What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · The most important determinant is the crystalline silicon technology in photovoltaic modules, followed by the protection of photovoltaic glass in photovoltaic modules. Photovoltaic

Get Started

(PDF) Silicones for Photovoltaic Encapsulation

Jan 1, 2008 · Internal evaluations at Dow Corning and with select external partners have shown that very efficient solar cells using silicones as the

Get Started

Window-Integrated PV Glass: The Future of Solar

Feb 19, 2025 · Photovoltaic (PV) glass stands at the forefront of sustainable building technology, revolutionizing how we harness solar energy in modern

Get Started

How is optical silicone applied? | XJY SILICONES®

Optical silicone has excellent transparency, flexibility, and adjustable parts, in various fields from optics and photonics to electronics and cattle technology have great potential. Optical silicone

Get Started

Application of silicone adhesive sealant in solar photovoltaic

May 18, 2024 · Therefore, it is mainly used for sealing building glass and ceramics. It is commonly known as glass glue. It is rarely used in industry; the amide small molecule by-product

Get Started

AMORPHOUS SILICON PHOTOVOLTAIC GLASS

2 days ago · Amorphous Silicon Photovoltaic glass can range from fully opaque, which provides higher nominal power, to various levels of visible light

Get Started

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

Get Started

Can You Use Silicone on Glass? A Complete Guide for Your

Silicone is a go-to material for many DIY projects, but can you really use it on glass? Whether you''re sealing a window, creating a decorative piece, or repairing a broken item,

Get Started

How Silicone Is Used in Solar Cells | NenPower

Oct 16, 2024 · Silicone acts as a crucial interface between the solar cells and their operating environment. Its primary purpose involves encapsulating the

Get Started

CRYSTALLINE SILICON PHOTOVOLTAIC GLASS

2 days ago · Crystalline silicon or (c-Si) is the crystalline forms of silicon, either polycrystalline silicon (poly c-Si), or monocrystalline silicon (mono c-Si). It

Get Started

Transparent Solar Panels: Reforming Future

Feb 29, 2020 · What are transparent solar panels? Photovoltaic glass is probably the most cutting-edge new solar panel technology that promises to be a game

Get Started

Improving the light transmission of silica glass using silicone

Sep 15, 2024 · The anti-reflection (AR) technology currently used in photovoltaic (PV) glass has reached its operational limit as the refractive index of existing materials cannot be lowered

Get Started

Glass Application in Solar Energy Technology

Apr 28, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and

Get Started

Silicone Membrane For Solar Panel Lamination

Sep 9, 2023 · Expert guidance to PV lamination success! Learn how the revolutionary use of silicone membrane will take your solar panel projects to

Get Started

Onyx Solar, Building Integrated Photovoltaics

2 days ago · Onyx Solar: Leader in Building Integrated PV Solutions. Custom Photovoltaic Glass for energy generation that enhances energy efficiency and

Get Started

Application of Silicone Sealant in Solar Modules

Jul 5, 2022 · At Guibao, our GUIBAO 888A Silicone Sealant for Solar Modules goes through some of the most rigorous tests before being passed for

Get Started

The role of silicone resin in photovoltaic panels

Can silicone encapsulants be used for photovoltaic modules? These properties make them ideal candidatesas encapsulants for photovoltaic modules. Internal evaluations at Dow Corning and

Get Started

What about optical silicone in the photovoltaic industry?

Silicone resin in the photovoltaic industry, such as surface glass using glass fibers as well as silicone resin coating to replace the flexible materials in the photovoltaic industry''s rapid

Get Started

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable,

Get Started

Double-glass PV modules with silicone encapsulation

May 21, 2024 · In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is

Get Started

SILICONES FOR SOLAR APPLICATIONS

Silicones can also be used for the assembly of solar collectors, e.g. for bonding the front glass to the frame structure. WACKER silicone rubber grades are ideal for bonding the PV laminate,

Get Started

Double-glass PV modules with silicone encapsulation

May 21, 2024 · ABSTRACT Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Get Started

Transparent solar panels: an expert guide [UK,

Jul 23, 2024 · Transparent solar panels, also known as solar glass, are see-through photovoltaic (PV) technologies that can generate electricity from

Get Started

PV module recycling tech based on

Apr 4, 2025 · The materials can then be used to extract silicon (Si) and silver (Ag) through downstream chemical processes, while the glass, Cu/Al/Ag contacts

Get Started

Which Semiconductors Are Used in Solar Cells

May 16, 2024 · Explore the vital role of semiconductors used in solar cells for efficient energy conversion and the advancement of photovoltaic technology.

Get Started

Application of silicone adhesive sealant in solar photovoltaic

May 18, 2024 · Architectural practice has proven that silicone sealant can withstand the test and is therefore the most suitable sealant for solar photovoltaic modules. The common silicone

Get Started

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

Get Started

Low Temperature Solar Cell Encapsulation with Novel

Mar 29, 2023 · A low temperature or even room temperature lamination process enables faster manufacturing and is therefore advantageous for BIPV applications. Silicone encapsulation of

Get Started

What is photovoltaic glass? –

Apr 15, 2023 · Photovoltaic glass is also being used in transportation applications in the United Kingdom. It can be used to power electric vehicles, reduce

Get Started

6 FAQs about [Can silicone be used in photovoltaic glass ]

Can silicone be used for solar panels?

