bms生产流程

BMS (Battery Management System) production process is an important aspect of the manufacturing of lithium-ion batteries. BMS is a critical component that ensures the safe

Get Started

Moroni Active Balanced Lithium Battery Project

What is the 16-cell lithium-ion battery active balance reference design? The 16-Cell Lithium-Ion Battery Active Balance Reference Design describes a complete solution for high current

Get Started

Understanding the Role of BMS, EMS, and PCS in Battery

Jan 10, 2025 · Discover the critical roles of BMS, EMS, and PCS in Battery Energy Storage Systems (BESS). Learn how these components ensure safety, efficiency, and reliability in

Get Started

Top 10 Battery Management System

Sep 29, 2023 · With these state-of-the-art testing capabilities, MOKOEnergy ensures the production of top-notch BMS products that comply with the

Get Started

Moroni Lithium Battery Network

The production of lithium-ion battery cells is characterized by a high degree of complexity due to numerous cause-effect relationships between process characteristics.

Get Started

电池管理系统(BMS)及国内部分供应商汇总

Feb 29, 2024 · BMS(battery management system),是电动汽车不可或缺的重要部件,是管理和监控动力电池的中枢,管理、维护、监控电池各个模块,肩

Get Started

Battery Management Systems (BMS): A

Mar 6, 2025 · A Battery Management System (BMS) is essential for ensuring the safe and efficient operation of battery-powered systems. From real-time

Get Started

BMS Production Test System

Mar 25, 2025 · BMS Production Test System The need for comprehensive, scalable, and flexible battery management system (BMS) testing has never been greater. Given the impact on

Get Started

Advances in Battery Manufacturing, Service, and

Oct 3, 2016 · The third part addresses battery management systems (BMS) for control and optimization of battery cells, operations, and hybrid storage systems to ensure overall

Get Started

The Process Behind High-Quality BMS Production

The BMS production process involves several critical steps that require careful consideration and attention to detail. It includes designing the circuit board,

Get Started

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · In the world of lithium-ion batteries, the term "BMS battery" has become increasingly common — especially among manufacturers, engineers, and consumers of

Get Started

Moroni Universal Battery Technical Parameters

What is a battery management system (BMS)? Article 14 mandates that starting from 18 August 2024, battery management systems (BMS) for SBESS, LMT batteries, and electric vehicle

Get Started

Battery production at the Moroni plant

About Battery production at the Moroni plant As the photovoltaic (PV) industry continues to evolve, advancements in Battery production at the Moroni plant have become essential for

Get Started

What is BMS Battery Management System?

Aug 22, 2023 · A BMS battery management system refers to an electronic system responsible for overseeing the operations of a rechargeable battery.

Get Started

A Complete Guide to Lead Acid BMS

Sep 24, 2024 · In today''s world of energy storage, Battery Management Systems (BMS) are essential for ensuring the safety, efficiency, and longevity of

Get Started

List of Top 10 BMS Manufacturers Globally in

Sep 28, 2023 · High-Quality Certified Products: Reliable battery management system suppliers ensure the highest quality and safety standards for BMS

Get Started

Which battery manufacturer is best for Moroni New Energy

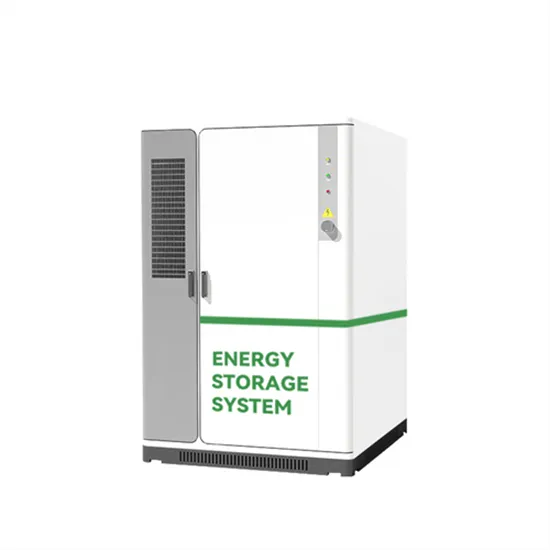

Moroni Energy Storage System Manufacturer AceOn Group are a UK battery pack manufacturer providing a range of battery energy storage systems for the C&I and utility-scale market.

