Li-ion Battery Pack: Manufacturing, Characteristics, Advantages

Jan 29, 2024 · This article provides insights into the manufacturing process, characteristics, advantages, usage methods, and key considerations for selecting the right Li-ion battery pack.

Get Started

Advantages of lithium battery PACK factory

May 14, 2024 · Advantages of lithium battery PACK factory automation With the advancement of science and technology, the labor advantage that the

Get Started

Lifepo4 Battery Pack Factory

Manufacturer of high-quality lifepo4 battery packs for a variety of applications, including cars, motorcycles, forklifts, and golf carts. 12V and 24V LiFePO4

Get Started

Exploring Battery Packs: Manufacturing, Advantages, and

As with any electrical device, battery packs have their advantages and disadvantages. Whether considering their chemical composition, power capacity, or storage capabilities, several factors

Get Started

Electric Vehicle Lithium Battery, EV Lithium lon

Sinopoly Battery Limited ("Sinopoly") is an integrated high-tech group which specializes in production, sales and R&D of high-capacity lithium-ion battery

Get Started

Direct recycling of Li-ion batteries from cell to

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

Get Started

The advantages of more elegant circuit design in battery packs

May 13, 2025 · Modern battery packs are often designed with two competing needs in mind. On the one hand, the primary purpose of batteries is to localize power needs. By definition, battery

Get Started

China Battery Pack Assembly Line Manufacturers Suppliers

Aug 13, 2025 · ACEY is one of the most professional battery pack assembly line manufacturers and suppliers in China, specializing in providing high-quality products and services. Please

Get Started

Top 10 LiFePO4 Battery Pack Factory in 2025

May 21, 2024 · Discover the definitive guide to the leading LiFePO4 battery pack manufacturers of 2025. Explore their featuresto make an informed decision.

Get Started

5 Things Battery Pack Manufacturers Must Do

Battery pack manufacturers need to consider proximity to raw material suppliers, labor availability, and logistical ease for shipping and distribution. A well

Get Started

EM3ev-Custom Lithium Battery Pack Solutions

EM3ev offers custom lithium battery packs for e-bikes and energy storage. Known for reliability and long lifespan, contact EM3ev for Solutions

Get Started

EV Battery & Energy Storage Battery

HVPACK is a leading expert in professional solutions for commercial vehicle batteries, machinery batteries, and energy storage systems. Our batteries are

Get Started

Battery Pack Manufacturing Process

Mar 15, 2025 · Understanding how battery packs are manufactured is crucial as industries demand higher performance and sustainability. From raw material

Get Started

Sustainable manufacturing practices for EV battery packs:

Jun 1, 2025 · As an end result, there is a growing want for sustainable production practices that lessen energy consumption, minimize environmental impact, and enhance the recyclability of

Get Started

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · But before this lithium-ion battery manufacturing process, the custom li-ion battery factory should have the advantage of li-ion cell supply chain. We only do business with the

Get Started

18650 Rechargeable Battery Pack: Design,

Jan 11, 2024 · With battery technology growing, 18650 cells in powering various electronic devices and systems play important roles. We will share the

Get Started

Products

EVE is the world''s leading full-scenario lithium battery solution provider, since its establishment in 2001, has always been driven by technological innovation development, business covers

Get Started

Cylindrical Battery Pack Production Line: Advantages Driving

Jul 29, 2025 · Discover the advantages of cylindrical battery pack production lines, including high automation, boosted efficiency, cost reduction, consistent quality, and enhanced safety. Learn

Get Started

Nearly 10 battery companies built factories in Southeast Asia

Sep 12, 2023 · Nearly 10 battery companies built factories in Southeast Asia At present, Chinese domestic power battery companies accelerate the formation of groups to go abroad, with core

Get Started

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · The lithium battery module PACK production line is a production line that combines multiple battery cells into a complete battery module and

Get Started

Comparison of the 12V 4S 18650 Battery Pack with Other Types of Battery

12V 4S 18650 battery pack excels in energy density, compact size, and voltage compatibility, making it especially suitable for scenarios that demand portability and long battery life.

Get Started

How To Establish A Battery Pack Manufacturing Factory

Feb 8, 2025 · Establishing a battery pack factory demands a balance between technical precision and financial prudence. By prioritizing advanced equipment like laser welding machines,

Get Started

How Do Lithium-Ion Battery Packs Work and What Are Their Advantages?

Nov 12, 2024 · Lithium-ion battery packs are essential components in modern technology, powering everything from smartphones to electric vehicles. They operate through the

Get Started

advantages and disadvantages of the lithium-ion battery

2020-01-31 CTECHi 393 Huizhou JB Battery Technology Co., Ltd. is one of the leading manufacturers of customized lithium-ion battery packs in China and is able to design and

Get Started

What do CTP (Cell to Pack) and blade batteries mean, and

Oct 8, 2021 · What do CTP (Cell to Pack) and blade batteries mean, and what are their advantages? Starting from the second half of 2019, the CTP (Cell to Pack) and BYD blade

Get Started

5 Automation Advantages for EV Battery

Feb 6, 2025 · To take advantage of the growth of Electric Vehicles, manufacturers can meet the increase in demand by automating their battery production.

