1 Wind Turbine Control

Feb 12, 2016 · The control system on a wind turbine is designed to: seek the highest e ciency of operation that maximizes the coe cient of power, Cp,

Get Started

Fuzzy self-adaptive PID control of the variable speed constant

Jul 13, 2014 · The variable-pitch system is one of the most active subject in the wind turbine control field. After analyzing the principle of variable-pitch wind turbine, the modeling of

Get Started

A review on frequency support provision by wind power

Jan 1, 2018 · The continuing increase of wind energy penetration into power systems, in combination with the retirement of conventional generation, raises new challenges for the

Get Started

Wind Turbine Frequency Control in Power

Oct 22, 2024 · Explore how primary frequency control in wind turbines ensures grid stability, synchronicity, and reliability in clean energy systems.

Get Started

Research on fault detection and remote monitoring system

Jan 1, 2024 · In order to study the operating characteristics of variable speed constant frequency wind turbine under different working conditions and the monitoring system of wind turbine. In

Get Started

The History and State of the Art of Variable-Speed Wind

Aug 12, 2013 · However, if a wind turbine is connected to a power grid through appropriate electronic power processing modules, not only will the grid be supplied with power at constant

Get Started

Research on fault detection and remote monitoring system

Dec 1, 2023 · In order to study the operating characteristics of variable speed constant frequency wind turbine under different working conditions and the monitoring system of wind turbine. In

Get Started

Constant Speed Wind Turbine

13.2 CONSTANT SPEED WIND TURBINES The majority of the presently installed wind turbines operate at constant (or near constant) speed. This implies that regardless of the wind speed,

Get Started

Constant speed and constant frequency wind

Download scientific diagram | Constant speed and constant frequency wind turbine from publication: Impact Analysis of Increased Penetration of Variable

Get Started

Maximum power point tracking algorithms for

Oct 8, 2022 · Wind energy is one of the most important clean energies and the variable speed constant frequency technology is widely used in wind energy

Get Started

Research on fault detection and remote

Dec 1, 2023 · In order to study the operating characteristics of variable speed constant frequency wind turbine under different working conditions and the

Get Started

Modeling and Control of a 600 kW Closed

In this paper, an innovative closed hydraulic wind turbine with an energy storage system is proposed. The hydraulic wind turbine consists of the wind rotor, the

Get Started

Frequency response methods for grid-connected wind

Aug 1, 2023 · The increasing penetration of wind power leads to a decrease in the proportion of synchronous generators, which weakens the frequency response (FR) ability of the power

Get Started

Improvements of an IG Wind Turbine System with Constant

Nov 6, 2024 · This paper introduces a novel approach for the fixed-switching frequency of a wind turbine-based induction generator in microgrid. The proposed strategy combines power control

Get Started

An Optimal Fast Frequency Control Method for Variable Speed Wind

Feb 4, 2025 · This research presents a proposal to enhance the system frequency by utilizing WFs and restoring the speed of the wind turbine (WT) rotor using the doubly fed induction

Get Started

A two-stage frequency response method for DFIGs under variable wind

Dec 1, 2023 · With the increasing risk of grid frequency stability, it has become a consensus that DFIGs should participate in the frequency response process to improve the frequency

Get Started

Wind Turbine Frequency Control in Power

Oct 22, 2024 · Primary frequency control (PFC), an integral component of wind turbine operation synchronous with the grid and maintaining stability and

Get Started

Variable speed and constant frequency control of

Dec 11, 2016 · Silva et al. has established the mathematical models of the wind turbine with different drive trains, includ-ing the conventional gearbox, direct-drive layout and advanced

Get Started

Inertia-based Fast Frequency Response from Wind

Sep 9, 2021 · Inertia-based Fast Frequency Response from Wind Turbines Power system balancing and operation with large shares of wind power workshop EU Marie Curie WinGrid

Get Started

Frequency support with wind turbines

Aug 14, 2025 · Deloading control for wind turbines can ensure a power reserve for participation in frequency regulation. This study presents the design of a constant deloading control technique

Get Started

Numerical simulation and experimental study of

Sep 25, 2018 · The variable speed and constant frequency wind turbine with differential speed regulation consist of wind rotor, speed regulating motor,

