China revises PV industry standards

Nov 26, 2024 · The MIIT has also raised the efficiency standards for new monocrystalline silicon PV cells and modules, which were 23 percent and 20 percent in the 2021 regulations,

Get Started

Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · Recycling of PV panel is currently not economically viable because waste volumes generated are too small; significant volumes of end-of-life photovoltaic panels will begin to

Get Started

Experimental comparison between Monocrystalline,

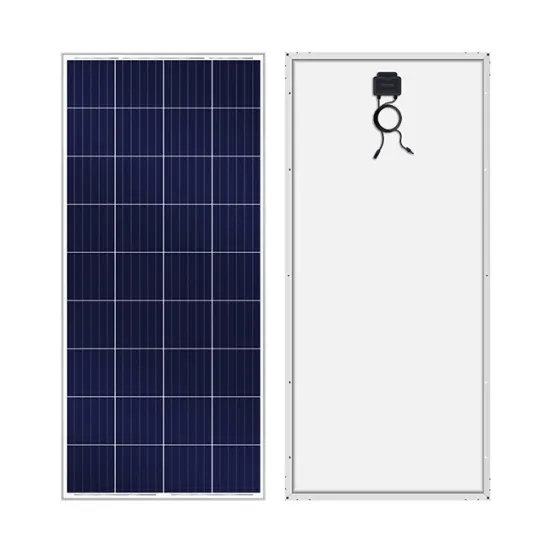

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

Get Started

Types of photovoltaic solar panels and their

Nov 6, 2017 · Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal.

Get Started

Most efficient solar panels 2025

Jul 24, 2025 · What makes the most efficient solar panels? At present, silicon-based monocrystalline panels are the most efficient type available. However,

Get Started

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Get Started

The 6 types of solar panels | What''s the best

Jun 12, 2025 · What are the main types of solar panels? The six main types of solar panels are polycrystalline, monocrystalline, thin-film, transparent, solar

Get Started

How Monocrystalline Solar Cells Work

May 10, 2012 · If you see a solar panel, the chances are it''s made of monocrystalline solar cells. They are by far the most widely used solar

Get Started

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

Get Started

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost

Get Started

Monocrystalline Solar Panels: How They Work,

Sep 16, 2023 · Monocrystalline solar panels utilize monocrystalline silicon cells to transform sunlight into usable electrical energy. These cells are made from

Get Started

What are monocrystalline, polycrystalline and

Aug 25, 2014 · There are a number of different technologies used to create solar panels. PV cells have been produced since the 1950s and for a long time,

Get Started

Monocrystalline vs Polycrystalline Solar Panels

Feb 20, 2021 · Creating Silicon Ingots What differs monocrystalline cells from polycrystalline cells is that monocrystalline panels are made of a single pure

Get Started

Monocrystalline Silicon PV Panels: Current Status and Future

In the current global energy transition, monocrystalline silicon PV panels have become a standout product in the renewable energy sector due to their high efficiency, stability, and reliability. This

Get Started

Enhancement of efficiency in monocrystalline silicon

Sep 6, 2024 · As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including monocrystalline and polycrystalline

Get Started

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · With advanced technology such as monocrystalline silicon photovoltaic modules with Backcontact Conductive Backsheet, Trienergia offers panels designed for maximum

Get Started

Monocrystalline solar panels: the expert guide

Jul 25, 2025 · Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more

Get Started

Comprehensive investigation of rooftop photovoltaic power

May 3, 2025 · In this study, a comprehensive 3E analysis of an existing rooftop PV power plant combining monocrystalline and polycrystalline silicone PV cell technologies has been carried out.

Get Started

The 9 Types of Solar Panels in the UK | 2025

Jun 3, 2025 · Currently available to homeowners Monocrystalline panels are made of single-crystal silicon, which is melted into bars, cut into wafers, and

Get Started

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · Monocrystalline silicon solar panels have an efficiency range of 18% to 22%, making them one of the most efficient photovoltaic panels available.

