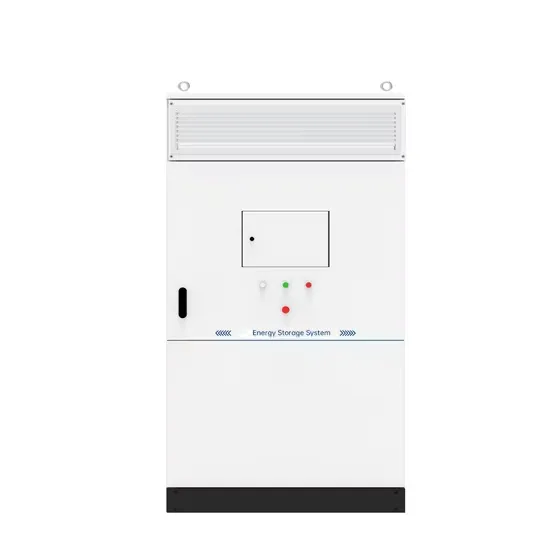

Battery Cabinet

Mar 21, 2023 · Lithium Battery Cabinet SmartLi 3.0 Scenario where SmartLi 3.0 lithium battery cabinets are deployed outside the smart module: One integrated UPS can connect to a

Get Started

Updated Codes and Standards for Stationary Batteries:

Explore the comprehensive addendum to Eagle Eye Power Solutions'' white paper on codes and standards applicable to stationary batteries and their chargers. This detailed update delves

Get Started

Specification for Batteries (IEC)

Jan 18, 2021 · For cabinets designed for flooded batteries, a chemical resistant spill containment system sized to contain the electrolyte volume from a cell shall be provided at the base of the

Get Started

1926.441

Aug 15, 2025 · Batteries of the unsealed type shall be located in enclosures with outside vents or in well ventilated rooms and shall be arranged so as to prevent the escape of fumes, gases, or

Get Started

Codes and Standards Governing Battery Safety

Aug 19, 2025 · Discover the key codes and standards governing battery safety and compliance in building and fire regulations. Learn about the various

Get Started

Ventilation and Thermal Management of Stationary

Jan 10, 2023 · Introduction The Institute of Electrical and Electronics Engineers, Inc. (IEEE) Stationary Battery Committee was approached by the American Society for Heating

Get Started

Battery Spill Containment

It also requires an approved method, capable of neutralizing a spill from the largest lead-acid battery. In response to these new requirements, Exponential

Get Started

Li118

Designed for facilities handling rechargeable batteries—such as lithium-ion, nickel-cadmium, and lead-acid units—our cabinets provide a centralized solution for both secure storage and safe

Get Started

How to calculate that your power system is

Jul 13, 2022 · Gassing and Ventilation of Lead-acid Batteries in Standalone Power Systems. How to calculate that your power system is adequately

Get Started

What are the OSHA Requirements for Battery

Oct 16, 2023 · The rationale behind this is that certain storage batteries, especially lead-acid batteries, can release hydrogen gas during charging.

Get Started

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards. 1. Space

Get Started

LI145

Description Protect your facility and your team with Securall''s purpose-built Battery Charging Cabinets —engineered for the safe storage and charging of lithium-ion, lead-acid, and other

Get Started

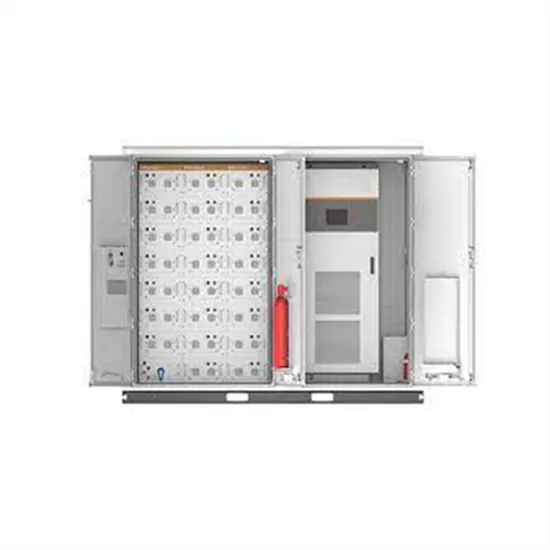

Standard Specifications for Lithium Battery Energy

AZE''''s 42U indoor battery rack cabinets painted with polyester powder, suitable for different brands lithium-ion batteries, it is the perfect solution for housing your Low Voltage Energy

