LMG600 Series Application: Traction inverter and its high

However, the conversion process of a traction inverter is associated with various power loss mechanisms, in particular those that arise from the high-frequency (HF) switching processes of

Get Started

Efficiency and Power Loss Distribution in a High-Frequency,

Dec 1, 2023 · The paper presents efficiency and power loss analysis in a high-frequency, seven-level diode-clamped inverter (7LDCB). The inverter is composed of four-level (4L) diode

Get Started

A efficiency optimization and loss balancing method for

Jan 4, 2025 · Three-level active-neutral point-clamped (3L-ANPC) inverters have been widely used in medium and high power photovoltaic systems. But at present, 3L-ANPC inverters still

Get Started

Measurement of Loss in High-Frequency

Feb 6, 2017 · This article introduced a method for measuring and analyzing high-frequency reactor loss, with reference to an actual measurement example.

Get Started

Power Loss Model And Efficiency Analysis of Three

Nov 16, 2019 · The power loss in the conversion system should be minimized as much as possible by selecting proper semiconductor devices of advanced high-voltage, high-operating

Get Started

Experimental study on the influence of high frequency PWM

Nov 1, 2022 · Ref. [18] invented an induction motor efficiency measurement method. This method used a frequency converter to replace the fixed frequency power supply which was used for

Get Started

Analysis of Power Loss and Improved Simulation

A high frequency dual-buck full-bridge inverter for small power renewable energy application is proposed in this paper. A switching frequency of 400 kHz is

Get Started

Analytical Loss Model for Three-Phase 1200V SiC

Mar 8, 2022 · ABSTRACT Next-generation Variable Speed Drive (VSD) systems utilize SiC MOSFETs to achieve both high efficiency through reduced bridge-leg losses and high power

Get Started

A High-Frequency Soft Switched Inverter with a Low-Loss

Oct 24, 2024 · The virtues of Wide Band Gap (WBG) devices and the increasing importance of inverters in the future grid have laid the foundation for high-frequency inverters t

Get Started

A high-accuracy switching loss model of SiC MOSFETs in a

Jun 1, 2021 · Electric traction systems as a kernel part of electric vehicles (EVs) contribute to a substantial power loss, and motor drives in the EV traction system operate with high-frequency

Get Started

Impact of high-frequency harmonics (0–9 kHz) generated by

Nov 1, 2020 · Pulse Width Modulated (PWM) voltage generated by power converters can generate significant high-frequency harmonics at its switching frequency. The switching

Get Started

Understanding inverter frequency – effects and

Oct 1, 2024 · Understanding inverter frequency – effects and adjustments In today''s world, inverters play a vital role in various applications, such as home

Get Started

Active Power Device Selection in High

Oct 8, 2018 · We report the first high-frequency C OSS loss data from silicon carbide (SiC) power MOSFETs, with a range of devices tested from 1 to 35 MHz and up to 800 V. In contrast to

Get Started

The core loss estimation of a single phase inverter transformer

Jul 1, 2021 · The high-frequency high voltage inverter transformer in the circuit topology is of great importance because it provides galvanic isolation. When designing this transformer, the

Get Started

Measuring the power conversion losses in voltage source inverters

Sep 1, 2020 · Although the presented and tested exemplary experimental model is a basic H-bridge inverter with the first modulation scheme [10], [11], the presented idea can be used for

Get Started

High-Frequency Transformerless Grid-Connected

Jul 14, 2022 · Issues Abstract By reviewing the developing history of DC-DC converters in terms of power density, it shows that the power density of transformerless inverters needs increasing

Get Started

Power loss reduction of three-phase inverter in electric

Dec 1, 2024 · The main requirements for EV include high efficiency for improved vehicle mileage and high reliability of its components. For power electronics, the two requirements can be

Get Started

(PDF) Calculation of power losses in a frequency inverter

Sep 1, 2024 · This study''s main goal is to make a new simulation model of the power losses calculation block for frequency converter power switches that can correctly figure out the

