Effectively and completely separating the waste crystalline

Jun 22, 2025 · The PV glass is removed beforehand to prevent the physical mixing of glass with the cells, which complicates their separation. The backsheet is also removed before

Get Started

FLUORINATED GREENHOUSE GASES IN PHOTOVOLTAIC

Nov 2, 2007 · Some fluorinated gases (F-gases) which are used, or considered to be used, in crystalline silicon photovoltaic solar cell and film silicon module manufacturing have a very

Get Started

Role of NaCl on structural, optical and mechanical properties

May 1, 2025 · Solar photovoltaic glasses are waste materials after prolonged use and broken during the operations of solar cells. These waste glasses are recycled and have properties

Get Started

Hazardous Materials Used In Silicon PV Cell Production: A

The solar PV industry must address these issues immediately, or risk repeating the mistakes made by the microelectronics industry.

Get Started

Improving the light transmission of silica glass using silicone

Sep 15, 2024 · The anti-reflection (AR) technology currently used in photovoltaic (PV) glass has reached its operational limit as the refractive index of existing materials cannot be lowered

Get Started

Experimental investigation on the combustion performance

Jun 15, 2025 · Experiments show PET backsheet and EVA film promote fire, while fire-resistant tempered glass improves fire resistance and reduces flammable materials. In pursuit of

Get Started

Welcome to SG Facade Engineering Pte Ltd

Dec 15, 2021 · Photovoltaic (PV) Glass System Building-Integrated Photovoltaics (BIPV) is the integration of solar cells into the building envelope. Photovoltaic

Get Started

Analysis of Material Recovery from Silicon Photovoltaic

Finally, the high efficiency and quality of glass separated through the FRELP processes could be used for high quality applications (e.g. glass for the production of new PV panels).

Get Started

Investigation of combustion hazards of glass photovoltaic

May 15, 2025 · The main toxic gaseous emissions from combustion include carbon monoxide, carbon dioxide, sulfur dioxide, and hydrogen cyanide, with their instantaneous concentrations

Get Started

Essential Gases for Photovoltaic Panel Manufacturing: What

The photovoltaic industry relies heavily on specialized gases at various production stages – from silicon purification to final cell encapsulation. Let''s break down the must-have gases and their

Get Started

Special gases are used for photovoltaics, solar energy, LED

Electronic specialty gases, abbreviated as electronic specialty gases, refer to specialty gases used in consumer display panels, semiconductors, photovoltaics, and other electronic

Get Started

Avaada Talks About the Role of Specialty Gases

Dec 16, 2024 · Specialty gases enhance deposition, doping, and cleaning in solar PV manufacturing. Key gases include silane, hydrogen, nitrogen trifluoride,

Get Started

Experimental study on burning and toxicity hazards of a PET

Mar 1, 2020 · Currently, photovoltaics have been used on a large scale for commercial and civilian use. Aging short circuit, fire and other reasons will bring great security risks. In this paper, an

Get Started

Insights into the Encapsulation Process of Photovoltaic

Aug 14, 2024 · various additives formulated in EVA, in the TDU. Samples of 5 mg of a During the PV module encapsulation complex chemical reactions are expected commercially available

Get Started

Solar glass/Photovoltaic glass classification

Aug 27, 2019 · Solar glass/Photovoltaic glass classification As new energy,solar glass is now widely used in building curtain wall, photovoltaic roof, sunshade,

Get Started

Photovoltaics International journal. Gas abatement for

May 21, 2024 · AbStRAct This paper presents and discusses the merits of layout, systems and options for exhaust treatments in PV cell production. Such treatments usually comprise central

Get Started

Investigation of combustion hazards of glass photovoltaic

May 15, 2025 · Abstract At present, the application scale of glass panel photovoltaic modules worldwide is rapidly increasing, and they are widely used in centralized and distributed

Get Started

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged due to growing interest in green energy. This article explores types like ultra-thin, surface

Get Started

PV Solar Cell Manufacturing Process

Solar Module Lamination: A Critical Step in PV Manufacturing Solar photovoltaic lamination stands as an important step in the solar module manufacturing

Get Started

Powering adoption of solar energy | Linde

Explore the role of ultra-pure electronics gases, wet chemicals and specialist materials from Linde in photovoltaic production processes as the role of solar

Get Started

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

Get Started

Semiconductor | Electronic Special Gas, 2025

The 2021, electronic special gas is used in 43% of integrated circuits, followed by display panels, accounting for 21%, led and PV accounted for 13% and 6%,

Get Started

Why U-Value Matters: Window-Integrated PV

Jan 27, 2025 · The U-value of windows stands as a critical performance metric in modern architectural design, measuring heat transfer through glazing systems

Get Started

Toxic Materials Used in Thin Film Photovoltaics

Jan 8, 2020 · Thin film PV (TFPV) technology contains a higher number of toxic materials than those used in traditional silicon PV technology, including

