Solar Cells on Multicrystalline Silicon Thin Films Converted

Sep 2, 2024 · Alternatively, thin-film multicrystalline (mc) silicon on glass can help to save both energy and material consumption compared to full-silicon-wafer technologies. Competitive PV

Get Started

Multicrystalline Solar Cells for PV Manufacturers

5 days ago · Trusted by PV manufacturers worldwide, our high-efficiency multicrystalline solar cells are engineered to meet the evolving requirements of

Get Started

CO2 EMISSIONS OF SILICON PHOTOVOLTAIC MODULES

Sep 27, 2022 · In general, the CO2 emissions of PV systems are significantly lower than those of conventional energy generation using, for instance, coal, but there are considerable

Get Started

Characterization of Multicrystalline Silicon Modules with

As it is considered economically favorable to serially connect modules to build arrays with high system voltage, it is necessary to explore potential long-term degradation mechanisms the

Get Started

Glass-Glass PV Modules

4 days ago · Double-glass modules boast increased reliability, especially for utility scale PV projects. These include better resistance to higher temperatures,

Get Started

Multifunctional coatings for solar module glass

Apr 22, 2024 · Studies have been conducted on MLCs in terms of optical, microstructure, mechanical, and durability properties compared with

Get Started

Corrosion effects in bifacial crystalline silicon PV modules

Jul 1, 2023 · This study addresses the influence of different encapsulation materials on performance losses in bifacial PV modules after extended damp heat testing.

Get Started

Life Cycle Assessment of Crystalline Silicon Photovoltaic Module

The objective of this study is to complete a life cycle assessment (LCA) of a novel technology that separates the crystalline silicon (c-Si) photovoltaic (PV) module front glass from the backsheet

Get Started

Reflection optimization of a multicrystalline solar cell

Oct 25, 2023 · In this paper we study the surface reflection of a photovoltaic module. The antireflection layer based on silicon nitride SiNx, is deposited by PECVD technique and

Get Started

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Introduction Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV

Get Started

Moisture induced degradation in field-aged multicrystalline

Aug 15, 2023 · Moisture ingress is one of the key fault mechanisms responsible for photovoltaic (PV) devices degradation. Understanding moisture induced degradation (MID) mechanisms in

Get Started

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Get Started

Modélisation des échanges convectifs dans le conduit

Dec 18, 2023 · The cells connected in serial and parallel are encapsulated in glass and EVA (ethylene-vinyl acetate) structure to get the photovoltaic module [6].

Get Started

Presentation

Jun 1, 2023 · Currently, glass-glass modules (~15.2 kg/m2) are about 35-40% heavier per unit area than glass-backsheet modules (~11.3 kg/m2)* Almaden advertises 2mm double glass

Get Started

Crystalline Silicon Module

5.4.1 Crystalline silicon modules Crystalline silicon (c-Si) modules dominate the PV market with a 95% share [73]. The cells are available in multicrystalline (multi-Si) and mono-crystalline

Get Started

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

Get Started

Effect of Temperature and Humidity on the

Jan 1, 2013 · This study investigates seasonal performance and assesses the annual degradation rates (RD), of three types of silicon-based PV module

Get Started

Cracking Down on PV Module Design: Results from

Sep 5, 2023 · The multicrystalline PV module above (right) showed significant cell cracking and inactive areas following MSS, whereas the monocrystalline module (left) is unafected.

Get Started

Top 5: Factors Responsible for Glass Breakage in

Mar 13, 2025 · Glass breakage is a growing concern for the solar power plant operators. With the trend towards double glass sided modules as seen in

Get Started

Luminescent down-shifting natural dyes to enhance photovoltaic

Aug 1, 2020 · The short wavelength photons (below 500 nm) of the solar spectrum are under-utilized in multicrystalline silicon (mc-Si) solar modules because of their high surface

Get Started

A comparative life-cycle assessment of photovoltaic

Jan 1, 2018 · Finally, our study also demonstrates that long-term PV module reliability has great impacts on the environmental performance of PV technologies. The environmental benefits (in

Get Started

Folder1_Page1.CDR

May 21, 2021 · HighestQualityWorldwide BISOL PRODUCTS BISOL produces high quality mono- and multicrystalline silicon photovoltaic modules designed for both commercial and residential

