battery cabinet,battery storage cabinet,battery

EverExceed can provide customers with battery Rack, indoor cabinets and outdoor air conditioning cabinets for lithium batteries, which are widely used in

Get Started

Battery Cabinet

Mar 21, 2023 · Lithium Battery Cabinet SmartLi 3.0 Scenario where SmartLi 3.0 lithium battery cabinets are deployed outside the smart module: One integrated UPS can connect to a

Get Started

What''s inside the energy storage cabinet? | NenPower

Jun 4, 2024 · Conversely, lead-acid batteries offer an economically viable option, predominantly in industrial applications. Emerging technologies, such as solid-state batteries, promise

Get Started

lead acid battery cabinet

EverExceed VRLA battery cabinets are very durable, and easy to install. Engineered for use with most type of battery terminal models, these cabinets can fit a wide variety of applications. This

Get Started

Battery Room Design Requirements –

It does not cover maintenance free or computer room type batteries and battery cabinets. Main keywords for this article are Battery Room Design

Get Started

Stationary Lead-Acid Battery Systems

Jan 2, 2017 · SCOPE This guideline applies to all new installations and/or alterations to existing stationary storage battery systems, including flooded lead acid, nickel cadmium, valve

Get Started

Battery Spill Containment

It also requires an approved method, capable of neutralizing a spill from the largest lead-acid battery. In response to these new requirements, Exponential

Get Started

AGM sealed batteries OK inside house?

Jan 18, 2011 · I am planning on buying a couple deep cycle 12V AGM sealed batteries. I want to put the batteries and all the control equipment in a cabinet in my rec. room inside the house

Get Started

System Batteries, Sealed Lead-Acid with Applications

May 3, 2024 · UL, ULC, and External battery cabinet without charger, 4009-9801* Beige FM For batteries up to 33 Ah with locking solid door and battery harness; for close-nippled mounting to

Get Started

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

Get Started

How to Build a Battery Room for Lithium-ion,

Jun 24, 2025 · Battery rooms must be easy to inspect and maintain. Lighting should be bright and resistant to corrosion or acid vapours. Install pull-out

Get Started

AGM are they safe inside

Jul 13, 2021 · I wouldn''t keep lead plate batteries inside. AGMs can potentially last longer than regular ol'' lead plate acid deep cycle batteries.

Get Started

Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Valve-regulated lead-acid (VRLA) batteries can be mounted on racks or in cabinets. The remainder of this paper will address considerations

Get Started

How to calculate battery room hydrogen ventilation

How to calculate hydrogen ventilation requirements for battery rooms.For standby DC power systems or AC UPS systems, battery room ventilation is calculated in accordance to EN 50272

Get Started

What''s Inside Pylontech''s Battery Storage Cabinet?

May 1, 2024 · Why use a battery cabinet? First, it''s helpful to remember that LiFePO4 batteries differ from their traditional lead acid predecessors in terms

Get Started

2018 Title Contents

Dec 20, 2022 · Abstract Changes in requirements to meet battery room compliance can be a challenge. Local Authorities Having Jurisdictions often have varying requirements based on

Get Started

How to Build a Battery Room for Lithium-ion,

Jun 24, 2025 · Build a safe, efficient battery room for lead-acid, lithium-ion & EV batteries. Learn layout, ventilation & charging tips to maximise safety &

Get Started

Battery Cabinets & Enclosures

Exponential Power''s Battery Cabinets & Enclosures provide durable, secure solutions for telecommunications and industrial applications. Designed to protect battery systems, these

Get Started

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · If the VRLA battery is overcharged, venting will occur causing battery dry out and will continue to generate heat inside the battery. Other factors include: high room temperature,

Get Started

Battery cabinets for uninterruptible power supplies

The ENERPOWER battery cabinets are designed to contain hermetic lead acid electric accumulator batteries, and comply with the safety criteria of the current CEI 21-6 / December

Get Started

Replace Your UPS Lead Acid Battery | Mitsubishi

2 days ago · We can help you choose the best lead acid battery replacement for your operations. Learn more about your options, like replacing lead acid

Get Started

Eaton-Battery-Handbook-BAT11LTA.PDF

Apr 20, 2018 · During the charging of a lead-acid battery, hydrogen is normally liberated. In a vented battery, the hydrogen escapes into the atmosphere. In a VRLA battery, the hydrogen

Get Started

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Batteries, the core of the cabinet, store energy in forms such as lithium-ion or lead-acid, noted for their high energy density and cycle life. Chargers ensure that batteries are

Get Started

What''s Inside a Battery? How Does It Work?

