Wind Turbine System

The main operating parts of a wind turbine generator system (WTGS) are turbine, nacelle, and tower; the nacelle consists of a generator, the mechanical gearing, wind and speed sensors, a

Get Started

Control of Wind Turbines | IEEE Journals & Magazine | IEEE

Mar 14, 2011 · Wind energy is a fast-growing interdisciplinary field that encompasses multiple branches of engineering and science. Despite the growth in the installed capacity of wind

Get Started

LicOS PLC for Wind Power Turbine Control and Operational

These solutions cover critical wind turbine systems, including pitch control, yaw control, nacelle systems, and ground control systems. With a focus on intelligence, safety, and reliability, our

Get Started

基于S7-1200的风力发电机组控制系统

收起 With S7-1200 PLC as the main controller, a variable-pitch and constant-speed wind turbine control system is designed. The system hardware structure is introduced. The control

Get Started

PLCs can improve wind turbine performance

Feb 4, 2016 · Inside Machines: Installing non-OEM programmable logic controllers (PLCs) on wind turbines improves performance and reduces

Get Started

Wind turbine control design | Wind Energy Modeling and

Jul 3, 2024 · In this chapter, the author introduced wind turbine control, discussing sensors and actuators, operating regions, and the operational controller loops. The author then described

Get Started

Wind Power Plants Control Systems Based on SCADA System

Mar 5, 2021 · For this, the combined wind turbine frequency transformer, external loop control system (PLC), and factory management system (PCC) together should influence the wind

Get Started

Dedicated

Dec 16, 2024 · Fast, reliable real-time control with multiple control functionalities VestasOnline® Power Plant Controller (PPC) controls the output of the wind power plant at the point of

Get Started

Control of Large Wind Energy Systems Throughout the

Oct 14, 2024 · This contribution examines the control problem for very large wind energy converters during shutdown operation and analyses the most important control approaches.

Get Started

PLC Hardware-in-the-Loop Simulation of Wind Turbine

Dec 3, 2023 · This paper introduces the new achievements of wind turbine modeling and master controller hardware-in-the-loop simulation based on the panoramic co-simulation a

Get Started

Development of Wind Turbine Blade Pitch Controller

May 6, 2025 · Wind energy isa having continual to show a major role as most widely used green-energy source. But, a Wind Turbine (WT) system''s efficacy level and cost effectiveness with

Get Started

Research and application of main control system for 2MW

Oct 16, 2023 · The proposed control system is designed based on PLC and applied to a real 2MW wind turbine on a wind farm in Shandong Province. The proposed study is able to provide

Get Started

PC-based Control for Wind Turbines

Aug 10, 2025 · The Wind Compendium 2022, a special edition of our PC Control customer magazine, is a collection of selected application reports about wind power which have been

Get Started

Advanced wind turbine protection and control system

Jul 25, 2025 · Protection and Control The W650 Wind Generator Protection System has been designed as a comprehensive generator protection and control device specially developed for

Get Started

ABB Wind power generation

The turbine control and protection system ensures that the turbine''s operation is within defined values. The PLC (Programmable Logic Controller) is used for

Get Started

Main controller

The main controller is the brain of the turbine, taking care of overall decisions, control, monitoring and communication. While the main component is the PLC, several low voltage products are

Get Started

PLC Hardware-in-the-Loop Simulation of Wind Turbine

Dec 3, 2023 · This paper introduces the new achievements of wind turbine modeling and master controller hardware-in-the-loop simulation based on the panoramic co-simulation architecture.

Get Started

Wind turbine control systems and techniques

Jan 1, 2011 · The main control loops, called here conventional wind turbine control, concern the regulation of the power production and rotor speed control. Power control is achieved by both

Get Started

Wind Turbine Control Systems Explained: Driving Renewable

Jan 28, 2025 · Australian Control Engineering Pty LtdDiscover how to enhance wind turbine through control systems, by optimizing blade pitch, speed regulation, and energy efficiency.

Get Started

An overview of control techniques for wind turbine systems

Nov 1, 2020 · This review paper presents a detailed review of the various operational control strategies of WTs, the stall control of WTs and the role of power electronics in wind system

Get Started

Research and application of main control system for 2MW

Oct 16, 2023 · A main control system is proposed to achieve safe and stable operation for PMSG-based wind turbines, employing a consistent concept for overall top-level design and sub

Get Started

PLC in Renewable Energy

Another control strategy utilized in renewable energy systems is pitch control, which adjusts the blade angle of a wind turbine to maintain a constant rotor speed.

