Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · Monocrystalline silicon solar panels have an efficiency range of 18% to 22%, making them one of the most efficient photovoltaic panels available.

Get Started

Monocrystalline solar modules | SecondSol

Monocrystalline solar modules have an average efficiency of between 14 and 18%. Under particularly good conditions, the efficiency can even be 20%.

Get Started

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Get Started

High-efficiency Module,Longi solar module

3 days ago · LONGi High-efficiency solar Module, widely adopting PERC solar cells technology, Half-cut Module Technology and Bifacial PV

Get Started

Monocrystalline Silicon Photovoltaic Modules Market: Top

Jul 4, 2025 · Monocrystalline Silicon Photovoltaic Modules Market size was valued at USD 50.8 Billion in 2024 and is forecasted to grow at a CAGR of 7.

Get Started

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

Get Started

Optimization of monocrystalline silicon photovoltaic module

Jun 11, 2025 · This study presents a systematic approach to enhance the efficiency of monocrystalline silicon photovoltaic module assembly lines using advanced simulation

Get Started

Five-year performance and reliability analysis of monocrystalline

Sep 1, 2018 · This study analyses the performance and reliability of identical monocrystalline Silicon PV modules with different backsheet materials including aesthetically enhanced all

Get Started

Monocrystalline solar panels: the expert guide

Jul 25, 2025 · What are monocrystalline solar panels? Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which

Get Started

20_ET Hashim et al

Dec 27, 2018 · This paper indicates how the parameters of the five-parameter model are determined, also estimates the output power generated and other electrical and internal

Get Started

Low-carbon transition of China''s monocrystalline module

Aug 15, 2025 · Introduction Photovoltaics (PV) are widely regarded as a zero-carbon power generation solution and serve as a key driver in the low-carbon transition of China''s electricity

Get Started

Monocrystalline Silicon Photovoltaic Modules Market: Top

Jul 6, 2025 · Monocrystalline Silicon Photovoltaic Modules Market size was valued at USD 50.8 Billion in 2024 and is forecasted to grow at a CAGR of 7.

Get Started

Monocrystalline Silicon Photovoltaic Modules Market: A

Jul 6, 2025 · Monocrystalline Silicon Photovoltaic Modules Market size was valued at USD 50.8 Billion in 2024 and is forecasted to grow at a CAGR of 7.

Get Started

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Get Started

What is Monocrystalline Solar Panel: A

Mar 23, 2024 · A solar panel is technically known as PV or photovoltaic panel because each comprises small, interconnected PV cells. By the way, do you

Get Started

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Get Started

Study of the performance of five parameter model for monocrystalline

Jan 1, 2018 · Abstract and Figures This paper presents the construction of a model for a photovoltaic module using the single-diode five-parameter model, based exclusively on

Get Started

Top 10 Global Photovoltaic Module

Based on the 2025 market shipment forecast and technology analysis, this report provides an in-depth overview of the world''s top 10 photovoltaic module

Get Started

Top 10 Solar Silicon Wafer Manufacturers in China

Apr 27, 2023 · Photovoltaic silicon wafers are the upstream link of the photovoltaic industry chain, the upstream material of cells and modules, and

Get Started

High-efficiency Monocrystalline Silicon Solar Cells:

In this paper, the typical high-efficiency c-Si solar cells with conversion efficiencies of 25% or above are firstly summarized. The corresponding device structure, key technology and

Get Started

Full article: Performance comparison of monocrystalline and

Nov 23, 2024 · The advancements made in both first-generation photovoltaic (PV) cells and thin-film PV cells are incorporated in the second-generation PV cell technology, such as those

Get Started

Monocrystalline silicon solar energy specifications

What is a Monocrystalline Solar Module? Monocrystalline solar modules are panels assembled using ''''mono'''' cells - solar cells composed of single-crystal silicon. The single-crystal

Get Started

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost

Get Started

Optimization of monocrystalline silicon photovoltaic

Jun 11, 2025 · Monocrystalline silicon photovoltaic modules represent a pivotal component in the solar PV manufacturing value chain. Their production process involves assem-bling

Get Started

Performance comparison of mono and polycrystalline silicon

Feb 19, 2022 · The modules are located on the rooftop of an academic building ~15 metres above the ground. Two different SPV modules, made of monocrystalline silicon and polycrystalline

Get Started

High-efficiency Module,Longi solar module

9 hours ago · LONGi High-efficiency solar Module, widely adopting PERC solar cells technology, Half-cut Module Technology and Bifacial PV

Get Started

Crystalline Silicon Module

Monocrystalline silicon (mono c-Si): This type of c-Si module is widely used and will continue to be the leader of the PV market. At present, these modules seem to be readily available and the

Get Started

Monocrystalline Solar Panels: Advantages and

8 Good Reasons Why Monocrystalline Solar Panels are the Industry Standard Monocrystalline photovoltaic electric solar energy panels have been the go-to

Get Started

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Technologies based on crystalline silicon (c-Si) dominate the current PV market, and their MSPs are the lowest; the figure only shows the MSP for monocrystalline monofacial

