Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Get Started

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Introduction Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV

Get Started

Front glass crack inspection of thin-film solar photovoltaic modules

Ensuring the structural integrity of solar photovoltaic modules is crucial to maintain power production efficiency and fulfill the anticipated product lifespan.

Get Started

Modelling of flexible thin-film modules for building and product

Jul 1, 2018 · In this work we present a simulation of performance of curved thin-film modules for building and product integrated photovoltaic applications. Flexibility of design and possibility of

Get Started

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Get Started

Thin Film Solar Panels

Dec 5, 2022 · In the second generation of crystalline silicon (c-Si) panels, thin film solar cells are created by depositing one or more layers of thin photovoltaic

Get Started

Evaluation and integration of photovoltaic (PV) systems in Albanian

Jun 1, 2024 · This paper aims to investigate and evaluate how Albania''s energy system has included renewable energy sources, particularly photovoltaic (PV) systems. The article aims to

Get Started

A facile photolithography process enabling pinhole-free

Sep 6, 2024 · Release of the alkaline (mainly sodium) impurities from the soda-lime glass (SLG) substrate can compromise scaling-up of thin film photovoltaic (PV) devices deposited at high

Get Started

Top Thin Film Suppliers in Albania

3 days ago · Becoming a multiple wholesale vendor of eCommerce marketplaces, our website lists a wide range of branded thin-film solar cells with a high level of cell efficiency. Check out

Get Started

Albania single glass photovoltaic module panels

Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for thin-film and building

Get Started

Lamination process and encapsulation materials for

May 21, 2024 · Recent developments of thin, 2mm tempered glass have made GG design a more competitive solution, compared with 3 or 4mm GG modules (heavyweight) or standard GBS

Get Started

What are thin-film solar cells? description, and types

Sep 26, 2019 · Thin-film solar cells are the second generation of solar cells. These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate,

Get Started

ZSW: Paving the Way for Thin-film Photovoltaic

Sep 26, 2017 · On top of all this, CIGS thin-film modules have aesthetic advantages that benefit facades. Unlike crystalline silicon PV cells, CIGS thin

Get Started

CdTe Thin Film Solar Module (Solar Glass)

Aug 13, 2025 · LOW TEMPERATURE COEFFICIENT The temperature coefficient of SF CdTe thin film solar moduleis only about -0.21%/℃, as the traditional

Get Started

SPECIALTY THIN GLASS FOR PV MODULES:

Dec 4, 2023 · Glass has long been used for photovoltaic module covers and thin-film module substrates and superstrates. Typically this application uses standard or low-iron soda-lime

Get Started

Thin Films Photovoltaics

Feb 23, 2022 · Thin film photovoltaic-based solar modules produce power at a low cost per watt. They are ideal candidates for large-scale solar farms as well

Get Started

A facile photolithography process enabling pinhole-free thin film

Mar 1, 2023 · Release of the alkaline (mainly sodium) impurities from the soda-lime glass (SLG) substrate can compromise scaling-up of thin film photovoltaic (PV) devices deposited at high

Get Started

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Get Started

Albania Solar Photovoltaic Glass Market (2024-2030)

Market Forecast By Application (Residential, Non-Residential, Utility), By Type (AR Coated Solar PV Glass, Tempered Solar PV Glass, TCO Coated Solar PV Glass, Others), By End-User

Get Started

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros

Thin film photovoltaic modules produce power at low cost per watt. They are ideal for large scale solar farms, as well as Building Integrated Photovoltaic applications (BIPV). They benefit from

Get Started

What are Thin Film Solar Panels? A

Sep 2, 2023 · Definition of Thin Film Solar Panels Simply put, thin film solar panels are quite literally thinner versions of the traditional, bulkier photovoltaic

Get Started

Front glass crack inspection of thin-film solar photovoltaic modules

May 15, 2024 · Thin film solar modules have gained attraction due to their unique advantages over traditional crystalline modules. Thin film technology utilizes various materials, such as

Get Started

Materials selection investigation for thin film photovoltaic module

Jul 15, 2019 · Encapsulation of thin film Photovoltaic (PV) modules is critical from a long term reliability and durability perspective. Currently, the methods and materials used for

Get Started

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Get Started

Thin-Film Solar Panels Explained

Aug 13, 2025 · A brief history of Thin-film solar cells: Through the looking glass In 1961, Adolph Spakowski, head of NASA''s Photovoltaic Fundamentals Section,

Get Started

Growing Panes: Investigating the PV Technology Trends

Jan 20, 2025 · In this article, we identify the concurrent module changes that may be contributing to increased early failure, explain the trends, and discuss their reliability implications. We

Get Started

Flexible design of building integrated thin‐film

May 1, 2022 · The panel-on-demand concept for flexible design of building integrated thin-film photovoltaics is visualized in Figure 1. In the first step, thin

Get Started

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · CIGS and CdTe hold the greatest promise for the future of thin film. Longevity, reliability, consumer confidence and greater investments must be established before thin film

Get Started

Characterization of Performance of Thin-film PV

Apr 15, 2020 · Although thin-film photovoltaic (PV) modules have been in production for decades, the characterization of their performance, both outdoors and under artificial light, remains a

Get Started

Thin-film modules: Benefits and considerations

May 8, 2023 · Thin-film photovoltaic (PV) modules are among the main alternatives to silicon modules in commercial solar energy systems. Thin-film

Get Started

Photovoltaic thin-film modules

Disadvantages of thin-film PV modules As already mentioned, the efficiency of the amorphous solar modules is significantly lower than that of other photovoltaic

Get Started

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the photovoltaic material and other

Get Started

Thin Film Photovoltaics

Jan 1, 2018 · Thin film technology has the answers and potential to eliminate many existing bottlenecks of c-Si photovoltaic (PV) programs experienced at different levels from module

Get Started

Glass Application in Solar Energy Technology

Apr 28, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and

Get Started

6 FAQs about [Albanian thin film photovoltaic module glass]

What are thin-film solar panels?