Get Started

Prospects for reusing silicon from end-of-life

Dec 27, 2024 · Scientists in the Netherlands proposed a new testing scheme for recycling silicon from end-of-life photovoltaic panels. Their methodology

Get Started

Monocrystalline Silicon PV: 5 Advantages Over Alternatives

Jun 30, 2025 · Monocrystalline silicon PV offers 22-26% efficiency (vs 15-18% for polycrystalline), 25-year lifespan with <0.5% annual degradation. Its low-light performance generates 10%

Get Started

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Get Started

Monocrystalline solar panels – Uses, Benefits

Apr 17, 2024 · What Makes Monocrystalline Solar Panels Unique From Others? The manufacturing method and effectiveness of monocrystalline solar panels

Get Started

Monocrystalline Solar Panel — Everything You

Feb 27, 2021 · Because the silicon ingots have a rounded shape, a lot of material is lost when cutting it into the thinner required squared shape. That is why

Get Started

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · As global efforts intensify in response to climate change, establishing a new energy system predominantly based on renewable sources has become a critical necessity to

Get Started

What is Monocrystalline Solar Panel?

Jan 19, 2021 · What is a monocrystalline solar panel? A monocrystalline solar panel is a solar panel comprising monocrystalline solar cells. The panel

Get Started

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Get Started

Understanding Monocrystalline Solar Panels

Apr 10, 2024 · Monocrystalline solar panels are made from a single crystal of silicon, which is a semiconductor material that can convert sunlight into

Get Started

Enhancement of efficiency in monocrystalline

Dec 20, 2023 · As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including

Get Started

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous silicon, deposited onto a

Get Started

A Guide to Monocrystalline Solar Panels

Oct 7, 2024 · Monocrystalline solar cells are typically cut into shapes that are octagonal, square with rounded corners, or semi-round. Monocrystalline solar cells are also made from a very

Get Started

6 FAQs about [New monocrystalline silicon photovoltaic panels]

What are monocrystalline solar panels?

Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more smoothly, with less resistance. This ultimately means they have the highest efficiency ratings, longest lifespans, and best power ratings on the market, ahead of all other types of solar panels.

Are monocrystalline photovoltaic panels a good choice?

Monocrystalline photovoltaic panels are at the forefront of solar technology due to their efficiency, durability and ability to generate energy even in confined spaces. They are considered an excellent choice for anyone wishing to install a high quality photovoltaic system, whether for residential or industrial use.

How are monocrystalline photovoltaic cells made?

Monocrystalline photovoltaic cells are made from a single crystal of silicon using the Czochralski process. In this process, silicon is melted in a furnace at a very high temperature.

How much power does a monocrystalline solar panel have?

The best monocrystalline solar panels have power ratings upwards of 500W, with some exceeding 600W and even 700W. In contrast, you’ll struggle to find a polycrystalline panel with a power rating above 400W, and they’ve long fallen around 20% below monocrystalline models, according to data analysts Wood Mackenzie.

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

Why should you choose a monocrystalline solar module?

With no visible solder joints and optimal energy management, these monocrystalline modules guarantee high performance and long life, making them ideal for residential and industrial applications. If you want to invest in high quality solar energy, choose the most advanced monocrystalline technology.