Get Started

Performance Study of Monocrystalline and Polycrystalline Solar PV

Aug 11, 2020 · This paper evaluates the energy performance of two PV module technologies widely used in solar energy installations in Colombia, also commercially available in the

Get Started

Performance comparison of monocrystalline and

Nov 23, 2024 · How does the operat-ing temperature of photovoltaic modules affect the performance efficiency of monocrystalline and poly-crystalline modules in high latitudes before

Get Started

6 FAQs about [Top five monocrystalline silicon photovoltaic modules]

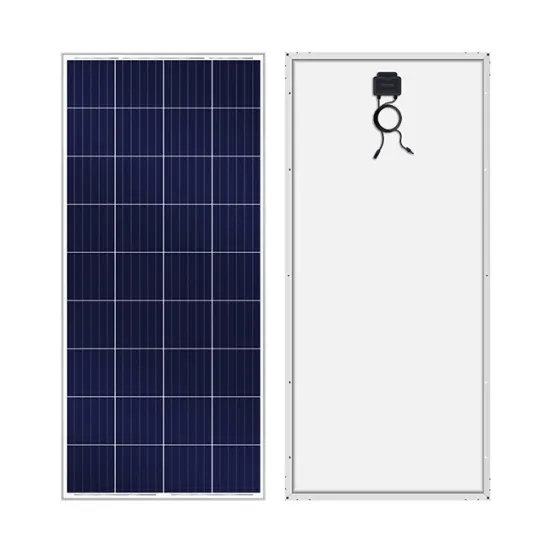

What are monocrystalline solar panels?

Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more smoothly, with less resistance. This ultimately means they have the highest efficiency ratings, longest lifespans, and best power ratings on the market, ahead of all other types of solar panels.

How much power does a monocrystalline solar panel have?

The best monocrystalline solar panels have power ratings upwards of 500W, with some exceeding 600W and even 700W. In contrast, you’ll struggle to find a polycrystalline panel with a power rating above 400W, and they’ve long fallen around 20% below monocrystalline models, according to data analysts Wood Mackenzie.

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

What are the different types of monocrystalline panels?

Amidst this stunning display of monocrystalline dominance, manufacturers paired these panels with five different technologies: TOPCon, PERC p-type and n-type, HJT, and back contact (more detail on these in the next section).

What is polycrystalline silicon?

Polycrystalline silicon, sometimes known as "polysilicon”, is a raw material used to produce monocrystalline or multi-crystalline silicon ingots. These ingots were then cut into wafers, processed into cells, and transformed into finished modules (Woodhouse et al., 2019).

Is crystalline silicon the future of solar technology?

Except for niche applications (which still constitute a lot of opportunities), the status of crystalline silicon shows that a solar technology needs to go over 22% module efficiency at a cost below US$0.2 W −1 within the next 5 years to be competitive on the mass market.

Related Articles

-

India Mumbai monocrystalline silicon photovoltaic modules

India Mumbai monocrystalline silicon photovoltaic modules

-

Top five monocrystalline silicon photovoltaic modules

Top five monocrystalline silicon photovoltaic modules

-

280W monocrystalline silicon photovoltaic panel

280W monocrystalline silicon photovoltaic panel

-

Romanian monocrystalline silicon photovoltaic panels wholesale

Romanian monocrystalline silicon photovoltaic panels wholesale

-

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

-

Photovoltaic module monocrystalline silicon efficiency

Photovoltaic module monocrystalline silicon efficiency

-

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

-

Cuban monocrystalline silicon photovoltaic panels

Cuban monocrystalline silicon photovoltaic panels

-

How to connect monocrystalline silicon photovoltaic panels in series

How to connect monocrystalline silicon photovoltaic panels in series

-

Price of crystalline silicon photovoltaic modules in Mumbai India

Price of crystalline silicon photovoltaic modules in Mumbai India

Commercial & Industrial Solar Storage Market Growth

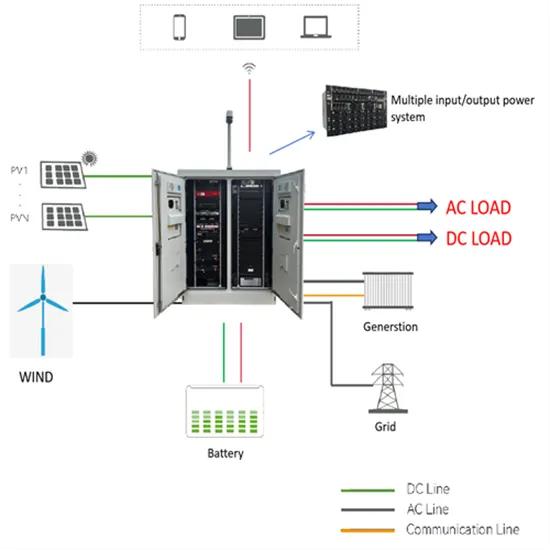

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.