Get Started

Photovoltaic Glazing Technology: Impact

Oct 9, 2023 · Unveiling Photovoltaic Glazing Photovoltaic glazing is a breakthrough in renewable energy and green technology, marking a

Get Started

Gas Analysis in Photovoltaic Cell Production

Here are some examples of gases and liquid chemicals used in PV manufacturing: Silane (SiH4): a colorless, flammable gas that is used as a source of silicon in the production of crystalline

Get Started

Fluorinated Greenhouse Gases in Photovoltaic Module

Abstract Some fluorinated gases (F-gases) which are used, or considered to be used, in crystalline silicon photovoltaic solar cell and film silicon module manufacturing have a very

Get Started

Temperature-dependent water vapour and

Most photovoltaic (PV)-modules have polymeric materials as encapsulants and back sheets. Usually these materials are not water vapour-tight and air-tight,

Get Started

The manufacturing of photovoltaic glass

Photovoltaic glass is a new type of material based on solar power generation. It is composed of solar cells and glass, which can convert solar energy into electrical energy, effectively

Get Started

6 FAQs about [Gases used in photovoltaic glass]

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Why is glass used in PV cells?

Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency.

What are glass photovoltaic panels?

Glass photovoltaic panels are multilayer composite materials consisting of various polymers.

What oxides are used in solar glass?

In solar glass formulations, the key compo- magnesium oxide (MgO). These oxides are widely used because of their abundant they provide to the glass matrix. process. The resulting glass exhibits the mechanical and optical properties necessary transmission, and thermal resistance. The predominant use of these basic oxides solar technologies.

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

Why is glass used in solar panels?

transmission and efficiency. It is commonly used in high-performance solar panels to optimize light absorption and increase overall cell efficiency [40, 41]. chemical composition of the glass. The synthesis method influences the glass micro-

Related Articles

-

Silicon used in photovoltaic glass

Silicon used in photovoltaic glass

-

Can silicone be used in photovoltaic glass

Can silicone be used in photovoltaic glass

-

Photovoltaic glass is widely used

Photovoltaic glass is widely used

-

Is photovoltaic glass a high-energy project

Is photovoltaic glass a high-energy project

-

Berlin Photovoltaic Glass Application

Berlin Photovoltaic Glass Application

-

Photovoltaic panel glass thickness

Photovoltaic panel glass thickness

-

Prospects of Photovoltaic Tempered Glass Industry

Prospects of Photovoltaic Tempered Glass Industry

-

Glass and silicon wafers in the photovoltaic industry

Glass and silicon wafers in the photovoltaic industry

-

Rome builds photovoltaic glass project

Rome builds photovoltaic glass project

-

Serbia photovoltaic glass greenhouse customization

Serbia photovoltaic glass greenhouse customization

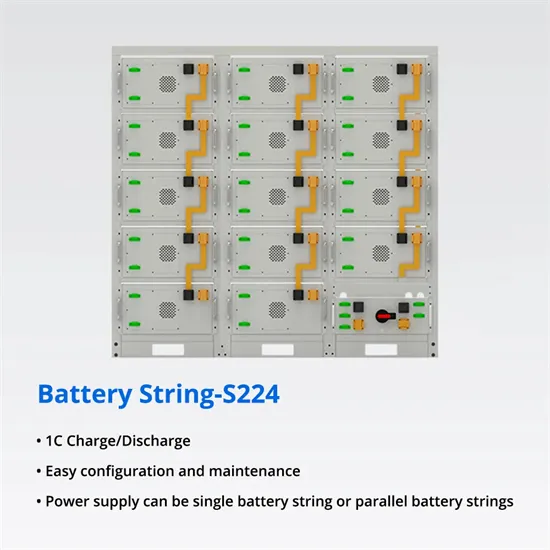

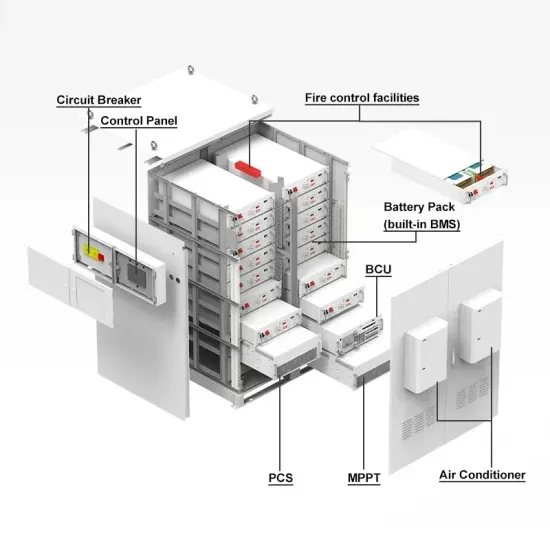

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.