Apr 9, 2025 · Explore what''s inside a battery, how it works, and why it matters. Learn about battery parts, safety, and recycling—all in simple, easy-to

Get Started

BATTERY CABINETS CATALOGUE

Jun 4, 2025 · The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries. The construction characteristics of the

Get Started

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

Get Started

VRLA battery cabinets

2 days ago · Function VRLA (Valve Regulated Lead Acid) batteries are lead batteries with a sealed safety valve container for releasing excess gas in the event of internal overpressure.

Get Started

Hydrogen Management in Battery Rooms

2 days ago · Vented Lead Acid (VLA) and vented Ni-Cad (Ni-Cad) batteries are either fully vented or partially recombinant battery types (Figure 1). They are

Get Started

Battery Technology for Data Centers and Network

Jun 20, 2017 · The lead-acid battery is the predominant choice for uninterruptible power supply (UPS) energy storage. Over 10 million UPSs are presently installed utilizing flooded, valve

Get Started

Lead Acid Battery: What''s Inside, Components, Construction,

Jan 1, 2025 · What are the Main Components Inside a Lead Acid Battery? The main components inside a lead-acid battery include lead dioxide, sponge lead, sulfuric acid, separators, and the

Get Started

6 FAQs about [Lead-acid battery cabinet inside]

What are the parts of a lead-acid battery?

The main components inside a lead-acid battery include lead dioxide, sponge lead, sulfuric acid, separators, and the battery casing. These components interact to facilitate energy storage and discharge. Understanding each part’s role helps in appreciating how lead-acid batteries work.

What is a lead acid battery?

It converts chemical energy into electrical energy through electrochemical reactions, providing a stable and reliable power source. The definition aligns with data from the U.S. Department of Energy, which describes lead acid batteries as crucial components in various applications, including automotive and backup power systems.

How do lead-acid batteries work?

Understanding each part’s role helps in appreciating how lead-acid batteries work. Lead dioxide serves as the positive plate in a lead-acid battery. It is a compound made of lead and oxygen. During discharge, lead dioxide reacts with sulfuric acid to generate lead sulfate and release electrical energy.

What is the role of lead dioxide in lead acid batteries?

Lead dioxide plays a critical role in the function of lead acid batteries. It serves as the active material in the positive electrode during the battery’s charging and discharging cycles. The role of lead dioxide in lead acid batteries encompasses various aspects that affect battery performance and environmental consideration.

Are lead acid batteries recyclable?

Lead acid batteries are 97% recyclable, making them an environmentally friendly option when properly processed. Components such as lead, sulfuric acid, and plastic can be reused in new battery production, reducing waste and environmental impact. Lead acid batteries are designed to withstand harsh conditions.

How do lead acid batteries affect the environment?

The use of lead acid batteries affects health and the environment due to the potential release of lead and sulfuric acid. Improper disposal can lead to soil and water contamination, impacting communities. Examples of impacts include the risk of lead poisoning in areas near battery recycling centers and acid spills affecting local ecosystems.

Related Articles

-

Which base stations are covered by the lead-acid battery cabinet

Which base stations are covered by the lead-acid battery cabinet

-

How to deal with lead-acid battery cabinet pulp

How to deal with lead-acid battery cabinet pulp

-

Lead-acid battery cabinet shipping

Lead-acid battery cabinet shipping

-

Lead-acid battery cabinet management

Lead-acid battery cabinet management

-

Niger outdoor lead-acid battery cabinet

Niger outdoor lead-acid battery cabinet

-

Lead-acid battery cabinet safety solution

Lead-acid battery cabinet safety solution

-

How about the lead-acid battery in photovoltaic energy storage cabinet

How about the lead-acid battery in photovoltaic energy storage cabinet

-

Battery cabinet lead-acid battery configuration

Battery cabinet lead-acid battery configuration

-

Praia energy storage battery cabinet manufacturer

Praia energy storage battery cabinet manufacturer

-

Ordinary Battery Cabinet Ranking

Ordinary Battery Cabinet Ranking

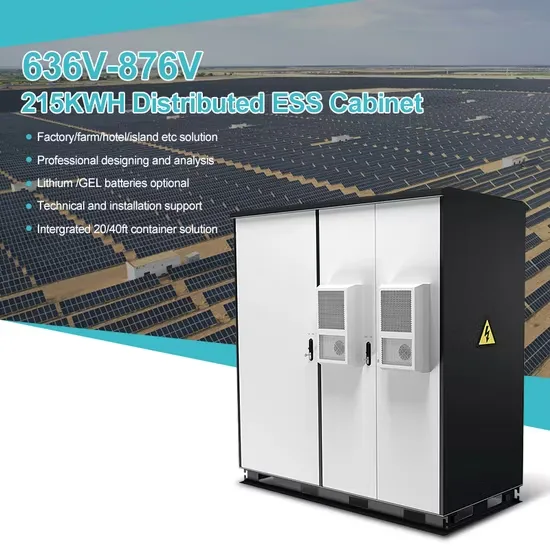

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.