Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Their distinguishing feature is their cells, which are made of monocrystalline silicon, a pure and homogeneous material that guarantees superior energy performance

Get Started

How to Distinguish Mono, Poly and Amorphous Silicon Solar Panels?

Oct 7, 2023 · Distinguishing between monocrystalline silicon, polycrystalline silicon, and amorphous silicon solar panels can be done by examining their physical appearance and

Get Started

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · What is the Meaning of Monocrystalline Silicon Solar Panels? When discussing solar panel meaning, monocrystalline silicon solar panels refer to

Get Started

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

Get Started

What is Monocrystalline Solar Panel: A Consolidated Guide

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Get Started

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Get Started

High-efficiency Monocrystalline Silicon Solar Cells:

In this paper, the typical high-efficiency c-Si solar cells with conversion efficiencies of 25% or above are firstly summarized. The corresponding device structure, key technology and

Get Started

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Get Started

Environmental impact assessment of monocrystalline silicon

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Get Started

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Learn everything you need to know about Crystalline Silicon PV technology, from its basic principles to its applications in solar panels.

Get Started

Cuban Government Bets on Solar Power: Jovellanos II Photovoltaic

Mar 24, 2025 · This week, the Cuban government received its first batch of equipment donated by China for the installation of photovoltaic solar parks, part of a joint project aimed at adding 120

Get Started

Monocrystalline solar panels – Uses, Benefits

Apr 17, 2024 · What Makes Monocrystalline Solar Panels Unique From Others? The manufacturing method and effectiveness of monocrystalline solar panels

Get Started

Monocrystalline Solar Panels: Advantages and

Good silicon feedstock is expensive (although less so in 2010 then it has been for a a while) and the cost of making a single pure crystal is time-comsuming and

Get Started

Monocrystalline silicon photovoltaic panel specifications

What are monocrystalline solar panels? Monocrystalline solar panels are made from single-crystal silicon,resulting in their distinctive dark black hue. This uniform structure,with fewer grain

Get Started

Monocrystalline Solar Panel — Everything You

Feb 27, 2021 · Because the silicon ingots have a rounded shape, a lot of material is lost when cutting it into the thinner required squared shape. That is why

Get Started

Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · Recycling of PV panel is currently not economically viable because waste volumes generated are too small; significant volumes of end-of-life photovoltaic panels will begin to

Get Started

Monocrystalline Solar Panels: A Comprehensive

A monocrystalline solar panel is a type of photovoltaic (PV) panel made from a single continuous crystal structure of silicon. This manufacturing process gives

Get Started

Solar panels and private sector: hope on rooftops

May 23, 2025 · From a technical standpoint, what type of solar collectors are you using? The systems we are installing are monocrystalline solar panels. We

Get Started

Monocrystalline vs. Polycrystalline solar panels

Jan 9, 2023 · The two main types of silicon solar panels are monocrystalline and polycrystalline. Learn their differences and compare mono vs poly solar.

Get Started

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

Get Started

Which is Better, Polycrystalline or

Aug 7, 2023 · The advantage of using monocrystalline photovoltaic panels is the greater efficiency, even in low light conditions, such as cloudier days.

Get Started

Monocrystalline Solar Panels: How They Work,

Sep 16, 2023 · Monocrystalline solar panels utilize monocrystalline silicon cells to transform sunlight into usable electrical energy. These cells are made from

Get Started

Comparison Between Monocrystalline Silicon Photovoltaic Panels

The photovoltaic conversion efficiency of monocrystalline silicon solar panels is generally higher than that of polycrystalline silicon panels, with top-tier monocrystalline panels achieving

Get Started

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Pupin, P.C., et al.: Monocrystalline silicon solar cell for producing monocrystalline photovoltaic panels: a case study of Brazil. Energy Sources Part a-Recovery Utilization and

Get Started

Monocrystalline silicon photovoltaic panel specifications

Monocrystalline solar panels are produced from one large silicon block in silicon wafer formats. The manufacturing process involves cutting individual wafers of silicon that can be

Get Started

Monocrystalline solar panels: the expert guide

Jul 25, 2025 · Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more

Get Started

The Pros and Cons of Monocrystalline Solar Panels

5 days ago · Monocrystalline solar panels are made from a single silicon crystal, which makes them the most efficient type of solar panels available. However,

Get Started

Cuban sun room photovoltaic panel manufacturer

Advanced Monocrystalline Solar Panels These advanced monocrystalline solar panels are crafted from single-crystal silicon, which endows them with outstanding electrical properties. They

Get Started

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Get Started

Types of PV Panels – Solar Photovoltaic

Compared to monocrystalline silicon, multicrystalline silicon PV cell is moderately efficient with a market efficiency ranging from 11-14%, as a result, the cost of

Get Started

Monocrystalline silicon: efficiency and

Sep 3, 2018 · Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels

Get Started

A Guide to Monocrystalline Solar Panels

Oct 7, 2024 · Monocrystalline solar cells are typically cut into shapes that are octagonal, square with rounded corners, or semi-round. Monocrystalline solar cells are also made from a very

Get Started

6 FAQs about [Cuban monocrystalline silicon photovoltaic panels]

Why is monocrystalline silicon used in solar panels?

Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels are not very demanding. In this type of boards the demands on structural imperfections are less high compared to microelectronics applications. For this reason, lower quality silicon is used.

What are monocrystalline solar panels?

Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more smoothly, with less resistance. This ultimately means they have the highest efficiency ratings, longest lifespans, and best power ratings on the market, ahead of all other types of solar panels.

Are monocrystalline photovoltaic panels a good choice?

Monocrystalline photovoltaic panels are at the forefront of solar technology due to their efficiency, durability and ability to generate energy even in confined spaces. They are considered an excellent choice for anyone wishing to install a high quality photovoltaic system, whether for residential or industrial use.

How many solar cells are in a single monocrystalline panel?

Based on their size, a single monocrystalline panel may contain 60-72 solar cells, among which the most commonly used residential panel is a 60-cells. Features A larger surface area due to their pyramid pattern. The top surface of monocrystalline panels is diffused with phosphorus, which creates an electrically negative orientation.

How are monocrystalline photovoltaic cells made?

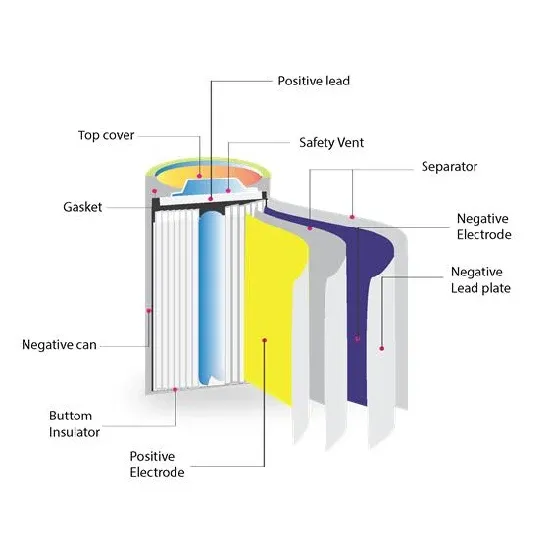

Monocrystalline photovoltaic cells are made from a single crystal of silicon using the Czochralski process. In this process, silicon is melted in a furnace at a very high temperature.

What is monocrystalline silicon used for?

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation.

Related Articles

-

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

-

Romanian monocrystalline silicon photovoltaic panels wholesale

Romanian monocrystalline silicon photovoltaic panels wholesale

-

Monocrystalline silicon distributed photovoltaic panels

Monocrystalline silicon distributed photovoltaic panels

-

How to connect monocrystalline silicon photovoltaic panels in series

How to connect monocrystalline silicon photovoltaic panels in series

-

Laayoune monocrystalline silicon photovoltaic panels

Laayoune monocrystalline silicon photovoltaic panels

-

Photovoltaic module monocrystalline silicon efficiency

Photovoltaic module monocrystalline silicon efficiency

-

Bangkok is suitable for installing photovoltaic monocrystalline panels

Bangkok is suitable for installing photovoltaic monocrystalline panels

-

Power station monocrystalline silicon photovoltaic modules

Power station monocrystalline silicon photovoltaic modules

-

Guatemala monocrystalline photovoltaic panels

Guatemala monocrystalline photovoltaic panels

-

Resistivity of photovoltaic cell silicon panels

Resistivity of photovoltaic cell silicon panels

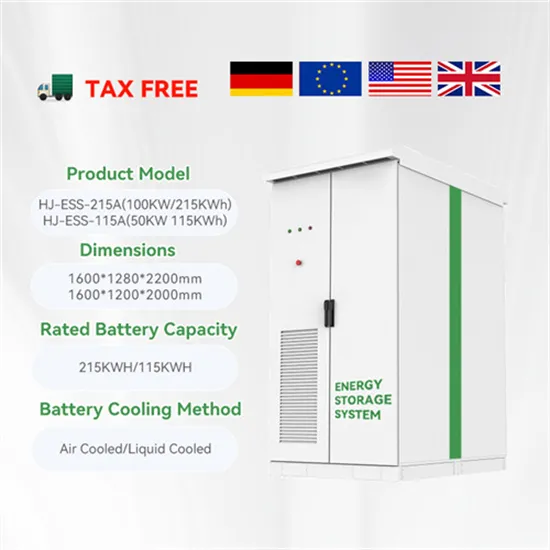

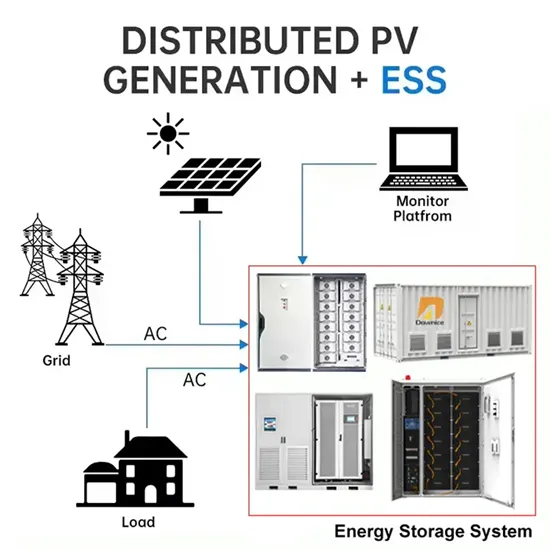

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.