Inner Mongolia: 1GW/6GWh! World''s Largest

Jul 7, 2025 · The project adopts advanced lithium iron phosphate energy storage technology, integrating power conversion and boosting systems with an

Get Started

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

Get Started

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

Get Started

What are the lithium battery energy storage

Mar 10, 2024 · Inner Mongolia holds a pivotal position regarding lithium battery energy storage initiatives due to several essential factors that underline its

Get Started

Lithium-ion Battery Production | Bühler Group

Bühler''s lithium-ion battery (LIB) manufacturing solutions cover crucial process steps. They include wet grinding active materials and precursors plus a

Get Started

(PDF) Lithium-ion Battery Cell Production

Feb 6, 2019 · Abstract The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium

Get Started

Current and future lithium-ion battery

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode

Get Started

Direct recycling of Li-ion batteries from cell to

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

Get Started

20GWh lithium battery project settled in Hohhot,

Apr 26, 2023 · The construction content of this contracted project includes an annual output of 20GWh lithium battery production workshop, pack workshop,

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

How to Revive a Lithium-Ion Battery: Step-by

Nov 21, 2024 · Safety Measures Before Attempting Battery Revival Before attempting to revive a lithium-ion battery, you need to take safety measures.

Get Started

Mechanical Design and Packaging of Battery

Feb 11, 2018 · In this work, the integration of Lithium-ion battery into an EV battery pack is investigated from different aspects, namely different battery

Get Started

(PDF) Lithium Deposits of Mongolia

The most important means of storing energy is the lithium battery and the capacitor, therefore the significance is high for conducting studies on the most important raw material of lithium battery

Get Started

How Mongolia can play a role in global battery

Jul 11, 2021 · According to CEO Ali Haji, the capabilities of lithium-ion batteries and the ever-increasing demand for electric vehicles around the world have

Get Started

(Infographics #3) Battery Making at a Glance

Jun 14, 2023 · (Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode

Get Started

Promote carbon neutralization, Mongolia Lithium battery

The leadership team of Mongolia Lithium battery crushing and recycling equipment Chinese manufacturer Mongolia crushing equipment Lithium battery circuit board recycling supplier-

Get Started

Custom Lithium Battery Pack Manufacturing: A

Mar 1, 2025 · At Vade Battery, we''ve refined a 14-stage development protocol that combines aerospace-grade engineering rigor with commercial manufacturing

Get Started

Lithium Battery Packs Customized For Electric Vehicles

Questions That Are Frequently Asked in Relation to the Customized Lithium Battery Packs What is a customized lithium battery pack for EVs? A customized lithium battery pack is a

Get Started

FLASH: 10 GWh lithium battery project settles in Inner Mongolia

On October 20th, Youngy Group officially signed an investment cooperation agreement with the government of Wuhai City, Inner Mongolia. Youngy Group will invest Yuan 4.5 billion to

Get Started

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Get Started

Production Process of Battery Modules and

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

Get Started

How are Lithium-ion Battery Packs Manufactured?

Discover the step-by-step process of lithium-ion battery packs manufacturing and learn how these essential components are made. Read the full guide now!

Get Started

Lithium-ion Battery Manufacturing Front to End

Oct 2, 2022 · Process steps applied in the LIB cell production plant, Batteries Journal MDPI (2022) Bullet-point summary Lithium-ion battery (LIB)

Get Started

GBR

Sep 6, 2024 · Even if Mongolia succeeds in developing its first mine in lithium, rare earths, or graphite, the material produced would likely be sent to China for processing.

Get Started

D. KHASHBAT: NEW LITHIUM MINERALIZATION POINTS IN

Aug 15, 2024 · Lithium has emerged as an important mineral in Mongolia''s mining sector, because of increasing global demand. Responding to market trends, both domestic and

Get Started

China''s Largest 1.2GWh Energy Storage Project Powers Up

Apr 18, 2025 · Discover how China''s largest 1.2GWh energy storage project overcame extreme conditions with BYD''s innovative solutions for seamless grid integration.

Get Started

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · This means that during the battery''s operation, lithium ions move from the anode to the cathode through an electrolyte, and then back again when charging. The efficiency of this

Get Started

Youngy Group to Build Li-Ion Battery Plant in Inner Mongolia

Jun 2, 2023 · The first phase of this project is designed to have a production capacity of 20GWh per year for Li-ion batteries. According to the development plan, a 9GWh automated

Get Started

The Manufacturing Process of Lithium Batteries

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in

Get Started

Kim Yang Group is set to manufacture final

May 20, 2024 · South Korea''s Kim Yang Group, renowned for its cylindrical battery production, is expanding its investments to include companies with

Get Started

Lithium Battery Pack Assembly: A

May 6, 2024 · Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations

Get Started

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Get Started

Weilasituo integrated lithium project to start in 2025: Inner Mongolia

Inner Mongolia is expected to have nine new lithium battery supply chain projects by the end of 2025, according to the local ministry of industry and information technology. The integrated

Get Started

4 FAQs about [Mongolia lithium battery pack processing]

Will Mongolia have a battery energy storage system?

A planned battery energy storage system for Mongolia will be the largest of its type in the world and provide a blueprint for other developing countries to follow as they decarbonize their power systems. Mongolia’s coal-dependent energy sector accounts for about two thirds of Mongolia’s greenhouse gas emissions.

Could Mongolia become a battery manufacturing hub?

"Mongolia has lithium assets, Mongolia is building manufacturing facilities, the University of Science and Technology is well-versed in hydrogeology – a joint venture between the public and private sectors could put this manufacturing capability in Mongolia," Haji says - envisioning a greater role for the country in the global battery supply chain.