Get Started

LiFePO4 Battery Energy Storage Systems

May 16, 2025 · Additionally, most LiFePO4 battery energy storage systems are equipped with advanced battery management systems (BMS). The BMS monitors and controls various

Get Started

List of Top 10 BMS Manufacturers Globally in

Sep 28, 2023 · There are many factors to consider in selecting an excellent supplier, and accordingly, we have listed the top 10 BMS manufacturers gobally.

Get Started

The Role of Battery Management Systems (BMS)

Apr 8, 2025 · Discover how a Battery Management System (BMS) improves the safety, lifespan, and performance of lithium and AGM batteries in South Africa.

Get Started

Which battery manufacturer is best for Moroni New Energy

Moroni New Energy Battery Technology A global review of Battery Storage: the fastest growing clean energy technology today (Energy Post, 28 May 2024) The IEA report "Batteries and

Get Started

LiFePO4 Battery BMS: 25 Key Parameters for

Discover 25 essential parameters of a LiFePO4 Battery BMS, from smart balancing to Bluetooth connectivity, for safe and efficient battery management

Get Started

Moroni Battery Management System Test

Why is battery management system testing important? In applications ranging from electric vehicles to portable electronic devices,the functionality of a BMS is crucial for ensuring the

Get Started

Powering the Present and Future with Battery

Aug 6, 2025 · Smart and Connected BMS: In order to create a truly smart battery management system, Bosch utilizes a number of IoT solutions. This is

Get Started

电池管理系统BMS知识与功能,一篇入门

Aug 26, 2021 · 1)什么是BMS? BMS全称是Battery Management System, 电池管理系统。它是配合监控储能电池状态的设备,主要就是为了智能化管理及维

Get Started

Industrial Battery Management System (BMS) devices

Oct 13, 2023 · STSW-L9961BMS Firmware package, containing source code and binaries, with standalone firmware driver and application examples (*) * battery voltage, current and

Get Started

moroni battery management systems

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a row x column matrix

Get Started

Battery production, BMS & charging management – our

Whether prototype or series production – we develop battery systems precisely tailored to your requirements. From battery management system development and battery assembly to fully

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Started

电池管理系统(BMS)及国内部分供应商汇总

Feb 29, 2024 · 本文收集了部分国内BMS生产厂商,仅供参考。 随着电动车行业的蓬勃发展, 电池管理系统 (BMS)成为了保障电池性能和安全的关键技术。

Get Started

6 FAQs about [Moroni Battery BMS Production]

Who makes battery management systems (BMS)?

By manufacturing battery management systems (BMS), the company experienced substantial revenue growth in 2021. Furthermore, LG Chem has been the preferred BMS provider for several top automobile manufacturers.

How will BMS technology change the future of battery management?

As the demand for electric vehicles (EVs), energy storage systems (ESS), and renewable energy solutions grows, BMS technology will continue evolving. The integration of AI, IoT, and smart-grid connectivity will shape the next generation of battery management systems, making them more efficient, reliable, and intelligent.

Does mokoenergy have a battery management system?

In 2022, MOKOEnergy’s cumulative energy storage BMS shipments exceeded 10 GWh, with more than 500 projects, ranking second in third-party BMS shipments. MOKOEnergy’s battery management system goes beyond standard battery energy management and thermal regulation by incorporating automatic cell balancing for batteries.

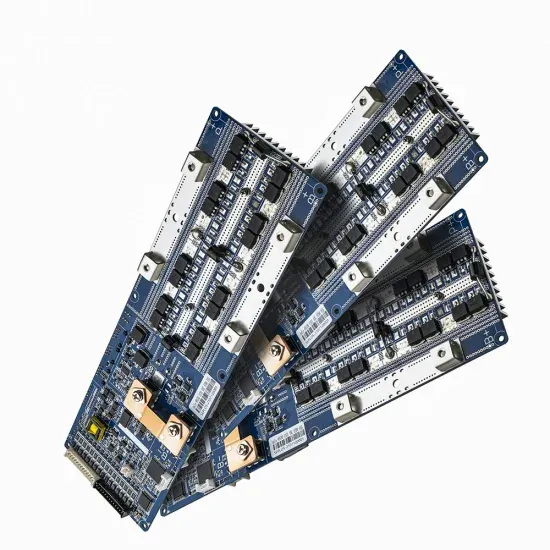

What are the components of a battery management system (BMS)?

