Designing EV Battery Manufacturing Plants: A

Apr 23, 2025 · Discover the essential steps and considerations for designing efficient EV battery manufacturing plants. This guide covers site selection, layout optimization, and sustainable

Get Started

Lithium Batteries: Safety, Handling, and Storage

Nov 14, 2022 · Assembling Battery Packs ETs or Instrument Technicians may occasionally be assembling battery packs or manufacturing battery packs from cells. It is important to follow

Get Started

How To Establish A Battery Pack Manufacturing Factory

Feb 8, 2025 · Building a battery pack manufacturing factory is a strategic endeavor that requires meticulous planning, technical expertise, and a clear understanding of market demands.

Get Started

2018 Title Contents

Dec 20, 2022 · Abstract Changes in requirements to meet battery room compliance can be a challenge. Local Authorities Having Jurisdictions often have varying requirements based on

Get Started

Here are the 4 Top Considerations in Lithium-Ion

Sep 6, 2021 · Here are the 4 Top Considerations in Lithium-Ion Battery Plant Design Building a battery plant requires more than just brick and mortar

Get Started

Battery Pack Manufacturing Process: Step-by-Step Guide

Dec 2, 2024 · The number of batteries and modules integrated into the battery pack can vary significantly based on the battery model and the intended application. This flexibility allows

Get Started

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Get Started

Eve Energy''s 60GWh Super Energy Storage Plant

Dec 13, 2024 · On December 10th, Eve Energy''s 60GWh Super Energy Storage Plant Phase I & Mr. Big has been put into production. This factory is the

Get Started

Tracking the EV battery factory construction

Feb 8, 2025 · In March 2023, Stellantis, a multinational automotive corporation, and Samsung SDI, a leading battery technology company, commenced

Get Started

Types of International Battery Safety Standards

Oct 3, 2023 · Battery safety standards refer to regulations and specifications established to ensure the safe design, manufacturing, and use of batteries.

Get Started

Battery Manufacturing Plant Report 2025: Setup and Cost

The battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

Get Started

Battery Pack Manufacturing Process: Step-by-Step Guide

Dec 2, 2024 · Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Get Started

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · For increasing safety, extending pack service life, and lowering costs, selecting the right cooling method for a lithium-ion (Li-ion) battery pack for electric drive vehicles (EDVs)

Get Started

Fundamentals of Electric Vehicle Battery Pack Design

Dec 24, 2024 · Description This NOS unit is about preparing for the most discussed field of electric vehicles and the emerging trends in battery usage. This NOS unit is about designing

Get Started

Battery Pack Assembly Cleanroom Requirements

Jul 15, 2025 · How can we reduce energy consumption in battery cleanrooms without compromising quality? What materials should be avoided in lithium battery cleanroom

Get Started

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · Segments of the production line The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and

Get Started

Design for Assembly and Disassembly of Battery Packs

Aug 23, 2019 · A key factor for succeeding in installation as well as recycling of battery packs is the ability to modularise the battery pack design to enable high level of configurability needed

Get Started

Battery Pack Manufacturing Process

Mar 15, 2025 · Understanding how battery packs are manufactured is crucial as industries demand higher performance and sustainability. From raw material

Get Started

Complete Guide for Battery Enclosure

May 29, 2024 · Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

Get Started

Battery Plant Design Do''s and Don''ts

Sep 15, 2023 · Battery factories require a new way of thinking about plant design and construction. Manufacturing engineers must pay careful attention to

Get Started

Building the world''s biggest lithium ion battery plant

Jul 28, 2016 · The Gigafactory is being created to manufacturing the volumes of of long-range battery packs required by sustainable vehicle producer, Tesla, for its mass market electric

Get Started

439747_1_En_8_Chapter 175..200

Feb 10, 2018 · According to NASA-Battery Safety Requirements Document (JSC 20,793 Rev C), cell spacing is more critical for pack designs employing battery cells of gravimetric energy

Get Started

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

Get Started

Battery Pack Certifications – Costs, Timelines and Key

All of the costs and the lead times of these tests will vary depending on the battery construction, capacity, pack size, cycle requirements, and where the battery will be certified. In our initial

Get Started

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · Lithium-ion battery pack construction requires systematic engineering methodology across electrical, mechanical, and safety disciplines. The design process demands careful

Get Started

Understanding Lithim Battery Pack Enclosure

May 7, 2025 · Understanding Lithium Battery Pack Enclosure Design for Electric Vehicles and Boats At Bonnen Battery, we specialise in crafting high