Get Started

Understanding Inertial and Frequency Response of Wind

Oct 2, 2013 · We will demonstrate practical approaches to allow variable slip and speed wind turbines to contribute inertia to the host power system grid. The approaches are based on the

Get Started

Wind Turbine Control Systems: Current Status and

Apr 5, 2009 · Wind Turbine Power Production Two important non‐dimensional numbers: Tip Speed Ratio Power Coefficient Tip speed ratio To maximize power output, want constant

Get Started

Variable speed and constant frequency control

Aug 3, 2017 · Ultimately, simulations under the two conditions of step and sine wind wheel speeds are done. The simulation results demonstrate how the

Get Started

IMPACTS OF WIND (AND SOLAR) POWER ON POWER

Aug 11, 2021 · Synchronous power system – operates at close to a constant frequency (50 or 60 Hz). Conventional generators, due to their rotating masses, provide inertial support and tend to

Get Started

a Variable Speed, Constant Frequency Generating System

Aug 6, 2020 · sisted of operating the VSCF system on a wind turbine. This paper will cover phase two in some de that it can improve the operations of a wind turbine. Improves in this case,

Get Started

(PDF) Frequency Control and Wind Turbine

Dec 1, 2005 · Regardless of wind turbine technology, the displacement of conventional generation with wind will result in increased rates of change of

Get Started

Inertial and primary frequency response model

Nov 17, 2017 · Abstract Increase of converter-connected renewable power generation such as variable-speed wind turbines (VSWTs) decreases the

Get Started

Research on Idle Load Grid-Connected Control Strategy of

Sep 23, 2024 · This paper focuses on the modeling and simulation of a variable speed constant frequency doubly-fed wind turbine system. The research encompasses the development of a

Get Started

Development of constant switching frequency model

Apr 1, 2024 · The proposed control method and the entire system under study, consisting of a wind turbine, DFIG, back-to-back VSCs, BESS, a three-phase grid, and the loads, are

Get Started

A Review on Different Pitch Angle Control Methods for

Nov 21, 2016 · Abstract - This paper summarizes current research and applications of wind turbine individual pitch control, reviews the basic concepts and working principles of individual

Get Started

Research on Idle Load Grid-Connected Control Strategy of

Sep 23, 2024 · The doubly-fed wind turbine, recognized for its wide operational speed range, high energy utilization rate, soft grid connection, and adjustable power factor, represents a

Get Started

Grid-connection of variable-speed and constant

Jan 6, 2022 · The variable speed constant frequency wind power generation system of the synchronous generator is shown in Figure 1. In the figure, P W

Get Started

Current status and future prospects of continuously variable speed wind

Apr 1, 2019 · However, the direct connections of power electronics to a constant-frequency grid always result in a mismatch of torque-speed characteristics between the turbine system load

Get Started

Variable speed and constant frequency control of hydraulic wind turbine

Aug 3, 2017 · Abstract To eliminate the adverse effect of the fluctuation and intermittence of wind power on the quality and stability of electrical power system, an energy storage system is

Get Started

6 FAQs about [Constant frequency system and wind turbine]

How does a constant speed wind turbine work?

A constant speed wind turbine operates at the maximum power point according to the wind conditions to control the active and reactive power of the machine. This is achieved through power electronics for machine control. The turbine may include a synchronous or induction generator.

How do wind turbines control rotary speed and grid frequency?

In constant speed wind turbines, the control system decouples the rotary speed and grid frequency. This means that the wind turbines cannot provide corresponding active power when grid frequency varies, reducing the inertia of the whole power grid.

How does a variable speed wind turbine operate?

In a variable speed wind turbine, the rotor speed increases with wind speed up to a certain limit. This allows for quieter operation at low wind speeds compared to a constant speed wind turbine.

How do wind turbines control primary frequency?

The primary frequency control by wind turbines can be integrated into the rotor-side active power control loop and demonstrate behavior similar to conventional synchronous generators. The wind turbine must operate in curtailed mode to provide reserve for primary response when frequency drops.

How is a wind turbine controlled?

The conventional control of a wind turbine involves regulating the power yield and rotor speed. In above-rated wind conditions, the generator power should be as close as possible to the rated value. In below-rated wind speeds, the rotor speed should 'track' the wind speed to gain maximum energy yield.

