Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost

Get Started

High Resistivity Silicon Wafers Market in Japan

4 days ago · Solar power is also being emphasized, where high resistivity silicon wafers are used in the manufacturing of photovoltaic cells for solar panels. With Japan reducing carbon dioxide

Get Started

Introduction to photovoltaics and alternative materials for silicon

Jan 1, 2021 · The first generation belongs to the bulk crystalline silicon-based solar cell (monocrystalline and multicrystalline), which exhibited the most mature technology with

Get Started

Measurement of Contact Resistivity In Symmetric

Mar 27, 2025 · We propose a universal method to extract contact resistivity on symmetric test structures with polycrystalline silicon on SiO x (poly-Si/SiO x) passivating contacts under

Get Started

Conductive Copper Paste for Crystalline Silicon

Nov 5, 2018 · In photovoltaic industries, the main technique of metallization is screen printing with silver pastes due to its simple and quick process.

Get Started

A global statistical assessment of designing

Jun 19, 2024 · This work optimizes the design of single- and double-junction crystalline silicon-based solar cells for more than 15,000 terrestrial locations.

Get Started

Structural and efficiency analysis of polycrystalline Si cells

Jun 23, 2025 · In comparison with other specimens, the blended VO 2 -Si 3 N 4 specimen exhibited minimum resistivity (5.36 × 10 −3 Ω cm). The impact of cell temperature on ARC

Get Started

Effect of rapid thermal annealing on photovoltaic properties of silicon

Dec 15, 2023 · In recent years, the growing demand for renewable energy sources has led to an increased interest for searching some ways to improve the factors affecting the power

Get Started

Encapsulation of commercial and emerging solar cells with

May 1, 2022 · Photovoltaics (PV) is a rapidly growing energy production method, that amounted to around 2.2% of global electricity production in 2019 (Photovoltaics Report - Fraunhofer ISE,

Get Started

Influence of the Bulk Resistivity on Silicon

Dec 21, 2021 · We measure the current–voltage characteristics of n-type cells across the resistivity range, and we find comparable responses to illumination

Get Started

Electrical Loss Reduction in Crystalline Silicon

ABSTRACT: The output power of a crystalline silicon (c-Si) photovoltaic (PV) module is not directly the sum of the powers of its unit cells. There are several losses and gain mechanisms

Get Started

Temperature and illumination dependence of silicon

Dec 22, 2022 · Recently, the significant improvements in the surface and contact passivation of silicon (Si) solar cells as well as their bulk quality have shifted their operating point to higher

Get Started

Crystalline Silicon Module

Crystalline silicon cell fabrication: Crystalline silicon PV cells are fabricated from the so-called "semiconductor silicon" that is prepared from metallurgical silicon by decomposition of SiHCl 3

Get Started

Solar Energy and Silver

Jun 15, 2022 · A silver paste is a critical element in both photovoltaic cells and crystalline silicon photovoltaic cells. Due to the crucial importance of

Get Started

Contact Resistivity and Sheet Resistance Measurements of Cells

Jun 21, 2019 · The electrical performance of a photovoltaic (PV) module is greatly hindered by the existence of parasitic resistance losses, such as high series resistance (Rs

Get Started

Individual efficiencies of a polycrystalline silicon PV cell versus

Aug 1, 2021 · The base doping level on which the open circuit voltage depends can be used to improve the temperature resistivity of the polycrystalline silicon PV cell. A comparison was

Get Started

Resistivity of crystalline silicon photovoltaic cell to the

Jun 1, 2025 · Crystalline silicon PV cells can resist well to the EMF effects at 1 0 17 cm − 3. The thermalization mechanism is unaffected by the EMF and doping rate. Doping level of 1 0 16 to

Get Started

Semiconductor Materials for Solar PV

Aug 21, 2022 · Gallium nitride and silicon carbide power semiconductors will emerge to bring the efficiency high in the photovoltaic technology.

