Challenges and opportunities for high-quality battery

Jan 12, 2025 · Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery failure modes and their

Get Started

Top 10 Best Power Banks (Updated Jan 2025)

Jan 9, 2025 · Looking For The Top Power Bank For Your Portable Device? Check Out Our Review of The Best Rated Battery Packs at Lowest Prices On The

Get Started

The Ultimate Guide to Power Packs in China: Types, Trends,

Jan 6, 2025 · From lithium-ion battery packs for electric vehicles to hydraulic power packs for industrial applications, Chinese manufacturers are major players. This guide delves into the

Get Started

8 Best Battery Packs for Power Recliners for

Jul 12, 2025 · That''s where a high-quality battery pack comes in—ensuring uninterrupted use during power outages and allowing placement anywhere in

Get Started

The Best Portable Battery Packs | B&H eXplora

Jul 8, 2024 · A buying guide comprised of the best portable battery packs with highlights from accessory mainstays like Anker and Belkin.

Get Started

Automotive Battery Pack Standards and Design

Mar 18, 2025 · Battery packs are key components of electric vehicles (EVs) because they operate as the main power supply. Despite recent advancements, further improvements are required

Get Started

How to Evaluate the Quality of a Battery: A Comprehensive

Discover how to evaluate battery quality effectively with our comprehensive guide. Learn key factors, testing methods, and tips for choosing reliable batteries.

Get Started

The best portable chargers of 2025, tried and

Jul 8, 2025 · We tested more than 10 of the most popular portable chargers to find the one that''s best suited for your bag on your next trip.

Get Started

Lithium Battery Pack Assembly: A

May 6, 2024 · Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations

Get Started

Leading Battery Pack Manufacturers in China: A

May 4, 2025 · Sunwoda specializes in producing high-quality battery packs that power everything from smartphones to EVs. Their expertise in lithium-ion

Get Started

A Leading Expert in Lithium-based Renewable

Superpack provides fully-integrated products & solutions for lithium-based renewable energy applications. We build a clean world with you!Portable

Get Started

Be Power Co, LTD|BEPOWER energy|customize

Be Power Co, LTD is focusing on lithium battery and High rate cells. Our team came from CALB. We are producing and providing high rate LFP batteries,and

Get Started

Best power banks 2024: Reviews and buying

Nov 22, 2023 · As we use the DROK load tester to drain the pack of power, we are able to test against a battery''s stated maximum current, and verify that

Get Started

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Get Started

[2503.12566] Automotive Battery Pack Standards and Design

Mar 16, 2025 · Also, advances in energy density and battery capacities make advancements in enhancing the electric vehicle''s range beyond 1000 km per charge. Key factors such as

Get Started

The 7 Best Power Banks of 2025

Mar 13, 2025 · Charging Time Power output determines the overall power of your portable battery pack. In other words, the stronger the power output, the faster

Get Started

Best Battery Packs to Stay Charged in 2025: Top

Discover the best battery packs for 2025. Explore our top picks and learn what to look for before buying to ensure your devices stay charged anytime, anywhere.

Get Started

Battery Pack Design: Efficient & Safe Energy

Mar 15, 2025 · Learn how to design a high-performance battery pack with the right cell configuration, cooling system, and safety features.

Get Started

Highest Capacity Battery Packs: What You Need

Mar 5, 2025 · When it comes to high-capacity battery packs, the demand has skyrocketed in recent years. People constantly search for the highest battery

Get Started

What is Power Battery Pack Test System?

Jul 9, 2024 · Batch consistency check: Through systematic testing, to ensure the consistency of battery pack performance and safety in mass production. In

Get Started

The Best Portable Chargers and Power Banks for

May 28, 2025 · Our power bank picks allow you to pack hours of extra battery life in a pocket or purse to charge a phone, tablet, or other small electronic device.

Get Started

Exploring Battery Testing Standards: A

Apr 8, 2024 · Delve into the world of battery testing standards with Linkotest. Discover essential methodologies, standardsto ensure battery safety and

Get Started

Pack Team Power » Battery pack manufacturer

Pack Team Power local in Dongguan Guangdong province, the company has gathered a strong group with development, production and quality control

Get Started

Battery Pack Manufacturing Process

Mar 15, 2025 · Battery packs power everything from electric vehicles to smartphones. But have you ever wondered how they''re made? The battery

Get Started

Power Battery Pack Design Process

Jun 28, 2024 · Determine the production process flow, ensuring production quality and stability of the battery pack. Implement quality control measures to monitor key parameters and quality

Get Started

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step

Get Started

Introduction to Power Battery Packs-JONVER

Apr 10, 2025 · Pros: Strong structural integrity, easier assembly, and robust cell protection. Cons: Low space utilization, higher module hardware costs (~15% of total), lower energy density, and

Get Started

6 FAQs about [Power battery pack quality]

What are the electrical specifications of a battery pack?