What algorithm is used for constant speed wind turbines?

For constant speed wind turbines, the FFT algorithm is directly applied to the measured acceleration time signals a ( t ) to analyse periodic nacelle oscillations. To analyse nacelle oscillations of variable speed wind turbines, a modified algorithm has to be used which is called order analysis.

Related Articles

-

Communication base station wind and solar complementary ring frequency work

Communication base station wind and solar complementary ring frequency work

-

Wind turbine mechanical brake system

Wind turbine mechanical brake system

-

Wind turbine PLC main system control

Wind turbine PLC main system control

-

Micro power station wind turbine

Micro power station wind turbine

-

Components of wind turbine cabinet in communication base station

Components of wind turbine cabinet in communication base station

-

Wind turbine 12v directly connected to inverter

Wind turbine 12v directly connected to inverter

-

Wind turbine communication system

Wind turbine communication system

-

Tampere three-phase wind power generation system in Finland

Tampere three-phase wind power generation system in Finland

-

Typical system structure of wind power generation

Typical system structure of wind power generation

-

Huawei s wind power storage

Huawei s wind power storage

Commercial & Industrial Solar Storage Market Growth

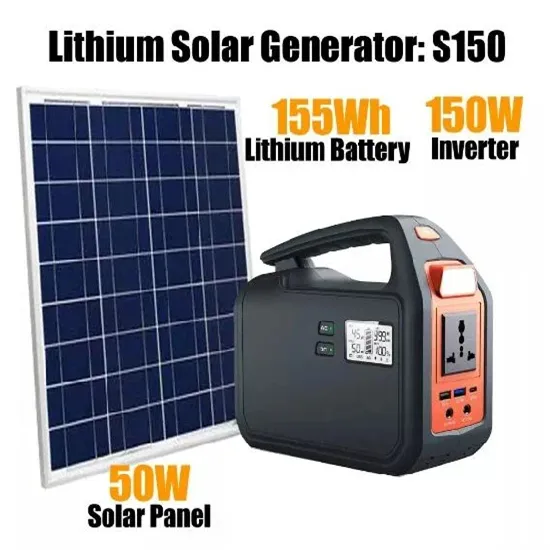

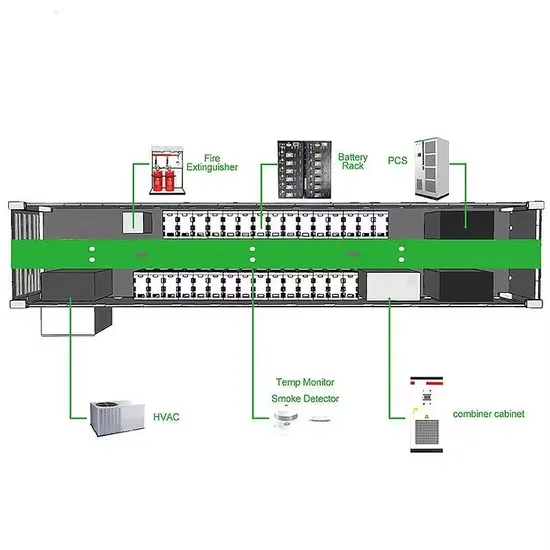

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

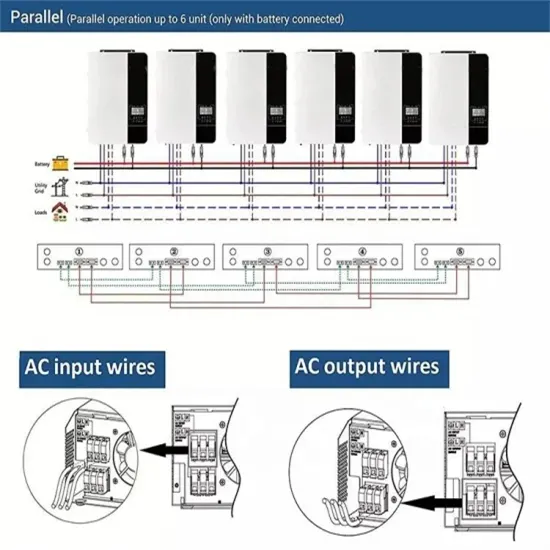

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.