Get Started

Investigation of Inverter Motor Loss Using the Power

This means that all high-frequency components of the fundamental wave are lost as useless energy (in the form of heat, sound, and vibration). As a result, engineers developing high

Get Started

Switching loss analysis of IGBT and MOSFET in single phase PWM inverter

Jan 4, 2022 · Simulated results shows that IGBT has low switching loss than MOSFET. 1.3 Paper organisation The following are the discussion on Power loss of inverter switches, Inverter

Get Started

Analysis of Power Loss and Improved Simulation Method

Aug 14, 2017 · A systematic way for calculating the losses of high frequency inverter is presented, and the losses of the components are thoroughly analyzed. The turn-on and turn-off

Get Started

Research on the Application of the High-Power SiC&Si

Dec 3, 2024 · This paper primarily discusses the hybrid application technology of high-voltage SiC MOSFETs and IGBTs in high-power three-level, three-phase inverters. It thoroughly utilizes

Get Started

Investigation of Inverter Motor Loss Using the Power

By observing high-frequency power values that don''t help drive the motor and the associated frequency distribution in real time, it''s possible to develop an intuitive understanding of how

Get Started

Motor Drive Efficiency and Loss at High

Oct 22, 2024 · When comparing the two systems, the coreless motor system exhibited a higher effective power factor, leading to greater inverter efficiency.

Get Started

Adaptive switching frequency PWM method of SiC inverters

Dec 11, 2024 · Electromagnetic interference (EMI) noise resulting from the high-frequency harmonics in voltage source inverters (VSIs) poses a significant challenge in power electronics

Get Started

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · (3) efficiency, and (4) power density. Conventional approach to inverter design is typically based on the architecture illustrated in Fig. 29.1a. A problematic feature of such an

Get Started

A High-Frequency Soft Switched Inverter with a Low-Loss

Oct 24, 2024 · The virtues of Wide Band Gap (WBG) devices and the increasing importance of inverters in the future grid have laid the foundation for high-frequency inverters to emerge as

Get Started

(PDF) Design of High-Frequency, High-Power

Jan 1, 2023 · Design of High-Frequency, High-Power Class $Phi_ {2}$ Inverter Through On-Resistance and Output Capacitance Loss Reduction in 650 V

Get Started

Review of very high frequency power converters

Jul 1, 2020 · Under such high operating frequency conditions, the value and volume of passive components can be greatly reduced, and the power density

Get Started

The Loss Analysis and Efficiency Optimization of Power Inverter

Dec 15, 2020 · Based on this situation, an adaptive discontinuous pulsewidth modulation (ADPWM) is proposed to optimize the power inverter efficiency under the high switching

Get Started

High-Frequency Transformerless Grid-Connected Inverters

Jul 15, 2022 · By reviewing the developing history of DC-DC converters in terms of power density, it shows that the power density of transformerless inverters needs increasing the switching

Get Started

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · ABSTRACT The High-Frequency Inverter is mainly used today in uninterruptible power supply systems, AC motor drives, induction heating and renewable energy source

Get Started

Efficiency and Power Loss Distribution in a High

Dec 1, 2023 · The paper presents efficiency and power loss analysis in a high-frequency, seven-level diode-clamped inverter (7LDCB). The inverter is

Get Started

High-Frequency Transformer Loss Measurement and Modeling: A DC Loss

Dec 18, 2024 · High-frequency transformer is a key component in power electronic converters, yet accurately modeling their losses remains a big challenge. This article introduces a novel direct

Get Started

Review of very high frequency power converters and related technologies

Mar 24, 2020 · Under such high operating frequency conditions, the value and volume of passive components can be greatly reduced, and the power density can be improved. However, many

Get Started

Loss Calculation in a Three-Phase 3-Level

This example shows how to compute switching losses in a three-phase 3-level inverter, combining Specialized Power Systems and Simscape™ blocks.