Get Started

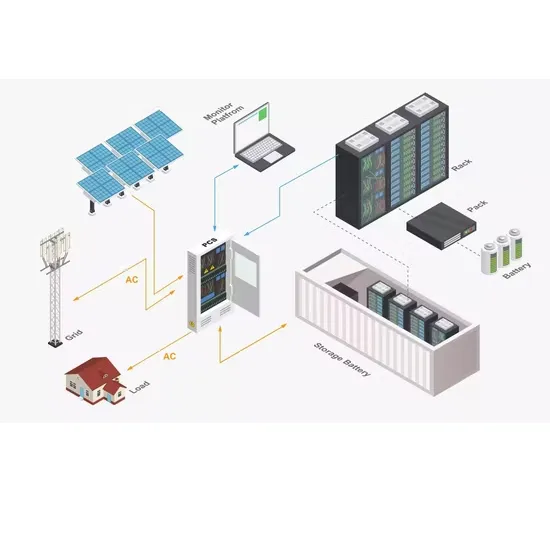

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Get Started

Lithium-Ion Battery Manufacturing Plant: Setup

The lithium-ion battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · The battery pack is enclosed in a structurally optimized casing to withstand external conditions. Efficient electric connections are established

Get Started

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · CMB''s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate

Get Started

How To Establish A Battery Pack Manufacturing Factory

Feb 8, 2025 · Whether you''re targeting electric vehicles (EVs), energy storage systems (ESS), or consumer electronics, this guide outlines critical steps, budget considerations, and

Get Started

Facilities of a lithium-ion battery production plant

Mar 13, 2024 · The extremely low humidity requirements during cell assembly and, particularly, for the electrolyte filling step, are a challenge in lithium-ion battery manufacture.

Get Started

6 FAQs about [Battery PACK factory construction requirements]

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is the set-up of a battery production plant?

This Chapter describes the set-up of a battery production plant. The required manu-facturing environment (clean/dry rooms), media supply, utilities, and building facil-ities are described, using the manufacturing process and equipment as a starting point. The high-level intra-building logistics and the allocation of areas are outlined.

How do you develop a custom battery?

The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support. Developing custom battery solutions requires extensive expertise across electrical, mechanical, and quality engineering.

How many battery cells and modules are required?

The number of cells and modules required varies depending on the specific application model. This initial connection of battery cells sets the stage for the subsequent steps in the manufacturing process. With the connected battery cells in hand, the next step is modularization.

Related Articles

-

Chisinau lithium battery pack factory

Chisinau lithium battery pack factory

-

Kigali PACK Battery Factory

Kigali PACK Battery Factory

-

North America Battery Pack Factory

North America Battery Pack Factory

-

Colombia 24v lithium battery pack factory

Colombia 24v lithium battery pack factory

-

Seychelles pack lithium battery factory

Seychelles pack lithium battery factory

-

Tunisia battery pack factory

Tunisia battery pack factory

-

Huawei Estonia cylindrical battery pack factory

Huawei Estonia cylindrical battery pack factory

-

Vietnam Pack Battery Factory

Vietnam Pack Battery Factory

-

Lithium battery pack factory voltage

Lithium battery pack factory voltage

-

St George Lithium Battery PACK Factory

St George Lithium Battery PACK Factory

Commercial & Industrial Solar Storage Market Growth

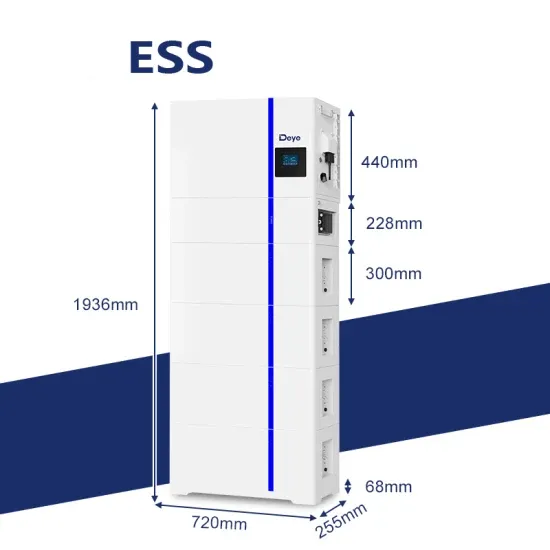

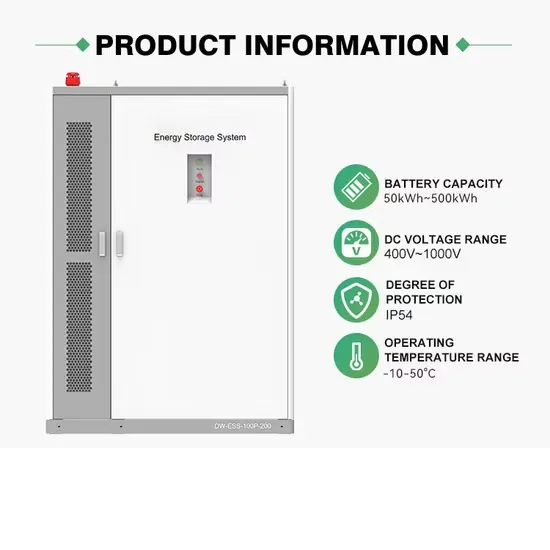

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.