Get Started

Improving wind-turbine performance with PLCs

Dec 5, 2016 · Based on this assessment, engineers replaced the wind measurement mechanical sensors with a single ultrasonic sensor (see image,

Get Started

Wind Power Plants Control Systems Based on

Mar 5, 2021 · The objective of this chapter is to introduce the state of the art technology in wind power plant control and automation. This chapter starts

Get Started

Advanced Control Design for Wind Turbines; Part I:

Sep 30, 2013 · The purpose of this report is to give wind turbine engineers information about designing, implementing, and testing advanced control systems for wind turbines. We want to

Get Started

Improving wind-turbine performance with PLCs

Dec 5, 2016 · The turbine control system adjusts blade pitch and rotor speed differently depending on the degree of turbulence. It does so to protect the

Get Started

Programmable Logic Controllers | Wind Turbine Technician

Mar 6, 2025 · This module provides a general overview of PLCs and their application in wind turbines. An introduction to ladder logic is presented and the most common types of PLC

Get Started

Wind turbine main control system and method based on PLC

Dec 5, 2024 · The wind turbine main control system based on PLC comprises: a wind turbine power generation capacity assessment module, a wind turbine power generation task

Get Started

CONTROL OF WIND TURBINES

Feb 22, 2023 · Wind turbines have to also be oriented perpendicular to the wind stream using wind orientation mechanism or yaw control. In addition their brakes must be applied under

Get Started

Analysis of PLC technology in the application of

Jul 1, 2024 · In the wind power control system, PLC controller becomes the main control means with its stable, efficient and easy maintenance characteristics.

Get Started

Wind turbine control system design

The control system is the nerve centre of a wind turbine, managing each component to ensure safe and optimized operation. As turbines get larger and more complex, so must their control

Get Started

Mechatronics

The present manual includes four Job Sheets that introduce students to PLC control of the Wind Turbine Training System, Model 8075-5. Throughout the manual, students will learn how to

Get Started

Main controller: industry-leading connectivity

Designed to meet the requirements in wind turbines and renewable energy application, our controller combines long lifetime and stable operation with

Get Started

Internet based monitoring and control of a wind

Apr 1, 2015 · Due to structure of a wind turbine, they must be established on a wide area. In order to monitor and control wind turbines, which are under

Get Started

6 FAQs about [Wind turbine PLC main system control]

What is plc controller in wind power control system?

In the wind power control system, PLC controller becomes the main control means with its stable, efficient and easy maintenance characteristics. At present, there are many kinds of new energy exploitation technologies all over the world, and wind power generation technology is one of the more mature technologies.

How can plc help a wind power system?

In addition, PLC can also implement remote troubleshooting and diagnosis of the wind turbine to improve the reliability of the system and the efficiency of protection.PLC can realise remote monitoring and management of the wind power system by connecting with the remote monitoring system.

What is a turbine controller?

The main controller is the brain of the turbine, taking care of overall decisions, control, monitoring and communication. While the main component is the PLC, several low voltage products are necessary around it, mostly for power supply, protection and communication.

What is a Wind Power plc soft redundancy system?

In conclusion, the wind power PLC soft redundancy system improves the reliability and stability of the system by using multiple PLC controllers and realising automatic switching. When the main controller fails, the standby controller can immediately take over control to ensure the normal operation of the wind turbine.

What is a wind power control system?

In summary, the wind power control system maximises power generation efficiency and stability by monitoring and adjusting the operating parameters and status of the wind turbine in real time. The working principle of this automated control system provides important support for the reliable operation and development of the wind power industry.

What is a cm60 wind turbine controller?

The controller is designed to tolerate the high levels of vibration and EMC disturbances in a wind turbine. The CM60 represents more than a standard PLC. It contains a powerful software framework, designed especially for wind turbine applications. With its standard interfaces it combines high flexibility with great power.

Related Articles

-

Grid-connected wind turbine control system

Grid-connected wind turbine control system

-

Wind turbine fire control system

Wind turbine fire control system

-

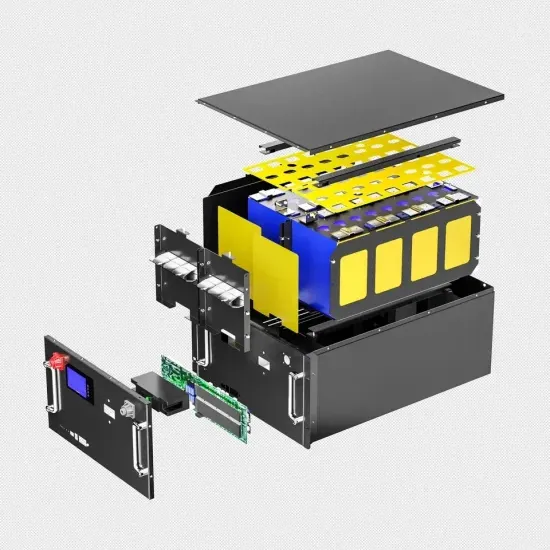

Energy storage battery management system main control module

Energy storage battery management system main control module

-

Wind turbine communication system

Wind turbine communication system

-

How many mobile energy storage sites and wind power does Ashgabat control

How many mobile energy storage sites and wind power does Ashgabat control

-

Vertical Axis Wind Turbine Power System

Vertical Axis Wind Turbine Power System

-

Phase change cooling system for wind turbine

Phase change cooling system for wind turbine

-

Intelligent control system for wind power generation

Intelligent control system for wind power generation

-

Constant frequency system and wind turbine

Constant frequency system and wind turbine

-

Construction of communication base station wind power station cabinet

Construction of communication base station wind power station cabinet

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.