The electrical specifications of the battery pack as the source of traction energy and power are explained in this section. The battery pack should be able to provide the required power and energy for a predetermined lifetime or operational cycle.

What should be considered in a battery pack design?

Hence, all requirements and regulations should be considered in pack design. There are three types of electrical interfaces for a battery pack: power, signal, and MSD. The battery pack may have one or more main outputs to be connected to the loads and charger.

What makes a good battery pack?

The battery pack should be able to provide the required power and energy for a predetermined lifetime or operational cycle. In addition, the capacity must be within the specified values during different operating conditions and should remain stable during the lifecycle with limited aging factors.

What should a battery pack report?

The battery pack shall report its state of charge and the status of the system components to the vehicle controller. In addition, in some cases, such as an overcurrent, the pack should be able to act appropriately. A combination of cells constitutes a module and a combination of modules forms a pack.

What is a battery pack?

The battery pack is an independent subsystem at the vehicle level that was tested separately. The unit should be able to operate under different electrical and environmental conditions considering safety concerns and regulations. Hence, the battery unit is enclosed by a metallic enclosure that can survive different test cases such as vibrations.

What are the charging and discharging requirements of a battery pack?

The charging and discharging requirements of the battery pack are directly related to the power demand required by the electric motors and the charging time. The battery pack design shall be such that could meet the required max power in traction and regeneration modes. In addition, the charging power is a critical factor for end users.

Related Articles

-

New energy vehicle power battery pack price

New energy vehicle power battery pack price

-

Lithium battery pack power generation

Lithium battery pack power generation

-

Belarusian power tool lithium battery pack 60v

Belarusian power tool lithium battery pack 60v

-

How many V does a 12V30A lithium battery pack lose power

How many V does a 12V30A lithium battery pack lose power

-

Costa Rica Power Lithium Battery Pack

Costa Rica Power Lithium Battery Pack

-

Power lithium battery pack is exhausted

Power lithium battery pack is exhausted

-

Is it useful to replenish power with a lithium battery pack alone

Is it useful to replenish power with a lithium battery pack alone

-

Battery pack as outdoor power source

Battery pack as outdoor power source

-

Lithium battery pack quality inspection items

Lithium battery pack quality inspection items

-

Huawei Swiss cylindrical power battery pack

Huawei Swiss cylindrical power battery pack

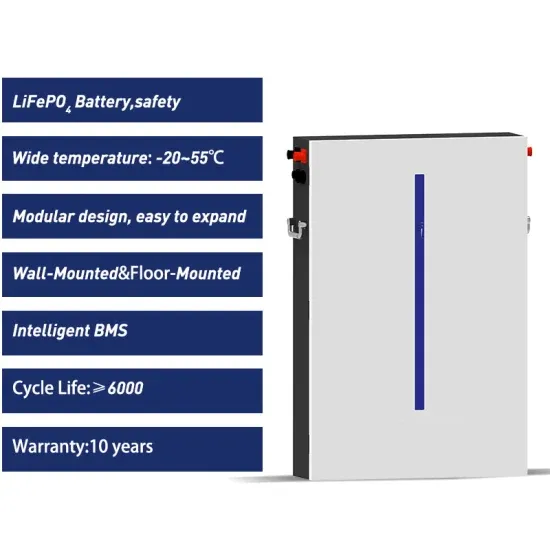

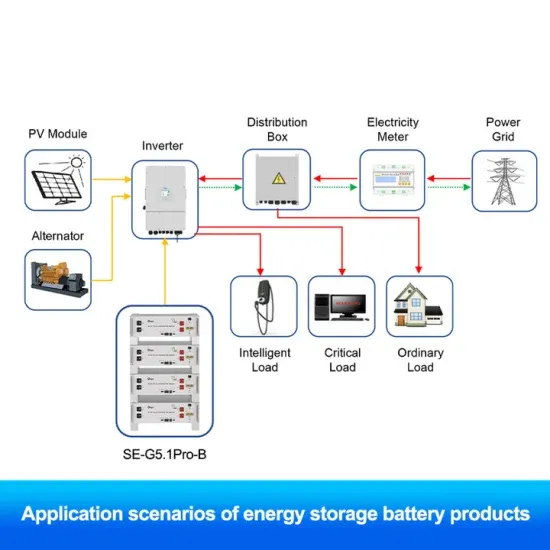

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.