A Review of Flywheel Energy Storage System

Mar 16, 2017 · Energy storage systems (ESS) provide a means for improving the efficiency of electrical systems when there are imbalances between supply

Get Started

Introduction

Feb 26, 2023 · Modern flywheel batteries are often used in long-term energy storage solutions and are usually highly massive to optimize energy loss thanks to their high moment of inertia.

Get Started

Flywheel energy storage systems: A critical

Jul 19, 2021 · However, being one of the oldest ESS, the flywheel ESS (FESS) has acquired the tendency to raise itself among others being eco-friendly and

Get Started

An AMB Energy Storage Flywheel for Industrial

Mar 30, 2020 · 1. BACKGROUND A flywheel energy storage system has been developed for industrial applications. The flywheel based storage system is targeted for some applications

Get Started

What is Flywheel Energy Storage? | Linquip

Apr 4, 2023 · A flywheel energy storage system employed by NASA (Reference: wikipedia ) How Flywheel Energy Storage Systems Work? Flywheel

Get Started

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss

Get Started

World''s largest flywheel energy storage

Sep 19, 2024 · A project in China, claimed as the largest flywheel energy storage system in the world, has been connected to the grid.

Get Started

Flywheel-lithium battery hybrid energy storage

Sep 2, 2020 · A hybrid energy storage system combining lithium-ion batteries with mechanical energy storage in the form of flywheels has gone into operation in

Get Started

Flywheel Energy Storage: The Key To Sustainable

Oct 16, 2024 · Flywheel energy storage is a promising technology that can provide fast response times to changes in power demand, with longer lifespan

Get Started

Overview of Flywheel Systems for Renewable Energy

Jul 12, 2024 · I. INTRODUCTION wind power. The intermittent nature of these resources may introduce issues with system stability, reliability and power quality. Storing power from these

Get Started

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Get Started

Flywheel energy storage systems: A critical

Jul 19, 2021 · Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

Get Started

Design and Experimental Study of a Toroidal Winding Flywheel Energy

Jan 3, 2025 · In this study, a toroidal winding flywheel energy storage motor is designed for low and medium speed occasions, aiming to meet the challenges of conventional high-speed

Get Started

FESS Fkywheel Energy Storage Systems

Jun 26, 2025 · In Australia do flywheels have a role as energy storage devices? All flywheel energy systems use the same basic concepts to store energy.

Get Started

Flywheel Storage Systems | SpringerLink

Dec 17, 2019 · The components of a flywheel energy storage systems are shown schematically in Fig. 5.4. The main component is a rotating mass that is held via magnetic bearings and

Get Started

Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · a rapidly spinning wheel - with 50 times the Storage capacity of a lead-acid battery As the flywheel is discharged and spun down, the stored rotational energy is transferred back

Get Started

Flywheel energy storage

Jan 1, 2022 · Flywheels are one of the earliest forms of energy storage and have found widespread applications particularly in smoothing uneven torque in engines and machinery.

Get Started

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Get Started

A Review of Flywheel Energy Storage System

Sep 7, 2023 · The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind

Get Started

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and

Get Started

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Get Started

Flywheel Energy Storage Basics

4 days ago · The high energy density and low maintenance requirements make it an attractive energy storage option for spacecraft. Conclusion: Flywheel

Get Started

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Get Started

A Review of Flywheel Energy Storage System Technologies

Sep 7, 2023 · Using energy storage technology can improve the stability and quality of the power grid. One such technology is flywheel energy storage systems (FESSs). Compared with other

Get Started

Flywheel Energy Storage System: What Is It and

In essence, a flywheel stores and releases energy just like a figure skater harnessing and controlling their spinning momentum, offering fast, efficient,

Get Started

6 FAQs about [Is Guinea a flywheel energy storage motor ]

How efficient is a flywheel energy storage system?

Their efficiency is high during energy storage and energy transfer (>90 %). The performance of flywheel energy storage systems operating in magnetic bearing and vacuum is high. Flywheel energy storage systems have a long working life if periodically maintained (>25 years).