Get Started

Review of issues and opportunities for glass

Low-iron sand is required for PV glass production, to make the glass highly transparent and reduce the absorption of solar energy. Additionally, glass

Get Started

European Glass-Glass Photovoltaic Modules Are

Sep 23, 2021 · In a new study, researchers at the Fraunhofer Institute for Solar Energy Systems ISE have calculated that silicon photovoltaic modules

Get Started

Multifunctional coatings for solar module glass,Progress in

Apr 22, 2024 · This paper aims to develop a non-porous multilayer coating (MLC) that is more durable and will act as a spectrally selective filter for solar modules. Studies have been

Get Started

Characterization of front contact degradation in

Jan 1, 2022 · Abstract Reliability and durability tests play a key role in the photovoltaic (PV) industry by minimizing potential failure risks for both existing and new cell and module

Get Started

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Get Started

Liquid Glass for Photovoltaics: Multifunctional

Aug 30, 2019 · In this work, we demonstrate for the first time two showcases of texturing fused silica front cover glass, using the facile liquid glass technique:

Get Started

Modélisation des échanges convectifs dans le conduit

The cells connected in serial and parallel are encapsulated in glass and EVA (ethylene-vinyl acetate) structure to get the photovoltaic module [6]. The optical parameters (thickness and

Get Started

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The aim of this chapter is to present and explain the basic issues relating to the construction and manufacturing of PV cells and modules from c-Si. This includes the basic

Get Started

6 FAQs about [Lome multicrystalline photovoltaic module glass]

Are glass-glass PV modules a good choice?

Glass-glass PV modules (b) do not require an aluminum frame and therefore have a lower carbon footprint than PV modules with backsheet (a). Although photovoltaic modules convert sunlight into electricity without producing emissions, PV-generated solar energy does produce CO2 emissions during production, transport and at the end of module life.

Is a non-porous multilayer coating a spectrally selective filter for solar modules?

This paper aims to develop a non-porous multilayer coating (MLC) that is more durable and will act as a spectrally selective filter for solar modules. Studies have been conducted on MLCs in terms of optical, microstructure, mechanical, and durability properties compared with commercial single-layer AR coatings.

Is there a new LCI for crystalline silicon PV systems?

In late 2020, IEA PVPS released an updated LCI for PV systems that contains updates for crystalline silicon PV technology reflecting the year 2018, while some information, such as the amounts of auxiliary materials, are still based on 2011 .

Are glass-glass modules better than glass-foil modules?

Glass-glass modules also have a longer lifetime and lower annual degradation than modules with a film, which further improves their carbon footprint. In terms of kilowatt hours generated, frameless glass-glass modules produce 22 to 27 percent less CO2 emissions than glass-foil modules.

Why do we need crystalline silicon for photovoltaic (PV) energy conversion?

Crystalline silicon is needed in large and ever-increasing amounts, in particular for photovoltaic (PV) energy conversion. Efficient thin-film absorbers, for example, based on abundant and stable compound semiconductors, were considered to reduce material consumption.

What is a glass-glass module?

Glass-Glass module designs are an old technology that utilises a glass layer on the back of modules in place of traditional polymer backsheets. They were heavy and expensive allowing for the lighter polymer backsheets to gain the majority of the market share at the time.