Get Started

How to calculate battery room hydrogen ventilation

How to calculate hydrogen ventilation requirements for battery rooms.For standby DC power systems or AC UPS systems, battery room ventilation is calculated in accordance to EN 50272

Get Started

Battery cabinets for uninterruptible power supplies

The ENERPOWER battery cabinets are designed to contain hermetic lead acid electric accumulator batteries, and comply with the safety criteria of the current CEI 21-6 / December

Get Started

Battery cabinets | Legrand Data Center Solutions

Aug 18, 2025 · Legrand offers universal battery cabinets for all three-phase Legrand Uninterruptible Power Supply (UPS) models ranging from 10kVA to 800kVA power output.

Get Started

Hydrogen Management in Battery Rooms

2 days ago · Best practice standards such as IEEE documents and fire code state that you must deal with hydrogen in one of two ways: 1) Prove the hydrogen

Get Started

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Learn the requirements for VRLA batteries and how to be compliant with current regulation. Also learn the various rack compliance requirements and best practices including

Get Started

IP55 Outdoor Lead Acid Battery Cabinet

AZE''s outdoor battery cabinet includes standard features with battery support, security and sealing abilities and reversible racking rails, 500W to 5000W air

Get Started

Specification for Batteries (IEC)

Jan 18, 2021 · Scope This document specifies the minimum requirements for batteries and battery installations. In general, the requirements and definitions are specified for lead-acid and nickel

Get Started

VRLA Installation and Commissioning

Nov 6, 2018 · IEEE Standard 1187 establishes the recommended practices for the design and installation of valve-regulated lead-acid (VRLA) batteries.

Get Started

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

Get Started

Regulatory Compliance and Standards for Industrial Lead-Acid Batteries

6 days ago · Regulatory compliance and standards for industrial lead-acid batteries are essential for ensuring safety, environmental protection, and efficient operation. By adhering to these

Get Started

BATTERY CABINETS CATALOGUE

Jun 4, 2025 · The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries. The construction characteristics of the

Get Started

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

Get Started

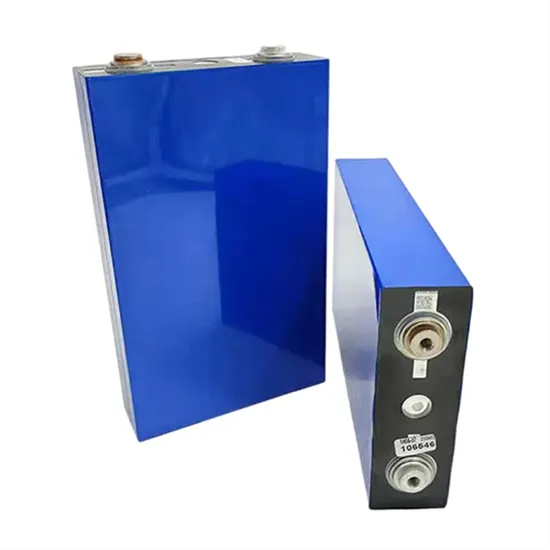

UL-1973 Certification and Battery Components

Apr 24, 2023 · ESS deployment is gaining ground as the cost of lithium-ion bateries continues decreasing due to newer designs and more eficient manufacturing. Silicon and lead acid

Get Started

6 FAQs about [Lead-acid battery cabinet standard]

Which accumulator batteries are included in the cabinets covered by the technical specification?

The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries.

What is a VRLA battery cabinet?

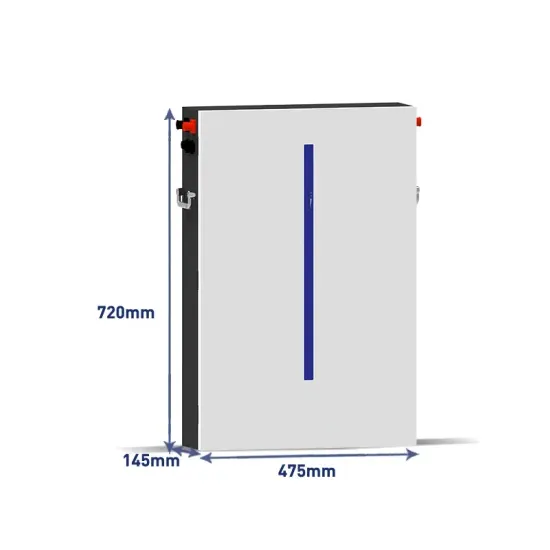

They are designed to accommodate standard Valve Regulated Lead Acid (VRLA) batteries with a capacity range of 24Ah to 105Ah (C10). The battery cabinets are available in five different mechanical dimensions.