Get Started

Temperature profiles of field-aged photovoltaic modules

Sep 1, 2023 · PV modules affected by optical degradation show weak fluorescence and luminescence signal intensities. The average difference in cell temperature (ΔT) between the

Get Started

Advanced polymer encapsulates for photovoltaic devices −

Sep 1, 2021 · The efficiency of a PV module mainly depends on the PV cell technology and the lifetime of a PV cell under operation is a significant concern for the widespread

Get Started

Influence of the Bulk Resistivity on Silicon Heterojunction

Dec 21, 2021 · Herein, n- and p-type silicon heterojunction cells with bulk resistivities between 3 and 15 000 Ωcm are studied. We measure the current–voltage characteristics of n-type cells

Get Started

Deciphering the Role of Hydrogen in the Degradation of Silicon

Sep 6, 2024 · 1 Introduction Hydrogen is found to enhance the performance of silicon (Si) solar cells by passivating defects in the bulk and at the surface. [1] Regarding bulk defects,

Get Started

Performance of silicon heterojunction solar cells using high

Jun 21, 2019 · Abstract: We investigate the potential advantages of using very high resistivity n- and p-type, to manufacture high performance solar cells. Analytical modeling indicates that

Get Started

Types of Encapsulant Materials and Physical Differences

Mar 4, 2010 · Si CH3 CH3 m CH3 n Dow Corning Corporation, "Develop silicone Encapsulation Systems for Terrestrial Silicon Solar Arrays", Doe/JPL954995-2 (1978). M. A. Green, "Silicon

Get Started

Purification of silicon for photovoltaic applications

Dec 1, 2012 · Solar grade silicon, as a starting material for crystallization to produce solar cells, is discussed here in terms of impurities whose maximum content is estimated from recent

Get Started

Progress in n-type monocrystalline silicon for high

May 21, 2024 · ABsTrACT Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are

Get Started

Module Encapsulation Materials, Processing and Testing

Sep 20, 2013 · Functions: Optical coupling – refractive index (n) matching Electrical Insulation – dielectric strength and volume resistivity Mechanical support – fixation of cells and adhesion

Get Started

Silicon heterojunction solar cells: Techno

Crystalline silicon heterojunction photovoltaic technology was conceived in the early 1990s. Despite establishing the world record power conversion efficiency

Get Started

Temperature-dependent performance of silicon solar cells

Jun 15, 2021 · In this study, we investigate the temperature dependence of the performance of TOPCon solar cells and quantify their TCs. To gain better understanding regarding the

Get Started

Silicon solar cells: materials, technologies, architectures

Jan 1, 2020 · This chapter reviews the field of silicon solar cells from a device engineering perspective, encompassing both the crystalline and the thin-film silicon technologies. After a

Get Started

6 FAQs about [Resistivity of photovoltaic cell silicon panels]

Does resistivity affect P-Topcon solar cells?

sistivity of silicon wafers has a crucial impact on their performance. This study inves igated the effects of different resistivities on p-TOPCon solar cells. The results indicate that lower resistivity wafers have a higher implied open-circuit voltage (iVoc) value, but higher carrier mobility due to the l

What changes have been made to silicon PV components?

In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost and the general implementation of diamond wire sawing has reduced the cost of monocrystalline wafers.

What is the conversion efficiency of crystalline silicon heterojunction solar cells?

Masuko, K. et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J. Photovolt. 4, 1433–1435 (2014). Boccard, M. & Holman, Z. C. Amorphous silicon carbide passivating layers for crystalline-silicon-based heterojunction solar cells. J. Appl. Phys. 118, 065704 (2015).

How efficient are p-type crystalline silicon solar cells with hole-selective passivating contacts?

Yan, D., Cuevas, A., Phang, S. P., Wan, Y. & Macdonald, D. 23% efficient p-type crystalline silicon solar cells with hole-selective passivating contacts based on physical vapor deposition of doped silicon films. Appl. Phys. Lett. 113, 61603 (2018).