A typical BMS consists of: Battery Management Controller (BMC): The brain of the BMS, processing real-time data. Voltage and Current Sensors: Measures cell voltage and current. Temperature Sensors: Monitor heat variations. Balancing Circuit: Ensures uniform charge distribution. Power Supply Unit: Provides energy to the BMS components.

What is a battery management system for Li-ion battery packs?

Let’s take a look at some of the most critical uses of a battery management system for Li-ion battery packs: Cell Monitoring: One of the fundamental uses of a battery management system is that it allows complete monitoring of the voltage, current, temperature, and sometimes other parameters of individual battery cells within a pack.

Which is the best battery management system manufacturer?

MOKOEnergy is one of the best battery management system manufacturers, offering a diverse range of BMS customization options (customizable options: brand, specification, appearance, performance, etc.). Moreover, MOKOEnergy is certified by SGS ISO14001, ISO9001, QC08000, and TS16949.

Related Articles

-

Battery cabinet BMS production line

Battery cabinet BMS production line

-

Moroni battery replacement lithium battery pack

Moroni battery replacement lithium battery pack

-

Moroni DC screen battery cabinet

Moroni DC screen battery cabinet

-

Moroni outdoor power bms price

Moroni outdoor power bms price

-

Beijing lithium battery bms development

Beijing lithium battery bms development

-

BMS battery management system assembly

BMS battery management system assembly

-

San Marino outdoor communication battery cabinet photovoltaic production

San Marino outdoor communication battery cabinet photovoltaic production

-

Port Moresby BMS Battery Management Power System Enterprise

Port Moresby BMS Battery Management Power System Enterprise

-

Haiti Energy Storage Cabinet Battery Production

Haiti Energy Storage Cabinet Battery Production

-

The best lithium battery bms field

The best lithium battery bms field

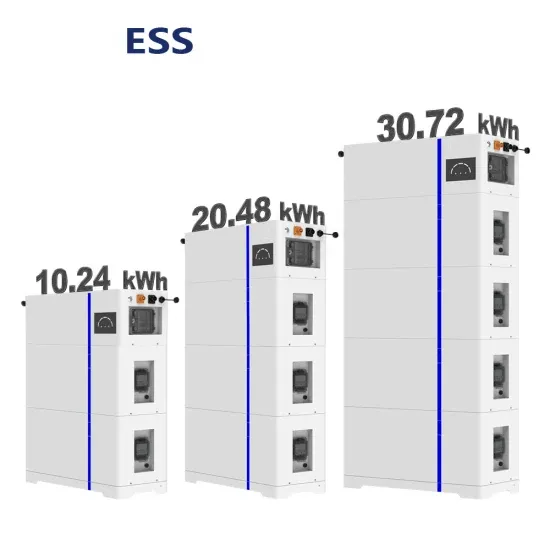

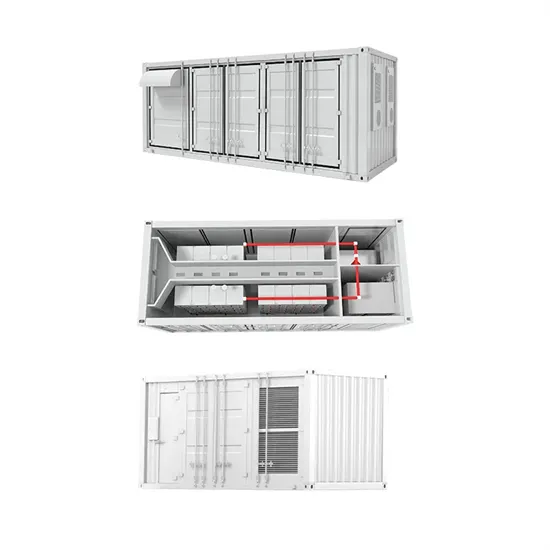

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.