What are the requirements for ventilation of battery rooms or cabinets?

Ventilation of battery rooms or cabinets shall be in accordance with with National Regulation and/or IEC/EN 62485-2. Internal resistance can be important to the equipment design and operation. The manufacturer shall state the value of internal resistance for a new battery.. This item is covered by chapter 6.3 of IEC/EN 60896-21 and -22.

What are the requirements for a battery cabinet & enclosure?

Cabinets shall have natural or forced ventilation as specified. The ventilation fans shall be installed with a redundant (N+1) configuration. Within the cabinet or enclosure, batteries shall be accessible to permit inspection and maintenance of cells without any safety risk to personnel.

How many batteries can a battery cabinet support?

The battery cabinets are available in five different mechanical dimensions. They can facilitate multiple combinations of batteries, up to 63 battery blocks, connected in series and parallel configurations with positive, negative, and mid-point poles. The battery cabinets also support a maximum Direct Current (DC) voltage of 800Vdc.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

Related Articles

-

How much does a standard battery cabinet weigh and how much does it cost

How much does a standard battery cabinet weigh and how much does it cost

-

Lead-acid battery cabinet management

Lead-acid battery cabinet management

-

Niger outdoor lead-acid battery cabinet

Niger outdoor lead-acid battery cabinet

-

How to deal with lead-acid battery cabinet pulp

How to deal with lead-acid battery cabinet pulp

-

Lead-acid battery cabinet safety solution

Lead-acid battery cabinet safety solution

-

Lead-acid battery cabinet capacity

Lead-acid battery cabinet capacity

-

What is the standard storage location of lithium battery station cabinet

What is the standard storage location of lithium battery station cabinet

-

Lead-acid battery cabinet color

Lead-acid battery cabinet color

-

Which base stations are covered by the lead-acid battery cabinet

Which base stations are covered by the lead-acid battery cabinet

-

Standard storage location base station for lithium battery station cabinet

Standard storage location base station for lithium battery station cabinet

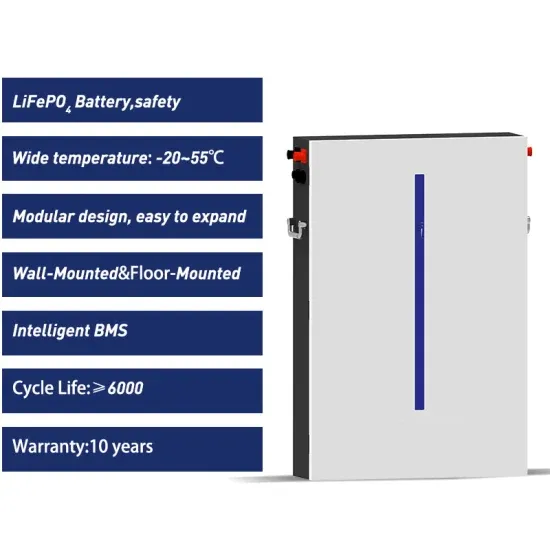

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

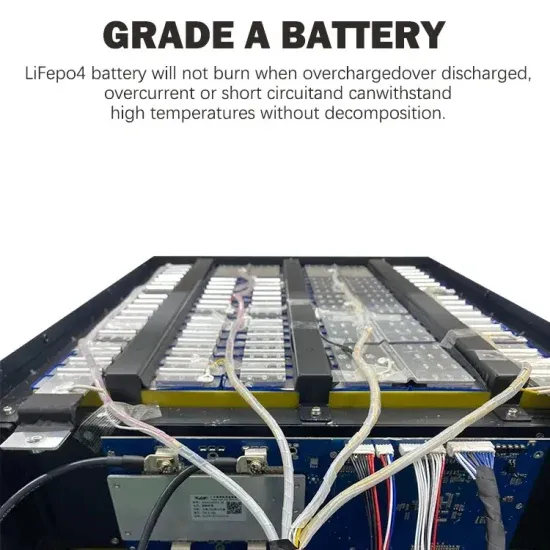

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.