as a cooling medium in wind turbine liquid cooling systems. Through an ultrasonic

Get Started

Transpiration cooling with phase change by functionally

May 15, 2023 · Transpiration cooling has been investigated in numerous applications, such as a rocket combustor [2], nose cone of a flight vehicle [3], strut injector for a scramjet engine [4],

Get Started

Preparation and characterization of phase change material

8–14% SA-PCMEs have been prepared and characterized. The liquid cooling effect of SA-PCMEs in wind turbines has been explored. Research speed, flow rate, inlet temperature on PCMEs

Get Started

Design and research of cooling system for 2.5 MW permanent magnet wind

May 1, 2021 · The 2.5 MW direct-drive permanent magnet wind turbine cooling system uses forced air cooling, and the heat exchanger of the cooling system does not exchange gas, but

Get Started

Custom Cooling Systems for Rolling Stock

Cooling Systems for Wind Power: Onshore and Offshore AKG in Wind Power: Cooling Solutions for a Greener Future At AKG, we are proud to be a trusted

Get Started

Stress Management of Wind Turbine Components Using a

Jun 26, 2025 · Abstract: Offshore wind turbine components endure high mechanical and thermal stress due to fluctuating wind conditions and harsh marine environments, but lack coordinated

Get Started

Preparation and characterization of phase change material

May 7, 2024 · Preparation and characterization of phase change material emulsions and their applications in liquid cooling systems for wind turbines,Applied Thermal Engineering - X-MOL

Get Started

Industry Developments: Cooling Electronics in

Dec 21, 2016 · But most of today''s wind turbine industry is for utility-scale power generation. These are large, tall wind turbines, in fields of dozens or hundreds,

Get Started

Development, components & service for wind

Development, components, systems and service for all wind turbines Wind power expertise from a single source From generators to gearboxes to power cables:

Get Started

Failure Analysis and Diagnosis of Wind Turbine Evaporative Cooling System

Jan 7, 2025 · This paper aims to study the high temperature faults that frequently occur during the operation of evaporative cooling wind turbine, analyze the root causes of the faults according

Get Started

Review of the Cooling Technology for High-power Wind

In foreign, the introduction of high-power wind turbines are rarely reported due to technical protection. The present situation of cooling technology for wind turbine are summarized, and

Get Started

Study on Phase-Change Cooling for A Reactor Used in Offshore Wind

Nov 29, 2024 · Effectively addressing the cooling issue is essential for further improving the power density of the reactor. Based on the structure and cooling characteristics

Get Started

Two phase flow evaporative cooling technology for wind turbine

May 13, 2024 · This article combines a new type of pump driven two-phase flow cooling system with the heat dissipation system of wind turbines, compares wind turbines using two-phase

Get Started

Recent research advances in wind turbine thermal

Feb 1, 2025 · However, the progress in the research on cooling methods for wind power generation systems has been slow, resulting in the current cooling technology being unable to

Get Started

CN115460858A

May 2, 2023 · The invention discloses a phase change cooling system for a converter of a wind power generating set. The phase change heat dissipation system of the wind turbine converter

Get Started

Preparation and characterization of phase change material

The liquid cooling effect of SA-PCMEs in wind turbines has been explored. Research speed, flow rate, inlet temperature on PCMEs liquid-cooled systems. Energy utilization efficiency of PCME

Get Started

Preparation and characterization of phase change material

May 7, 2024 · Article on Preparation and characterization of phase change material emulsions and their applications in liquid cooling systems for wind turbines, published in Applied Thermal

Get Started

Temperature Control in Wind Turbine Systems

Aug 11, 2025 · Explore recent advancements in thermal management technologies used in wind turbines, ensuring optimal performance, efficiency,

Get Started

WIND TURBINE COOLING: THE STATE-OF-THE-ART

Sep 22, 2017 · In order to ensure the secure and stable operation of wind turbine, effective cooling systems has to be implemented to these components. Since the early wind turbines

Get Started

White Paper

Aug 31, 2022 · White Paper Cooling High Performance Wind Turbine Systems With Two-Phase Evaporative Cooling Background Wind turbine capacity, particularly for offshore turbines,

Get Started

Wind Turbine Thermal Management | Maximize Efficiency

Jun 2, 2025 · ACT''s Advanced Cooling Solutions for Wind Turbines ACT''s advanced cooling solutions—high-performance Loop Thermosyphons and high-capacity Pumped Two-Phase

Get Started

Investigation of water phase change rotating cooling for

Mar 1, 2024 · In order to increase turbine inlet temperature, water phase change rotating cooling scheme for turbine was proposed for using the gasification latent heat to improve cooling

Get Started

Cooling Techniques in Direct-Drive Generators

Aug 18, 2022 · Direct-drive generators are an attractive candidate for wind power application since they do not need a gearbox, thus increasing operational

Get Started

6 FAQs about [Phase change cooling system for wind turbine]

How to cool a wind turbine?

Through the years challenges of cooling systems for wind turbine caused the new cooling systems. A simple way to cooling the turbine is using the small part of inlet air to the nacelle and filling the needed part and finally exhausting the air from nacelle . These days in MW wind turbines use oil or water for cooling.

How wind turbine cooling system works?

As previously described enough wasted heat produce in wind turbine especially in MW turbine. In this study, a conceptual design of a new wind turbine cooling system is proposed. In this system, the heat which is generated by wind turbine using a coolant comes to ORC cycle and gives the heat into the refrigerant.

What are heat transfer techniques in wind power systems?

As a result, research has steadily been done on the thermal behavior and temperature fields of wind power systems. Heat convection, heat radiation, and heat conduction are the three most significant heat transfer techniques .

What are the different types of wind turbine cooling?

