Environmental impact assessment of monocrystalline silicon

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Get Started

A Guide to Monocrystalline Solar Panels

Oct 7, 2024 · Monocrystalline solar cells are typically cut into shapes that are octagonal, square with rounded corners, or semi-round. Monocrystalline solar cells are also made from a very

Get Started

Types of Solar Panels: Monocrystalline vs

Jan 30, 2024 · Introduction: Solar panels are a popular choice for renewable energy generation. It is important to understand the different types of solar

Get Started

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Pupin, P.C., et al.: Monocrystalline silicon solar cell for producing monocrystalline photovoltaic panels: a case study of Brazil. Energy Sources Part a-Recovery Utilization and

Get Started

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Learn everything you need to know about Crystalline Silicon PV technology, from its basic principles to its applications in solar panels.

Get Started

(PDF) Performance of different silicon PV technologies

The results presented in this paper concerned a comparative and performance analysis of three PV technologies Monocrystalline (2kWp), Polycrystalline (1.82kWp) and Amorphous

Get Started

What is Monocrystalline Solar Panel: A

Mar 23, 2024 · A solar panel is technically known as PV or photovoltaic panel because each comprises small, interconnected PV cells. By the way, do you

Get Started

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

Get Started

Which is Better, Polycrystalline or

Aug 7, 2023 · The advantage of using monocrystalline photovoltaic panels is the greater efficiency, even in low light conditions, such as cloudier days.

Get Started

The Pros and Cons of Monocrystalline Solar Panels

5 days ago · Monocrystalline solar panels are made from a single silicon crystal, which makes them the most efficient type of solar panels available. However,

Get Started

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous silicon, deposited onto a

Get Started

Energy efficiency of polycrystalline cells installed in

Feb 7, 2023 · A study of the performance of the in-stallation at the Laayoune Higher School of Technology (ESTL) was made by determining the performance, productivity, performance

Get Started

Crystalline Silicon Photovoltaics

Crystalline Silicon Photovoltaics Characteristics of crystalline silicon photovoltaics Crystalline silicon photovoltaics is the most widely used photovoltaic

Get Started

Defect analysis and performance evaluation of photovoltaic

Jan 8, 2025 · Experimental results indicate that monocrystalline silicon panels have the lowest degradation rate, ranging from 0.861% to 0.886%, compared to thin-film panels, which range

Get Started

Monocrystalline Solar Panel — Everything You

Feb 27, 2021 · Because the silicon ingots have a rounded shape, a lot of material is lost when cutting it into the thinner required squared shape. That is why

Get Started

Monocrystalline Solar Panels: Advantages and

Good silicon feedstock is expensive (although less so in 2010 then it has been for a a while) and the cost of making a single pure crystal is time-comsuming and

Get Started

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · What is the Meaning of Monocrystalline Silicon Solar Panels? When discussing solar panel meaning, monocrystalline silicon solar panels refer to

Get Started

Monocrystalline vs Polycrystalline Solar Panels

Feb 20, 2021 · Creating Silicon Ingots What differs monocrystalline cells from polycrystalline cells is that monocrystalline panels are made of a single pure

Get Started

Experimental comparison between Monocrystalline,

May 11, 2022 · This study presents the performance indicators for about six years of operation for a solar field that consists of five different solar systems (around 5 kW each), these systems are

Get Started

Monocrystalline silicon: efficiency and

Sep 3, 2018 · Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels

Get Started

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Get Started

(PDF) Performance of different silicon PV

Jun 1, 2020 · The results presented in this paper concerned a comparative and performance analysis of three PV technologies Monocrystalline (2kWp),

Get Started

Mono-crystalline silicon photovoltaic cells under different

Dec 1, 2020 · First, mathematical modeling of the Mono-crystalline PV module in case of various irradiation levels is presented. A performance assessment of a PV module by considering the

Get Started

Monocrystalline vs. Polycrystalline solar panels

Jan 9, 2023 · The two main types of silicon solar panels are monocrystalline and polycrystalline. Learn their differences and compare mono vs poly solar.

Get Started

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Known for their sleek black appearance, these panels excel in energy conversion and perform exceptionally well in low-light and high

Get Started

Monocrystalline solar panels – Uses, Benefits

Apr 17, 2024 · What Makes Monocrystalline Solar Panels Unique From Others? The manufacturing method and effectiveness of monocrystalline solar panels

Get Started

Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · Recycling of PV panel is currently not economically viable because waste volumes generated are too small; significant volumes of end-of-life photovoltaic panels will begin to

Get Started

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

Get Started

6 FAQs about [Laayoune monocrystalline silicon photovoltaic panels]

Is monocrystalline PV better than polycrystalline PV?

Monocrystalline PV system’s configurations outperformed other technologies in terms of efficiency (12.8%), performance ratio (80.5%) and specific yield per unit area (267 kWh/m 2). Accordingly, it is well-placed for sunny climates with moderate temperatures. Polycrystalline systems showed a lower performance in comparison to Monocrystalline.

What is the difference between polycrystalline and monocrystalline solar panels?

At present, the polycrystalline and monocrystalline modules are mainly used in the rooftop or ground photovoltaic systems, the monocrystalline module has the good power generation yield and save the cost of land or rooftop with the same installed capacity.