Related Articles

-

Pvb double glass photovoltaic module project

Pvb double glass photovoltaic module project

-

Mogadishu double glass photovoltaic module price

Mogadishu double glass photovoltaic module price

-

Czech multicrystalline photovoltaic module prices

Czech multicrystalline photovoltaic module prices

-

Jakarta non-standard photovoltaic glass module quality merchants

Jakarta non-standard photovoltaic glass module quality merchants

-

Democratic Republic of Congo double glass photovoltaic module type

Democratic Republic of Congo double glass photovoltaic module type

-

Photovoltaic module glass reflection

Photovoltaic module glass reflection

-

Sucre New Energy Photovoltaic Module Glass

Sucre New Energy Photovoltaic Module Glass

-

Slovakia crystalline silicon photovoltaic module glass

Slovakia crystalline silicon photovoltaic module glass

-

Riyadh Transparent Series Photovoltaic Glass Module Shipments

Riyadh Transparent Series Photovoltaic Glass Module Shipments

-

Mongolia photovoltaic module glass

Mongolia photovoltaic module glass

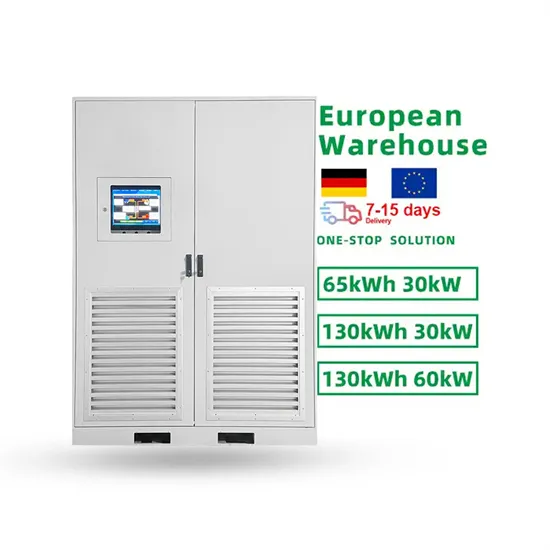

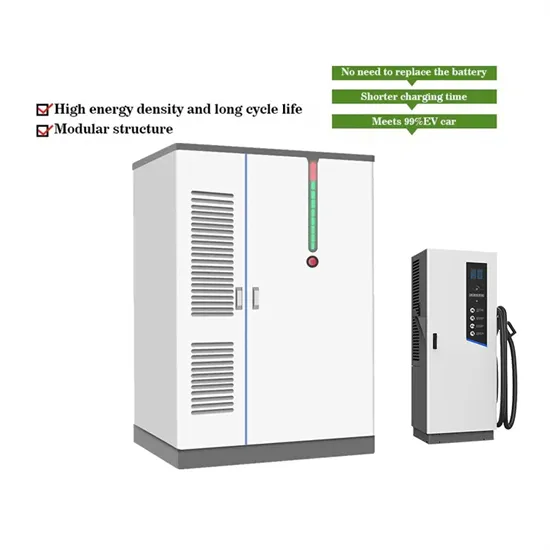

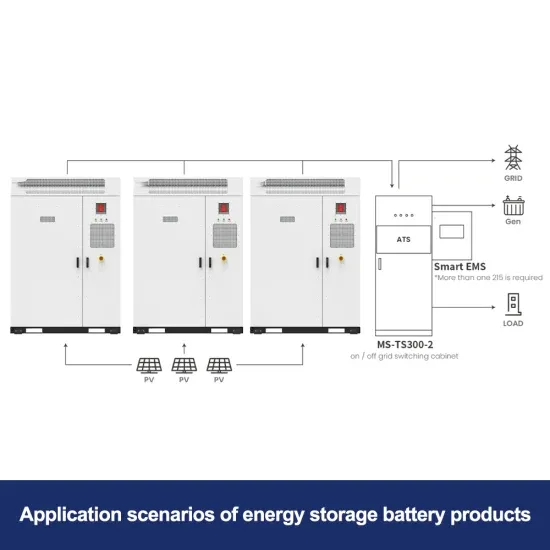

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

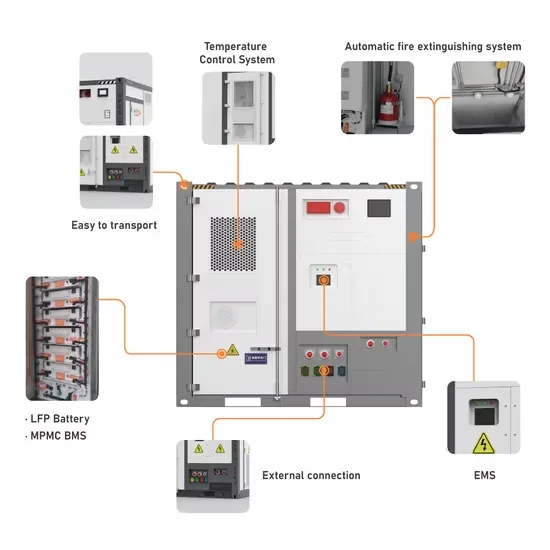

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.