Optimization design and numerical study on water cooling

May 1, 2019 · Download Citation | Optimization design and numerical study on water cooling structure for power lithium battery pack | Lithium-ion batteries are widely used in electric

Get Started

Liquid-Cooled Battery Packs: Boosting EV

Jun 8, 2023 · Engineering Excellence: Creating a Liquid-Cooled Battery Pack for Optimal EVs Performance As lithium battery technology advances in the EVS

Get Started

Battery Cooling Tech Explained: Liquid vs Air

May 9, 2025 · Air Cooling or Liquid Cooling, Which is Suitable? Ultimately, the choice depends on scale and requirements. Air cooling remains viable for low

Get Started

Research on the heat dissipation performances of lithium-ion battery

Nov 8, 2024 · The findings demonstrate that a liquid cooling system with an initial coolant temperature of 15 °C and a flow rate of 2 L/min exhibits superior synergistic performance,

Get Started

Thermal Analysis and Improvements of the

Aug 7, 2019 · The results showed that the maximum temperature of the power battery pack dropped by 1 °C, and the temperature difference was reduced by

Get Started

Optimization design and numerical study on water cooling

Aug 1, 2019 · Lithium-ion batteries are widely used in electric vehicles for their superior performance. The performance of lithium-ion battery can be affected by the issue of overheat.

Get Started

Design of Direct and Indirect Liquid Cooling Systems for

Jul 15, 2025 · ABSTRACT Battery packs for plug-in hybrid electrical vehicle (PHEV) applications can be characterized as high-capacity and high-power packs. For PHEV battery packs, their

Get Started

A novel hybrid cooling system for a Lithium-ion battery pack

Mar 1, 2025 · The study findings indicated that the hybrid cooling model examined can enhance the thermal management of the Lithium-ion battery pack, maintain the maximum battery

Get Started

Improving the air-cooling performance for lithium-ion battery

Feb 25, 2023 · The inlet wind speed and reasonable structure will significantly improve the cooling performance of the air-cooled battery module. Air-cooling battery thermal management system

Get Started

Analyzing the Liquid Cooling of a Li-Ion Battery

Oct 17, 2019 · Lithium-ion (Li-ion) batteries are widely known for their energy efficiency and are becoming the battery of choice for designers of electric

Get Started

Computational fluid dynamic and thermal analysis of Lithium-ion battery

Sep 1, 2016 · In this work, computational fluid dynamic analysis is performed to investigate the air cooling system for a 38,120 cell battery pack. The battery pack contained 24 pieces of 38,120

Get Started

Thermal Management of Lithium-Ion Batteries: A

Mar 14, 2025 · Therefore, a battery thermal management system (BTMS) is essential to ensure the reliable operation and safety of electric vehicles. This study presents a battery thermal

Get Started

Optimization of liquid cooling and heat dissipation system of lithium

Aug 1, 2021 · A stable and efficient cooling and heat dissipation system of lithium battery pack is very important for electric vehicles. The temperature uniformity design of the battery packs has

Get Started

A review of thermal management for Li-ion batteries:

Jul 1, 2021 · Li-ion batteries is mature and well settled in EV industry and can be promising in introducing fast charging technologies via required cooling system integration to the battery pack.

Get Started

Effects of different coolants and cooling strategies on the cooling

Sep 1, 2018 · This paper summarized the development status of the latest power lithium-ion battery liquid cooling system, different types of liquid cooling system were compared, the

Get Started

Immersion cooling innovations and critical hurdles in Li-ion battery

Apr 1, 2025 · The study of typical battery cooling techniques seems insufficient to attain temperature homogeneity in the battery pack during fast-charging applications.

Get Started

Advances in battery thermal management: Current

Aug 1, 2024 · A variety of thermal management techniques are reviewed, including air cooling, liquid cooling, and phase change material (PCM) cooling methods, along with their practical

Get Started

Design and Optimization of Air-Cooled Structure in Lithium-Ion Battery Pack

Mar 19, 2025 · This paper focuses on the thermal management of lithium-ion battery packs. Firstly, a square-shaped lithium iron phosphate/carbon power battery is selected, and a battery

Get Started

Research on the heat dissipation performances of lithium-ion battery

Nov 8, 2024 · Lithium-ion power batteries have become integral to the advancement of new energy vehicles. However, their performance is notably compromised by excessive

Get Started

Thermal management of Li-ion battery pack using potting

Nov 1, 2024 · This paper presents a detailed study on the application of potting material in combination with air cooling for thermal management in a 3s3p NMC 21700 Li-ion battery

Get Started

Numerical Simulations for Lithium-Ion Battery

Feb 10, 2023 · Qian et al. [25] proposed an indirect liquid cooling method based on minichannel liquid cooling plate for a prismatic lithium-ion battery pack and

Get Started

EV Battery Cooling: Key Applications and Impact

5 days ago · Battery thermal management systems leverage passive air cooling and active heat pump technology to maintain optimal battery temperature,

Get Started

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · Choosing the right cooling mechanism for a lithium-ion battery pack for electric vehicles and developing an appropriate cooling control plan to maintain the heat contained

Get Started

Research progress on power battery cooling technology for

Feb 1, 2020 · Proper cooling technology can reduce the negative influence of temperature on battery pack, effectively improve power battery efficiency, improve the safety in use, reduce