Do monocrystalline solar panels deteriorate after 5 years of Operation?

Table 9. Degradation of monocrystalline PV panels after 5 years of operation. The EL images of the monocrystalline solar panel, as shown in Fig. 5, reveal performance degradation caused by defects such as micro-cracks and folds, which create shaded areas and reduce the panel’s ability to convert solar energy into electricity.

What is the degradation rate of monocrystalline PV panels?

Table 9 presents the calculated degradation rates of the monocrystalline PV panels over the 5-year period. The results indicate that the annual degradation rate ranges from 0.282% to 0.354%, with an overall average degradation rate of 0.861% to 0.886% per year. Table 8. The EL results of two monocrystalline PV panels after 5 years of operation.

Why is monocrystalline silicon used in solar panels?

Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels are not very demanding. In this type of boards the demands on structural imperfections are less high compared to microelectronics applications. For this reason, lower quality silicon is used.

How do environmental and structural factors affect the performance of polycrystalline PV panels?

Figure 4. Analysis results using EL imaging of polycrystalline PV panels. These environmental and structural factors collectively diminish the overall efficiency of the system. Performance indicators such as FF, Voc, and degradation rate are directly impacted by these defects.

Related Articles

-

New monocrystalline silicon photovoltaic panels

New monocrystalline silicon photovoltaic panels

-

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

-

Cuban monocrystalline silicon photovoltaic panels

Cuban monocrystalline silicon photovoltaic panels

-

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

-

Romanian monocrystalline silicon photovoltaic panels wholesale

Romanian monocrystalline silicon photovoltaic panels wholesale

-

Bangkok Monocrystalline Photovoltaic Panels

Bangkok Monocrystalline Photovoltaic Panels

-

Monocrystalline silicon solar panels can provide 220v water pumps

Monocrystalline silicon solar panels can provide 220v water pumps

-

Apia monocrystalline photovoltaic module panels

Apia monocrystalline photovoltaic module panels

-

Ouagadougou monocrystalline photovoltaic panels

Ouagadougou monocrystalline photovoltaic panels

-

Guatemala monocrystalline photovoltaic panels

Guatemala monocrystalline photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

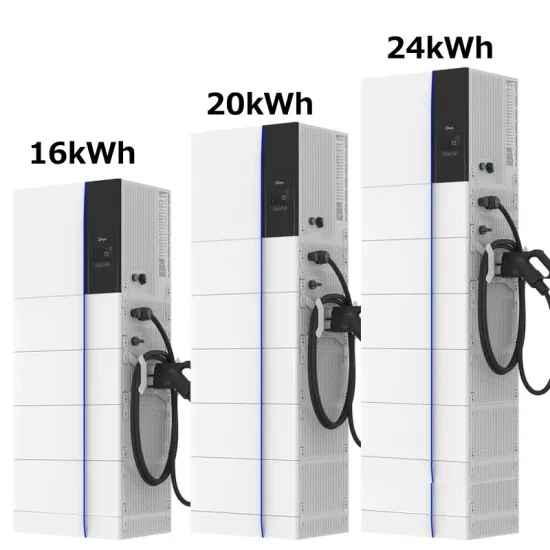

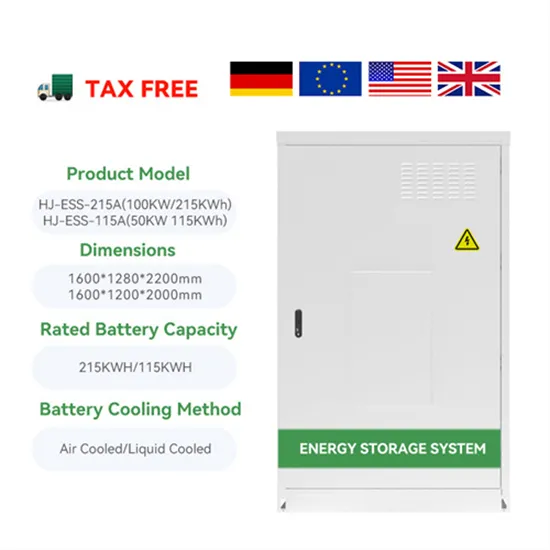

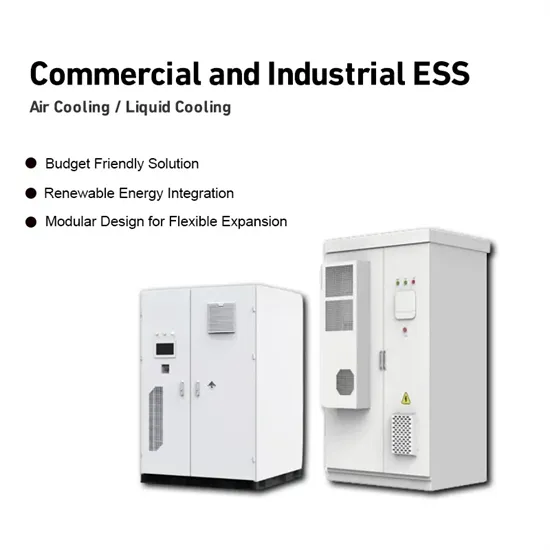

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.