Can flywheels be used for power storage systems?

Flywheels are now a possible technology for power storage systems for fixed or mobile installations. FESS have numerous advantages, such as high power density, high energy density, no capacity degradation, ease of measurement of state of charge, don’t require periodic maintenance and have short recharge times .

What type of motor is used in a flywheel energy storage system?

Permanent-Magnet Motors for Flywheel Energy Storage Systems The permanent-magnet synchronous motor (PMSM) and the permanent-magnet brushless direct current (BLDC) motor are the two primary types of PM motors used in FESSs. PM motors boast advantages such as high efficiency, power density, compactness, and suitability for high-speed operations.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Can small applications be used instead of large flywheel energy storage systems?

Small applications connected in parallel can be used instead of large flywheel energy storage systems. There are losses due to air friction and bearing in flywheel energy storage systems. These cause energy losses with self-discharge in the flywheel energy storage system.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

Related Articles

-

What are the lithium battery energy storage cabinet manufacturers in Guinea

What are the lithium battery energy storage cabinet manufacturers in Guinea

-

Can flywheel energy storage batteries be used

Can flywheel energy storage batteries be used

-

US 5G communication base station flywheel energy storage in 2025

US 5G communication base station flywheel energy storage in 2025

-

Apia communication base station flywheel energy storage brand has the most

Apia communication base station flywheel energy storage brand has the most

-

Flywheel energy storage AC or DC

Flywheel energy storage AC or DC

-

Flywheel energy storage and voltage regulation

Flywheel energy storage and voltage regulation

-

Loss of flywheel energy storage

Loss of flywheel energy storage

-

Support flywheel energy storage

Support flywheel energy storage

-

Communication base station flywheel energy storage cabinet protection box manufacturer

Communication base station flywheel energy storage cabinet protection box manufacturer

-

Flywheel energy storage 2 hours

Flywheel energy storage 2 hours

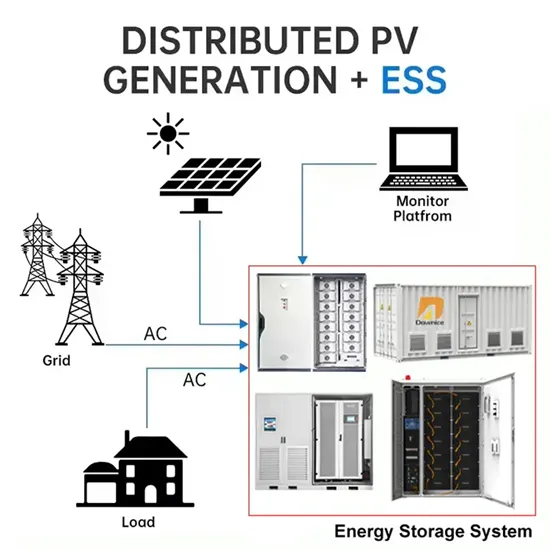

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

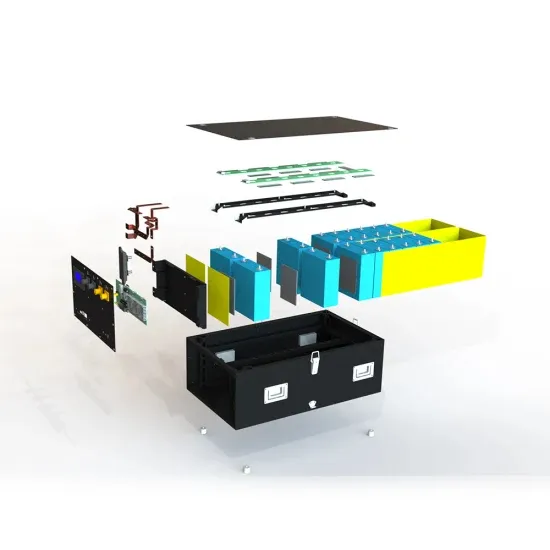

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.