Get Started

Heat transfer characteristics of liquid cooling system for lithium

Jan 11, 2024 · To improve the thermal uniformity of power battery packs for electric vehicles, three different cooling water cavities of battery packs are researched in this study: the series one

Get Started

Thermal Management of Lithium-Ion Battery Pack with Liquid Cooling

May 6, 2023 · This study is done for the thermal management of battery cells by using liquid cooling to maintain equal temperature among all the cells in the battery pack. This study starts

Get Started

A review of air-cooling battery thermal management systems for electric

Jul 31, 2021 · Yu et al. [158] developed a three-stack battery pack with the stagger-arranged Lithium-ion battery cells on each stack with two options: natural air cooling and forced air

Get Started

Thermal analysis of lithium-ion battery of electric vehicle

Apr 15, 2024 · This comprehensive study delves deeply into the realm of electric vehicle (EV) battery temperature management, with a central focus on optimizing cooling systems using

Get Started

Comparison of cooling methods for lithium ion

Dec 13, 2023 · At present, the common lithium ion battery pack heat dissipation methods are: air cooling, liquid cooling, phase change material cooling and

Get Started

Related Articles

-

Victoria Power Tools Lithium Battery Pack

Victoria Power Tools Lithium Battery Pack

-

Is it useful to replenish power with a lithium battery pack alone

Is it useful to replenish power with a lithium battery pack alone

-

Zambia 72v power tool lithium battery pack

Zambia 72v power tool lithium battery pack

-

Lithium battery pack power generation

Lithium battery pack power generation

-

Costa Rica Power Lithium Battery Pack

Costa Rica Power Lithium Battery Pack

-

Greek lithium battery pack processing price

Greek lithium battery pack processing price

-

EU outdoor power lithium battery bms system

EU outdoor power lithium battery bms system

-

Lithium battery energy storage high power backup

Lithium battery energy storage high power backup

-

What nickel sheet is used in lithium battery pack

What nickel sheet is used in lithium battery pack

-

How much voltage is used to charge a 7 4v lithium battery pack

How much voltage is used to charge a 7 4v lithium battery pack

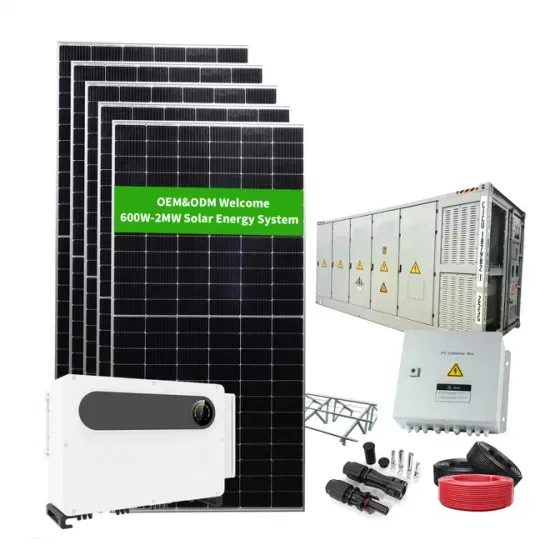

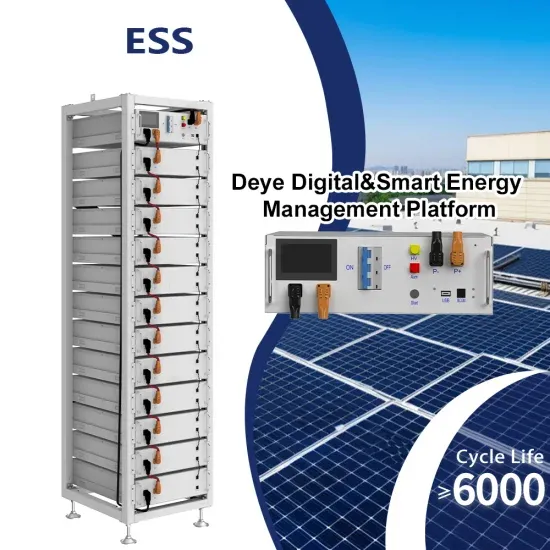

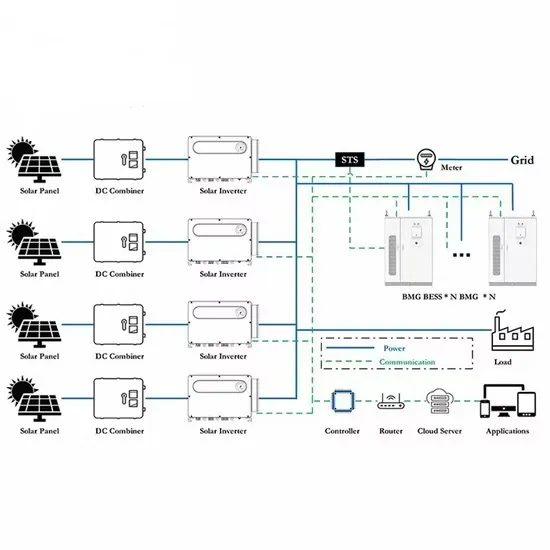

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.