Thin-film solar panels use a 2 nd generation technology varying from the crystalline silicon (c-Si) modules, which is the most popular technology. Thin-film solar cells (TFSC) are manufactured using a single or multiple layers of PV elements over a surface comprised of a variety of glass, plastic, or metal.

When did thin-film solar panels come out?

In 1980, researchers finally achieved a 10% efficiency, and by 1986 ARCO Solar released the G-4000, the first commercial thin-film solar panel. Thin-film solar panels require less semiconductor material in the manufacturing process than regular crystalline silicon modules, however, they operate fairly similar under the photovoltaic effect.

How are amorphous silicon (a-Si) thin-film solar panels made?

There are two routes to manufacture amorphous silicon (a-Si) thin-film solar panels, by processing glass plates or flexible substrates. Efficiency for a-Si solar cells is currently set at 14.0%. Disregarding the route taken to manufacture amorphous silicon (a-Si) thin-film solar panels, the following steps are part of the process:

What materials are used for thin-film solar technology?

The most commonly used ones for thin-film solar technology are cadmium telluride (CdTe), copper indium gallium selenide (CIGS), amorphous silicon (a-Si), and gallium arsenide (GaAs). The efficiency, weight, and other aspects may vary between materials, but the generation process is the same.

How are CIGS thin-film solar panels made?

Manufacturing for Copper Indium Gallium Selenide (CIGS) thin-film solar panels has improved throughout history. Currently, CIGS thin-film solar cells are manufactured by placing a molybdenum (Mo) electrode layer over the substrate through a sputtering process. The substrate is usually manufactured with polyimide or a metal foil.

How much does a thin-film solar cell cost?

The rated efficiency for GaAs thin-film solar cells is recorded at 29.1%. The cost for these III-V thin-film solar cells rounds going from $70/W to $170/W, but NREL states that the price can be reduced to $0.50/W in the future.

Related Articles

-

Uzbekistan thin film photovoltaic module glass

Uzbekistan thin film photovoltaic module glass

-

Photovoltaic double glass module sun room

Photovoltaic double glass module sun room

-

Sucre New Energy Photovoltaic Module Glass

Sucre New Energy Photovoltaic Module Glass

-

Mongolia photovoltaic module glass

Mongolia photovoltaic module glass

-

Lome multicrystalline photovoltaic module glass

Lome multicrystalline photovoltaic module glass

-

Luxembourg monocrystalline photovoltaic module glass

Luxembourg monocrystalline photovoltaic module glass

-

Photovoltaic module rear glass size

Photovoltaic module rear glass size

-

Mogadishu double glass photovoltaic module price

Mogadishu double glass photovoltaic module price

-

Glass photovoltaic module sales in Kathmandu

Glass photovoltaic module sales in Kathmandu

-

Malaysia single glass photovoltaic module panels

Malaysia single glass photovoltaic module panels

Commercial & Industrial Solar Storage Market Growth

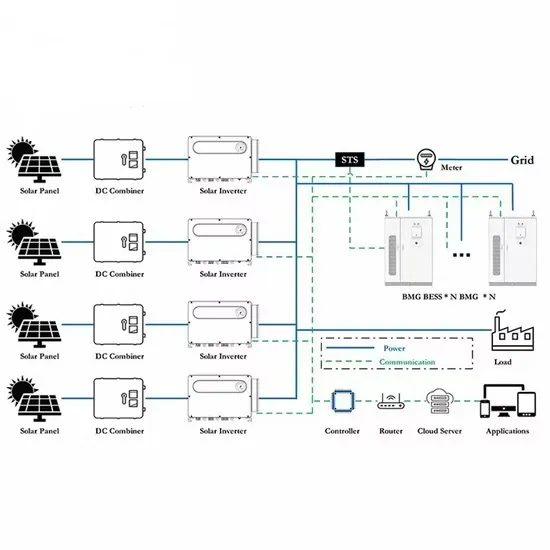

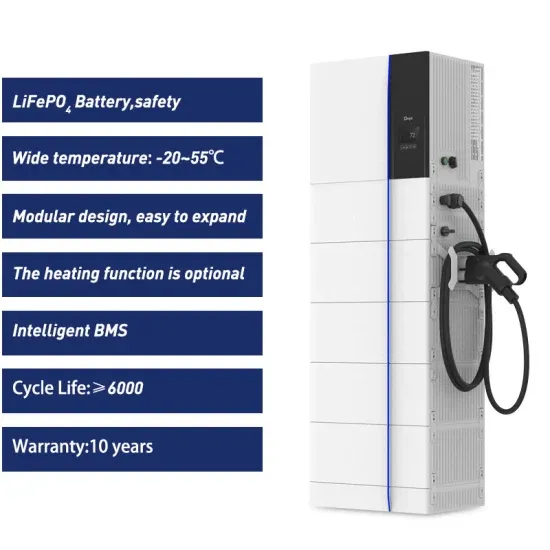

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.