How does resistivity affect recombination of solar cells?

w resistivity leads to an increase in saturation current density (J0). Conversely, solar cells made on higher resistivity silicon wafers have a lower carrier mobility, leading to slower electron-hole recombination and lower bulk recombination, resulting in the advantage of

What is crystalline silicon (c-Si) photovoltaics?

Provided by the Springer Nature SharedIt content-sharing initiative Crystalline silicon (c-Si) photovoltaics has long been considered energy intensive and costly. Over the past decades, spectacular improvements along the manufacturing chain have made c-Si a low-cost source of electricity that can no longer be ignored.

Related Articles

-

Romanian monocrystalline silicon photovoltaic panels wholesale

Romanian monocrystalline silicon photovoltaic panels wholesale

-

Nicosia Photovoltaic Cell Panels

Nicosia Photovoltaic Cell Panels

-

Monocrystalline silicon distributed photovoltaic panels

Monocrystalline silicon distributed photovoltaic panels

-

Togo photovoltaic silicon panels

Togo photovoltaic silicon panels

-

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

Photovoltaic conversion rate of monocrystalline silicon photovoltaic panels

-

How to connect monocrystalline silicon photovoltaic panels in series

How to connect monocrystalline silicon photovoltaic panels in series

-

Cuban monocrystalline silicon photovoltaic panels

Cuban monocrystalline silicon photovoltaic panels

-

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

Majuro Monocrystalline Silicon Solar Photovoltaic Panels

-

Are a few photovoltaic panels enough for home use

Are a few photovoltaic panels enough for home use

-

Price difference between single-glass and double-glass photovoltaic panels

Price difference between single-glass and double-glass photovoltaic panels

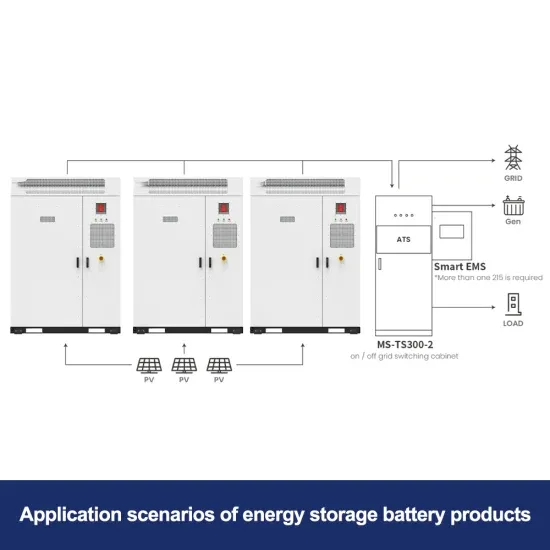

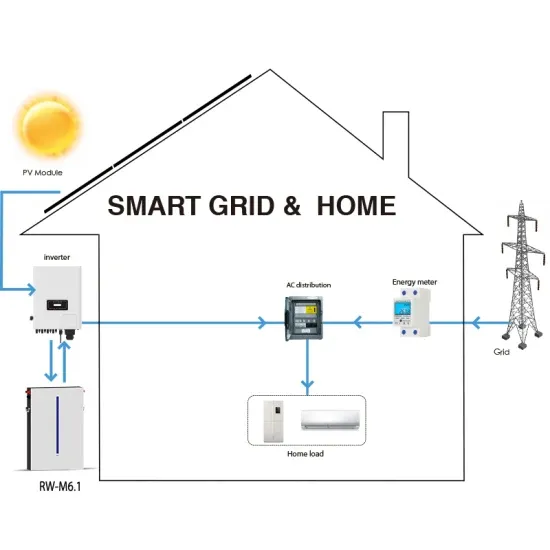

Commercial & Industrial Solar Storage Market Growth

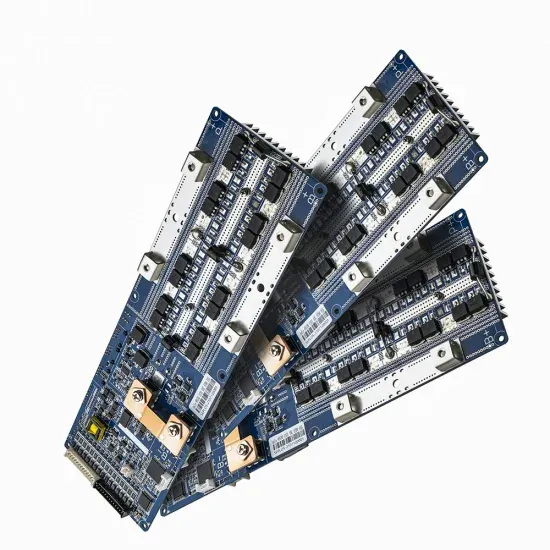

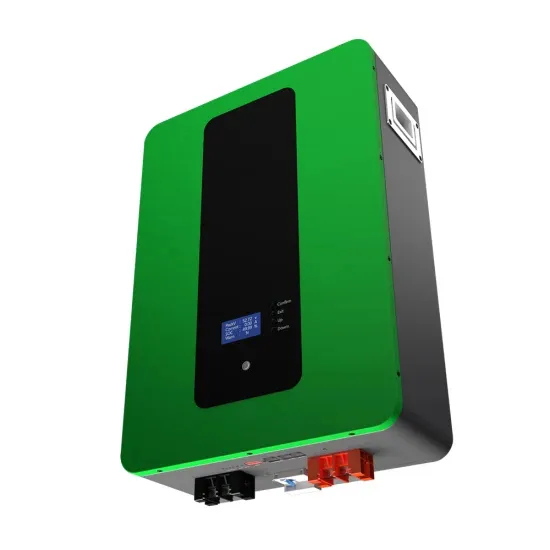

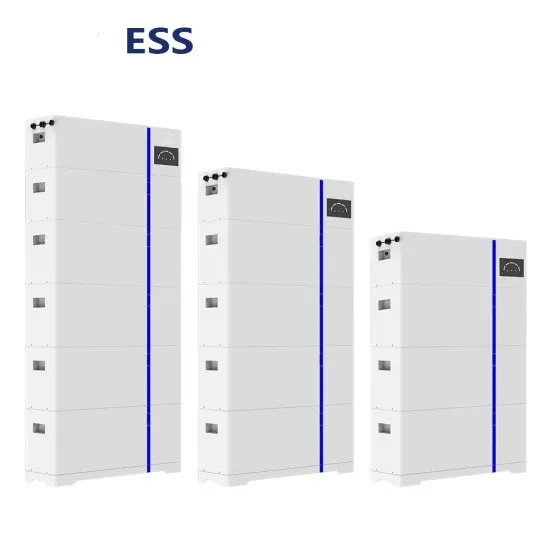

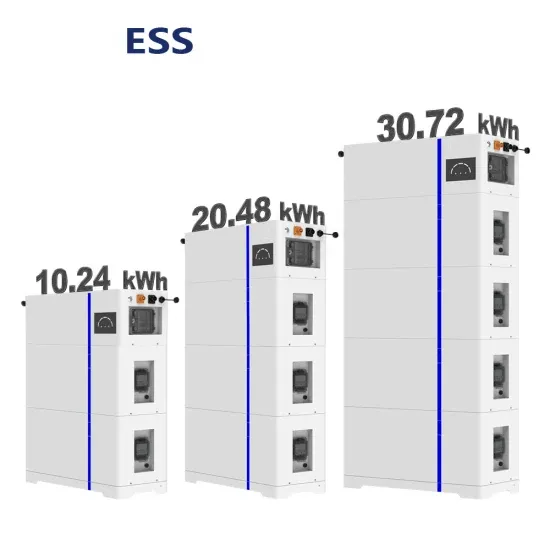

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.