Silicones can also be used for the assembly of solar collectors, e.g. for bonding the front glass to the frame structure. WACKER silicone rubber grades are ideal for bonding the PV laminate, usually comprising a front glass, encapsulation films in front of and behind the solar cells, and a back-sheet, to the aluminum frame.

Can silicone encapsulants be used for photovoltaic modules?

These properties make them ideal candidates as encapsulants for photovoltaic modules. Internal evaluations at Dow Corning and with select external partners have shown that very efficient solar cells using silicones as the encapsulant can be assembled and show very good reliability.

What is the difference between a silicone and a photovoltaic module?

Soldering tags for electrical components Whereas, in standard photovoltaic modules, silicones are limited to bonding and potting ap-plications, their properties make them suitable for a wider range of applications in customized solar panels (e.g. building integrated photovol-taics), where they play an essential role in the generation of energy.

Can a silicone solar cell encapsulant be used at room temperature?

In this work we introduce a new type of silicone solar cell encapsulant which enables lamination at temperatures down to room temperature, we describe the lamination process and show results at blank laminate and mini-module levels, after lamination and also after accelerated ageing.

What material was used to make a solar cell?

The glass was 4 mm float glass, the solar cell was a 156 mm multicrystalline Si solar cell, tabbed and attached with bussing ribbons. The dam material was a silicone hot melt product, DOWSILTM 2400 Silicone Assembly Sealant. This type of material is solid as delivered, but becomes a viscous liquid when heated up.

What type of rubber is best for solar panels?

WACKER silicone rubber grades are ideal for bonding the PV laminate, usually comprising a front glass, encapsulation films in front of and behind the solar cells, and a back-sheet, to the aluminum frame. Silicones are also a reliable solution to fix system components, such as junction boxes.

Related Articles

-

Silicon used in photovoltaic glass

Silicon used in photovoltaic glass

-

Gases used in photovoltaic glass

Gases used in photovoltaic glass

-

Can photovoltaic panels be used through glass

Can photovoltaic panels be used through glass

-

Can the photovoltaic glass that costs ten yuan be used

Can the photovoltaic glass that costs ten yuan be used

-

Photovoltaic glass is widely used

Photovoltaic glass is widely used

-

Venezuela Future Photovoltaic Glass Production Plant

Venezuela Future Photovoltaic Glass Production Plant

-

Grenada Photovoltaic Glass House BESS Price

Grenada Photovoltaic Glass House BESS Price

-

The most transparent photovoltaic glass

The most transparent photovoltaic glass

-

Photovoltaic panel glass thickness

Photovoltaic panel glass thickness

-

Which glass photovoltaic module manufacturer is the best in Uzbekistan

Which glass photovoltaic module manufacturer is the best in Uzbekistan

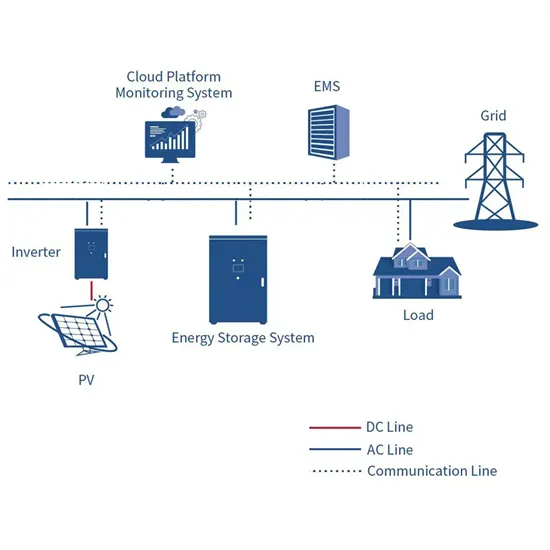

Commercial & Industrial Solar Storage Market Growth

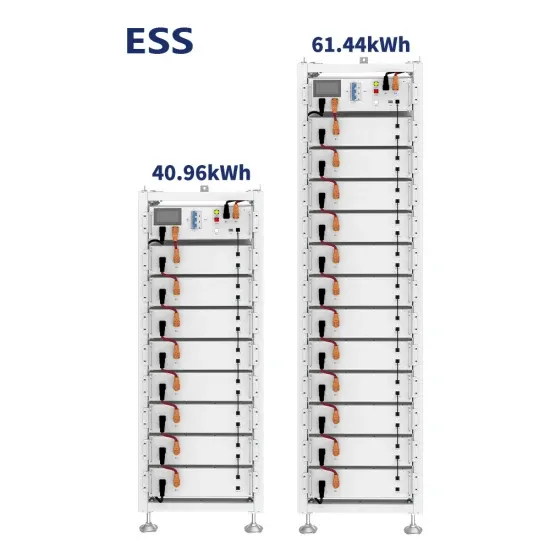

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.