Get Started

What are the advantages and disadvantages of lithium battery pack

The advantages of lithium battery packs have good high temperature function: the peak heat of lithium iron phosphate battery packs can reach 350℃-500℃, and the operating temperature

Get Started

Introduction of lithium ion battery factory and

Jul 29, 2025 · Lithium ion battery factory 16-year professional lithium ion battery factory, 10-year warranty on battery packs, using the best BMS protection

Get Started

Comparison of advantages and disadvantages of soft pack

Lithium batteries can be divided into three packaging forms: cylindrical, square, and soft. Cylindrical and square batteries are packaged in steel and aluminum shells, respectively, while

Get Started

6 FAQs about [Battery PACK Factory Advantages]

What makes a successful battery pack manufacturing process?

Effective cell selection and procurement lay the groundwork for successful battery pack manufacturing, directly impacting the quality and performance of the final product. The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs.

What are the advantages of a high-voltage battery pack?

High-voltage battery packs (200V–800V) for extended range. Fast-charging capabilities to minimize downtime. Thermal management systems to prevent overheating. Compact and lightweight designs for smartphones, laptops, and wearables. Energy-dense lithium-ion cells for long battery life. Fast discharge rates for high-performance gadgets.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

What makes a good battery pack?

Whether you’re a professional or a curious reader, this guide will provide a clear and detailed overview. The foundation of any high-performance battery pack begins with selecting the right battery cells. This critical decision influences the overall performance, lifespan, safety, and cost of the final battery pack.

Why do you need a customized battery pack?

Different industries require customized battery packs tailored to specific voltage, capacity, and form factor requirements. Customization ensures optimal performance, safety, and efficiency for various applications, including electric vehicles (EVs), consumer electronics, and energy storage systems. 1.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

Related Articles

-

Battery PACK factory construction requirements

Battery PACK factory construction requirements

-

Huawei Estonia cylindrical battery pack factory

Huawei Estonia cylindrical battery pack factory

-

Praia regular lithium battery pack factory price

Praia regular lithium battery pack factory price

-

How much does a lithium battery pack factory cost

How much does a lithium battery pack factory cost

-

North America Battery Pack Factory

North America Battery Pack Factory

-

Colombia 24v lithium battery pack factory

Colombia 24v lithium battery pack factory

-

Tunisia battery pack factory

Tunisia battery pack factory

-

48v lithium battery pack factory

48v lithium battery pack factory

-

Macedonia 24v lithium battery pack factory

Macedonia 24v lithium battery pack factory

-

Factory battery pack

Factory battery pack

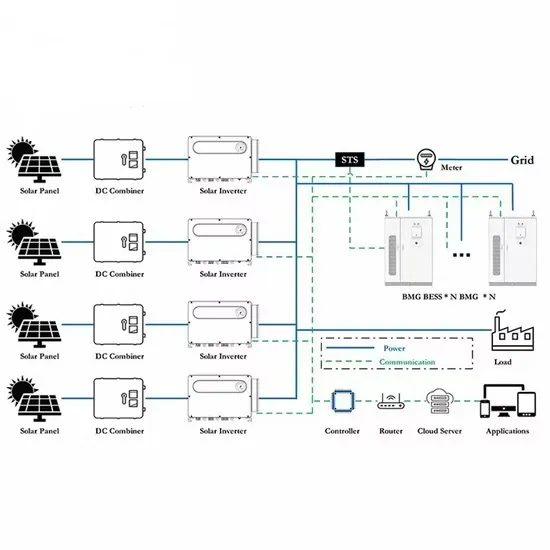

Commercial & Industrial Solar Storage Market Growth

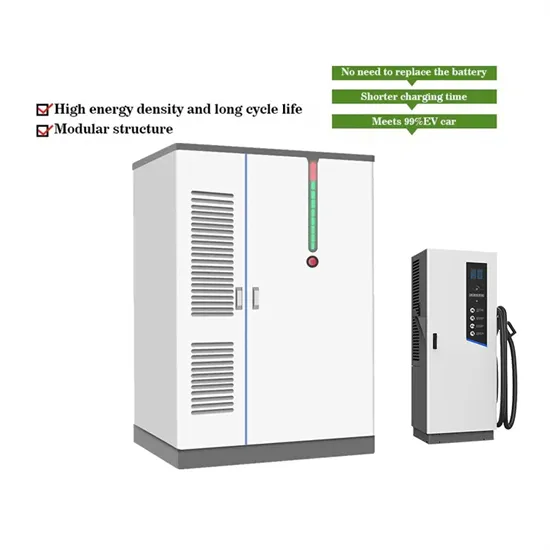

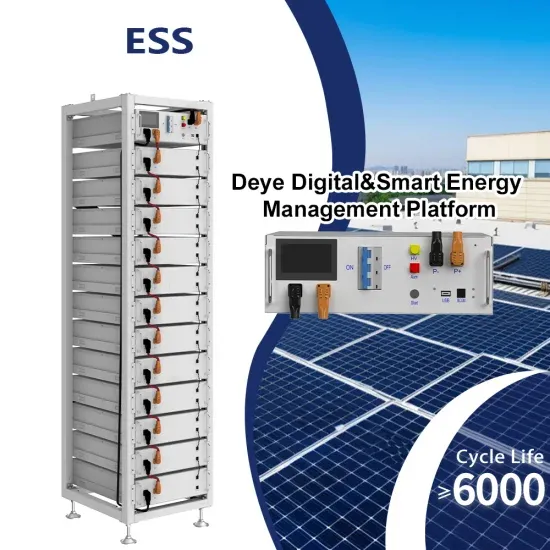

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.