Get Started

6 FAQs about [High frequency inverter power loss]

Why do power inverters lose power if switching frequency increases?

It is demonstrated that the power losses of power inverter are linearly increased with the rise of switching frequency, which is mainly caused by the switching losses of mosfet chips increment.

Does VSF-hpwm reduce traction inverter power loss?

For this reason, the benefit of the VSF-HPWM on the total power loss of a traction inverter is demonstrated through a comparison with the SVPWM over wide speed and torque range. Furthermore, a method of adjusting the location of the clamping period is illustrated. The rest of this paper is organized as follows.

What is the nominal switching frequency of the inverter?

The nominal switching frequency of the inverter is 10 KHz. The rest of information, such as the switching energy losses, collector-emitter voltage drop, and thermal parameters, which are necessary to calculate the power losses can be found in the datasheet. Fig. 10. Drivetrain configuration with the control scheme for each converter stage. Table 3.

Does dpwm affect switching loss saving in variable power factor?

However, for variable power factor such as in traction applications, the method can't maintain the same switching loss saving because it depends on DPWM with fixed location of the clamping period that is not always aligned with the peak duration of the motor currents.The aim of this study is to address these two issues.

Which traction inverter is best for EV traction?

However, as the power factor slightly changes, the switching loss reduction capability reduces drastically making it less attractive for EV traction inverter since the power factor angle of the traction motor is expected to change frequently. Finally, the GPWM and VSF1-SVPWM offer the best compromise between the THD and loss reduction.

What is the voltage and current rating of an inverter module?

The module has voltage and current rating of 650 V and 400 A, respectively. The nominal switching frequency of the inverter is 10 KHz. The rest of information, such as the switching energy losses, collector-emitter voltage drop, and thermal parameters, which are necessary to calculate the power losses can be found in the datasheet. Fig. 10.