Related Articles

-

Romanian monocrystalline silicon photovoltaic panels wholesale

Romanian monocrystalline silicon photovoltaic panels wholesale

-

Laayoune monocrystalline silicon photovoltaic panels

Laayoune monocrystalline silicon photovoltaic panels

-

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

-

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

-

Brand new monocrystalline photovoltaic panels for sale in Ireland

Brand new monocrystalline photovoltaic panels for sale in Ireland

-

Cuban monocrystalline silicon photovoltaic panels

Cuban monocrystalline silicon photovoltaic panels

-

New photovoltaic panels for sale in Kazakhstan

New photovoltaic panels for sale in Kazakhstan

-

3 2v monocrystalline silicon solar photovoltaic panel

3 2v monocrystalline silicon solar photovoltaic panel

-

Photovoltaic module monocrystalline silicon efficiency

Photovoltaic module monocrystalline silicon efficiency

-

Power station monocrystalline silicon photovoltaic modules

Power station monocrystalline silicon photovoltaic modules

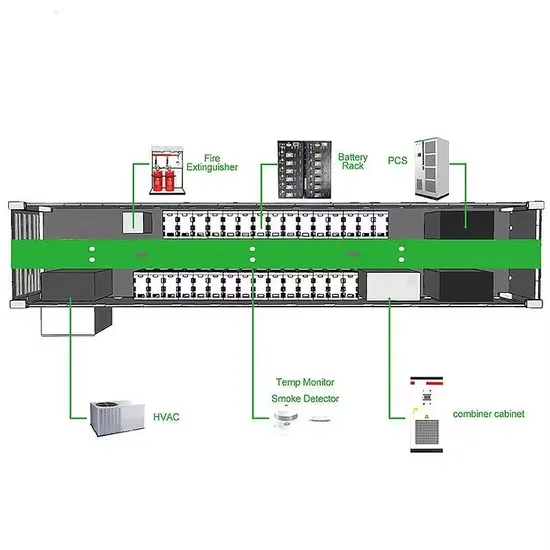

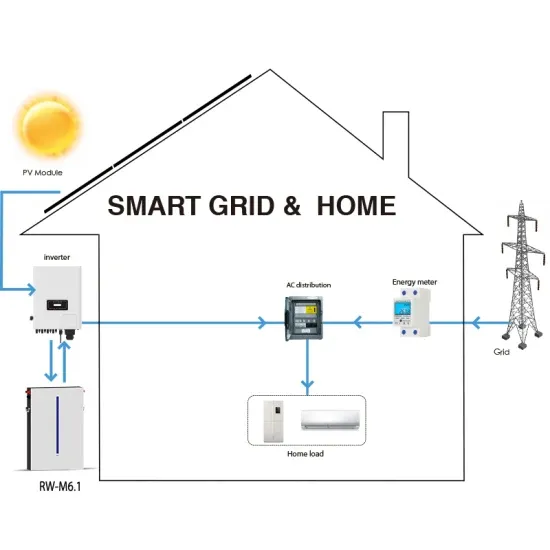

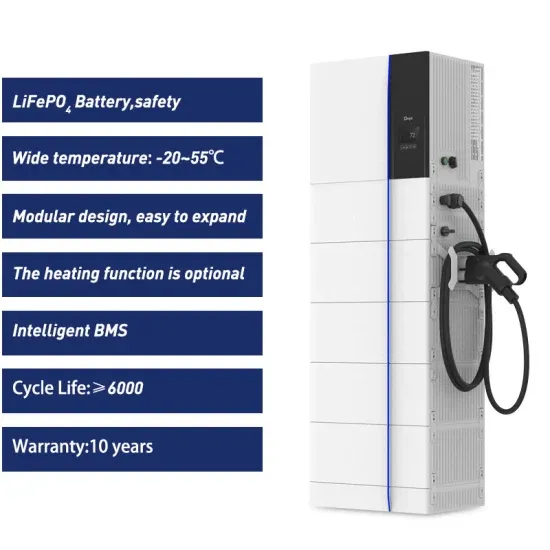

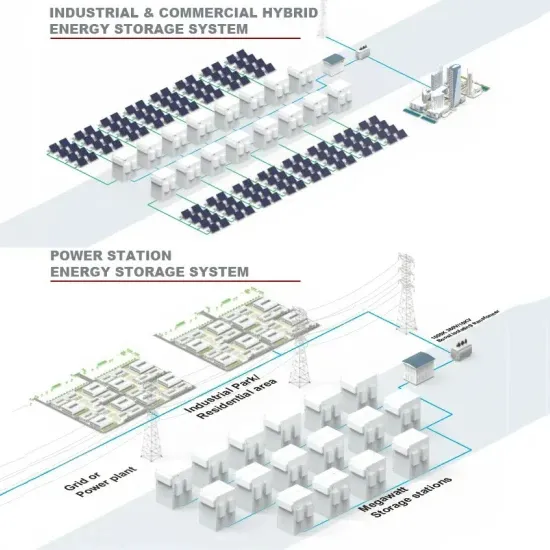

Commercial & Industrial Solar Storage Market Growth

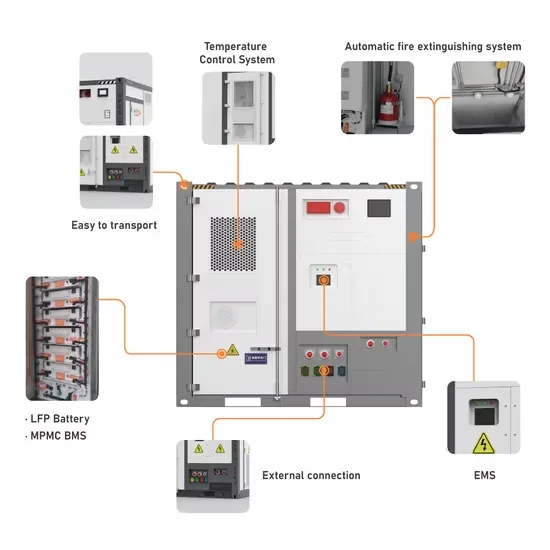

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.