Is Mongolia's first lithium brine explorer?

Enter ION Energy, Mongolia's first lithium brine explorer. The company (listed on Canada's TSX Venture Exchange) has a license to explore lithium reserves in Sukhbaatar aimag and aims to export high-quality lithium into the burgeoning battery metals Asian market, which would put Mongolia at the forefront of the electric transport revolution.

Are lithium-ion batteries the future of electric vehicles?

(Credit: Ion Energy) According to CEO Ali Haji, the capabilities of lithium-ion batteries and the ever-increasing demand for electric vehicles around the world have recently put Mongolian deposits on the map. "In the early 2000s, lithium batteries began to have a higher adoption rate," Haji explains.

Related Articles

-

Battery pack lithium battery box processing manufacturer

Battery pack lithium battery box processing manufacturer

-

Czech lithium battery pack manufacturer processing

Czech lithium battery pack manufacturer processing

-

Jamaica lithium battery pack OEM processing

Jamaica lithium battery pack OEM processing

-

Lithium battery pack processing in Portugal

Lithium battery pack processing in Portugal

-

Kenya lithium battery battery pack

Kenya lithium battery battery pack

-

West Africa High Rate Lithium Battery Pack

West Africa High Rate Lithium Battery Pack

-

Saint Lucia lithium battery pack

Saint Lucia lithium battery pack

-

Small resistor in lithium battery pack

Small resistor in lithium battery pack

-

Pack lithium battery display cabinet

Pack lithium battery display cabinet

-

12v lithium battery pack terminates discharge

12v lithium battery pack terminates discharge

Commercial & Industrial Solar Storage Market Growth

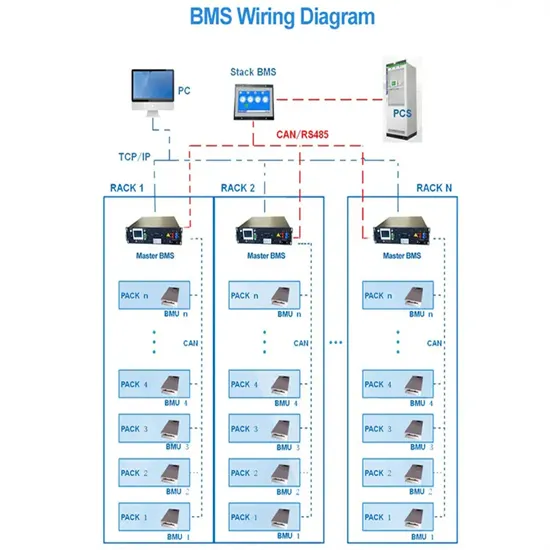

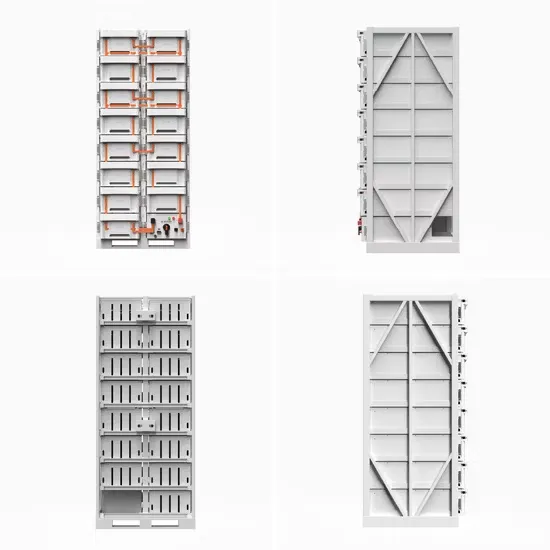

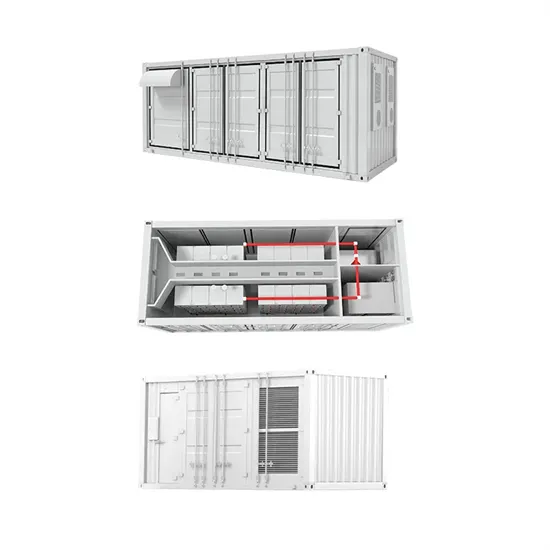

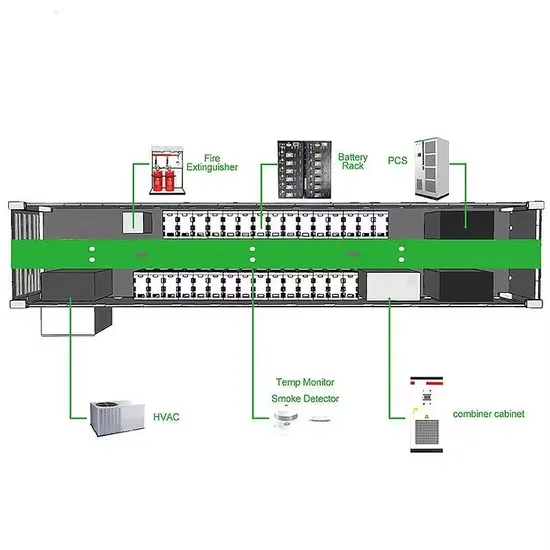

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.