Related Articles

-

High Frequency Inverter Power Supply Company

High Frequency Inverter Power Supply Company

-

High frequency power supply and industrial frequency inverter

High frequency power supply and industrial frequency inverter

-

Industrial frequency and high frequency inverter for RV

Industrial frequency and high frequency inverter for RV

-

High frequency inverter life

High frequency inverter life

-

Buy a high power inverter

Buy a high power inverter

-

High voltage power station inverter

High voltage power station inverter

-

Belgian high frequency inverter price

Belgian high frequency inverter price

-

Poland high frequency uninterruptible power supply

Poland high frequency uninterruptible power supply

-

Brazzaville High Frequency Uninterruptible Power Supply

Brazzaville High Frequency Uninterruptible Power Supply

-

Asia 5kw photovoltaic inverter can be high power

Asia 5kw photovoltaic inverter can be high power

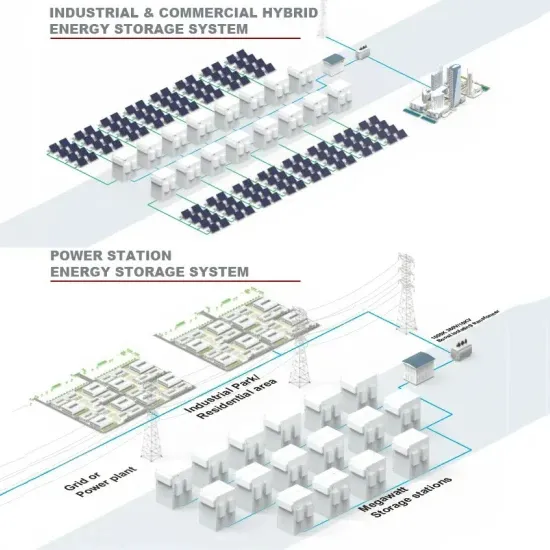

Commercial & Industrial Solar Storage Market Growth

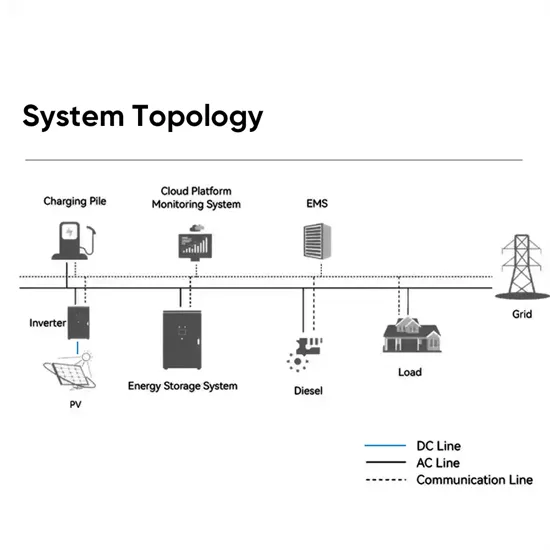

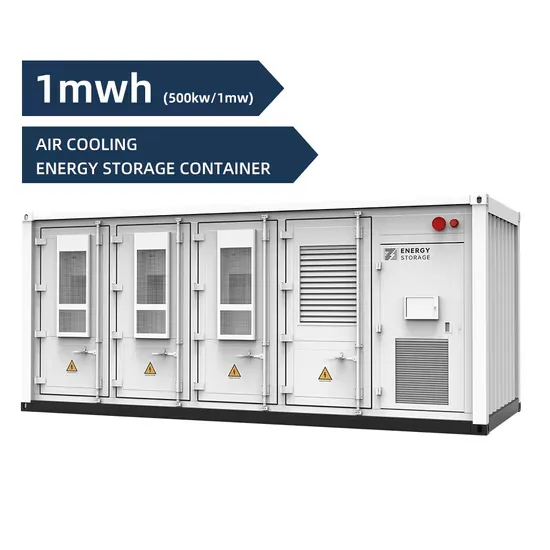

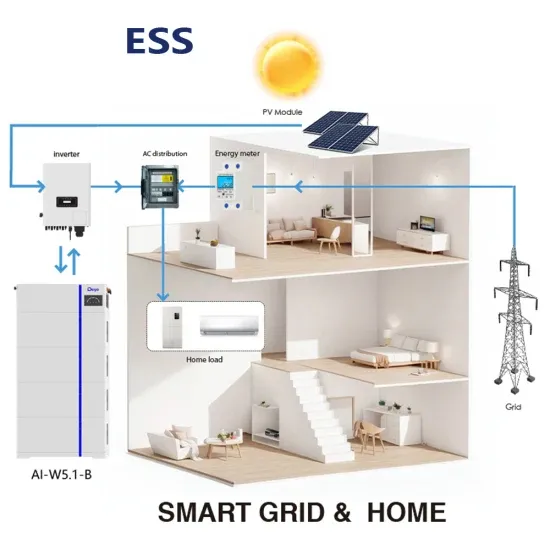

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

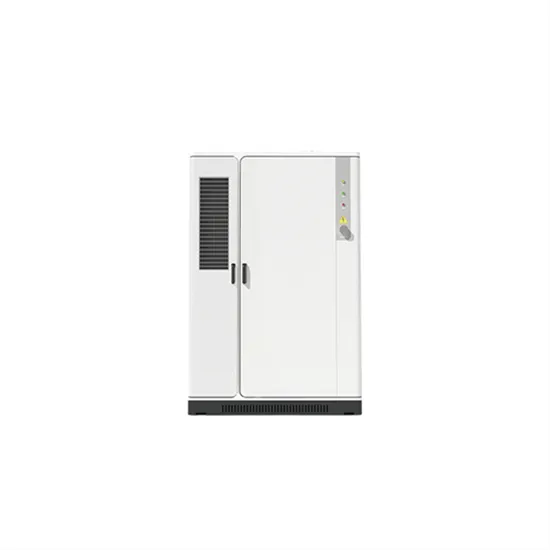

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.