Wind turbine cooling is divided two categories air and liquid cooling. The air cooling part includes both natural and force cooling. About 95% if the wind turbine cooling is done by forced air and liquid cooling . There are many types of cooling technologies includes: air-air, liquid-air, air-liquid-air, liquid-liquid-air, air-liquid-liquid.

Can a 750 kW wind turbine be cooled?

As to large- and medium-scale wind generating set with power more than 750 kW, a liquid recirculation cooling method can be implemented to satisfy the cooling requirement . Regarding MW wind turbine with a larger power capacity, the gearbox, generator and control converter all produce comparatively large amount of heat .

What is waste heat in a wind turbine?

Generally, every large wind turbine has a cooling system and a lubrication heater. So, for ensuring normal operation heat exchange rate between gearbox and cooling fluid must be sufficient. The next section of waste heat is generator rotor. The generator rotor is connected to gearbox and rotate in high speed.

Related Articles

-

Large-scale phase change energy storage

Large-scale phase change energy storage

-

How to change the power supply of battery cabinet to wind power

How to change the power supply of battery cabinet to wind power

-

Wind turbine 12v directly connected to inverter

Wind turbine 12v directly connected to inverter

-

Niamey phase change energy storage products

Niamey phase change energy storage products

-

Maldives Phase Change Energy Storage System

Maldives Phase Change Energy Storage System

-

Democratic Congo phase change energy storage system supplier

Democratic Congo phase change energy storage system supplier

-

Grid-connected wind turbine control system

Grid-connected wind turbine control system

-

Constant frequency system and wind turbine

Constant frequency system and wind turbine

-

Wind turbine AC system

Wind turbine AC system

-

Wind turbine fire control system

Wind turbine fire control system

Commercial & Industrial Solar Storage Market Growth

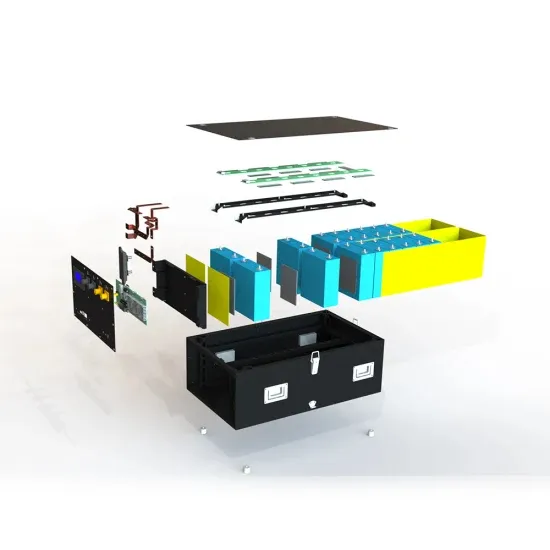

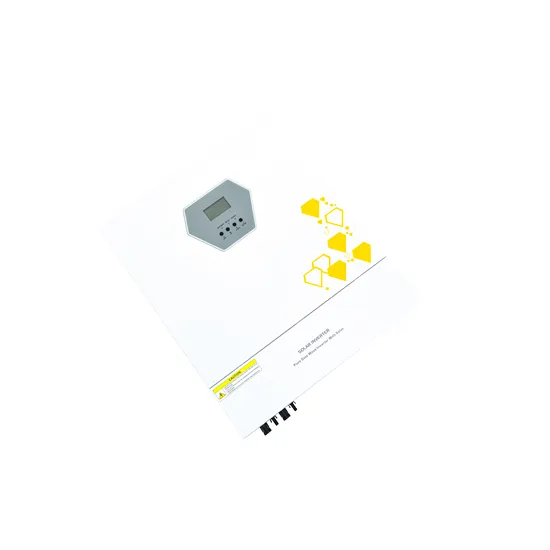

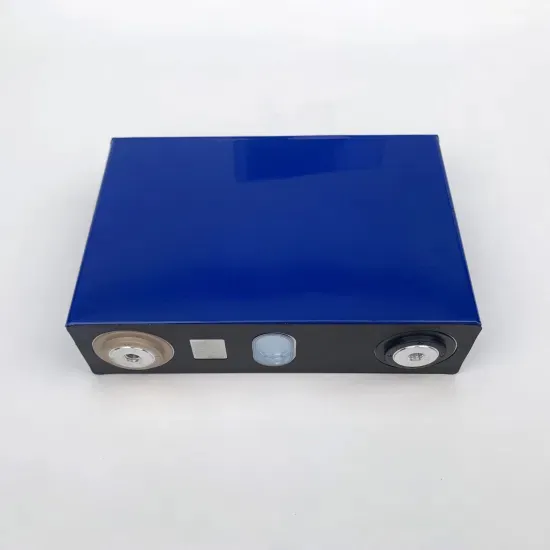

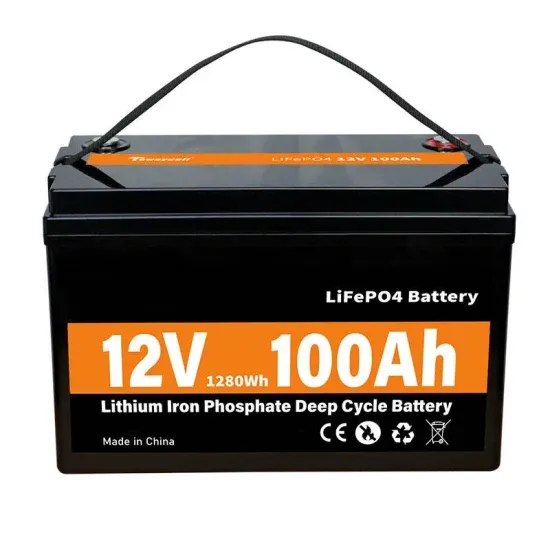

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.