High frequency versus low inverters

Nov 18, 2019 · I have experience with only one of each, but based on that one experience, a low-frequency inverter can have a significantly higher if for draw and can put out much more heat

Get Started

Power Inverter vs. Frequency Inverter

Jan 20, 2021 · The adapter converts the AC voltage of the mains power grid into a stable 12V DC output, while the inverter converts the 12V DC voltage output

Get Started

Inverter Generators: What You Need To Know.

Sep 18, 2016 · Inverter generators convert the high frequency, three phase AC into DC current via a solid state rectifier, and from there the electricity goes

Get Started

A Complete Guide to Inverters/Variable

Jan 1, 2025 · There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical

Get Started

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · Because they generally have less MOSFET''s getting switching at high frequency they have a bit lower idle current. Many inverters have a automatic standby mode. They

Get Started

Inverters High or Low Frequency

Apr 15, 2020 · Not enough to fix what is wrong with modified sine wave inverters, but some. Pretty much all modern inverters are high frequency as in they use high frequency PWM modulation

Get Started

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · The frequency inverter is a power control equipment that applies frequency conversion technology and microelectronics technology to control

Get Started

Power Frequency Inverter vs. High Frequency

May 15, 2024 · High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through

Get Started

Adapt high-frequency inverter with addition of transformer?

Jan 28, 2024 · Yes, an autotransformer can help improve the output of a high-frequency inverter when dealing with inductive loads by mitigating the voltage spikes and current surges caused

Get Started

Technical comparison between Low Frequency

Aug 19, 2025 · What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output

Get Started

What is a High-Frequency Power Inverter?

2 days ago · Introduction A power inverter converts DC power into AC power for operating AC loads and equipment. High-frequency power inverters utilize

Get Started

How to Distinguish High Frequency Inverter and Low Frequency Inverter

Apr 11, 2024 · Low frequency inverters produce less electromagnetic interference, but can only produce lower AC power frequencies, while high frequency inverters can produce higher

Get Started

Power Inverters: The Need-to-Know Essentials

Nov 29, 2022 · Inverters are also used for induction heating. AC mains power is first rectified to DC power, and then the inverter converts it to high frequency AC power used for induction

Get Started

High-Frequency Inverter: How They Work and

4 days ago · A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency,

Get Started

How do inverters convert DC electricity to AC?

Mar 6, 2025 · This is a step-up transformer with more windings in the secondary (yellow zig-zag, right-hand side) than the primary, so it boosts a small AC

Get Started

What are Low Frequency Toroidal Inverters?

Apr 6, 2022 · So here I heard some inverters that are "low frequency toroidal inverters". 1. What are they? Example? 2. What is their advantage vs regular

Get Started

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

Get Started

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Jul 25, 2025 · High-frequency inverters represent a more modern approach, engineered to overcome the size and weight limitations of their line-frequency counterparts. The topology is

Get Started

Which is Better Low Frequency or High

4 days ago · Introduction Inverters convert DC power into AC power to operate AC equipment and devices. They utilize power electronic switching at different

Get Started

Frequency Inverter | inverter

0.75kW single phase output frequency inverter for sale, 1-phase input to 0~input voltage 1-phase output at 220V/230V/240V. Rated current 7A, input voltage single phase AC 220 ± 15%, and

Get Started

Understanding High-Frequency Inverters

Aug 20, 2025 · Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression.

Get Started

Inverter Current Calculator, Formula, Inverter Calculation

6 days ago · Inverter Current Formula: Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the

Get Started

Introduction to Grid Forming Inverters

Jun 18, 2024 · Why do we need Grid-forming (GFM) Inverters in the Bulk Power System? There is a rapid increase in the amount of inverter-based resources (IBRs) on the grid from Solar PV,

Get Started

Understanding the Difference Between Low Frequency and

2 days ago · High-frequency power inverters utilize high-speed switching at frequencies significantly higher than the standard 50/60 Hz grid frequency. This article provides an

Get Started

Inverter Low Frequency vs High Frequency | How Do I

Mar 31, 2024 · There are two main types of inverters: low-frequency inverters and high-frequency inverters. Low-frequency inverters operate at a frequency of 50 or 60 Hz, which is the same

Get Started

High frequency vs low frequency pure sine wave

Aug 16, 2016 · By definition, Low frequency power inverters got the name of "low frequency" because they use high speed power transistors to invert the DC

Get Started

Understanding inverter frequency – effects and

Oct 1, 2024 · In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per

Get Started

6.4. Inverters: principle of operation and

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the

Get Started

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an

Get Started

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · The output frequency of a high-frequency inverter is much higher than the power frequency, usually between a few kilohertz and ten kilohertz. With the use of high-frequency

Get Started

6 FAQs about [How much does a high frequency inverter output]

What is the output frequency of a high-frequency inverter?

The output frequency of the high-frequency inverter is much higher than the power frequency, usually between a few kilohertz and tens of kilohertz.

What are the advantages and disadvantages of high frequency inverters?

Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression. Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel.

Are high-frequency inverters a good choice?

Due to the use of high-frequency switching technology, high-frequency inverters have the advantages of small size, lightweight, and high efficiency, but they also have the problem of relatively poor output waveform quality.

How does a high frequency inverter work?

The inverter bridge contains power switches like IGBTs or MOSFETs. The switches turn on and off at high speed to generate high-frequency pulses. An LC filter smoothens the pulses into sinewave AC output. The output frequency depends on how fast the switches cycle on and off. Common high-frequency inverter circuit configurations include:

What is the range of a high frequency inverter?

High-frequency inverters operate from around 10 kHz up to 1 MHz range, far higher than 50/60 Hz line frequencies. RF inverters can reach up to 30 MHz range. What are some common semiconductor devices used in high-frequency inverters?

What are common high-frequency inverter circuit configurations?

Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs. Filter components – Smaller inductors and capacitors possible at high frequencies. Balance size versus performance.

Related Articles

-

How many k is the best for high frequency inverter potentiometer

How many k is the best for high frequency inverter potentiometer

-

High frequency inverter output efficiency

High frequency inverter output efficiency

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Iraq high frequency inverter device manufacturer

Iraq high frequency inverter device manufacturer

-

Photovoltaic high frequency parallel inverter

Photovoltaic high frequency parallel inverter

-

6000W high frequency inverter

6000W high frequency inverter

-

Pure sine wave output power frequency inverter

Pure sine wave output power frequency inverter

-

High Frequency Inverter Power Supply Company

High Frequency Inverter Power Supply Company

-

High frequency inverter front stage module

High frequency inverter front stage module

-

Low frequency inverter output power difference

Low frequency inverter output power difference

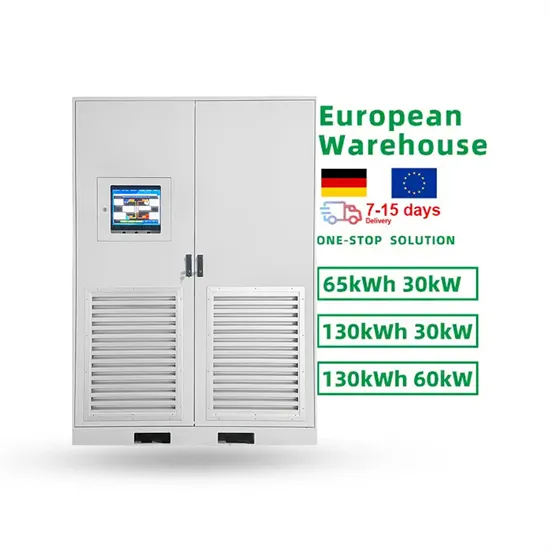

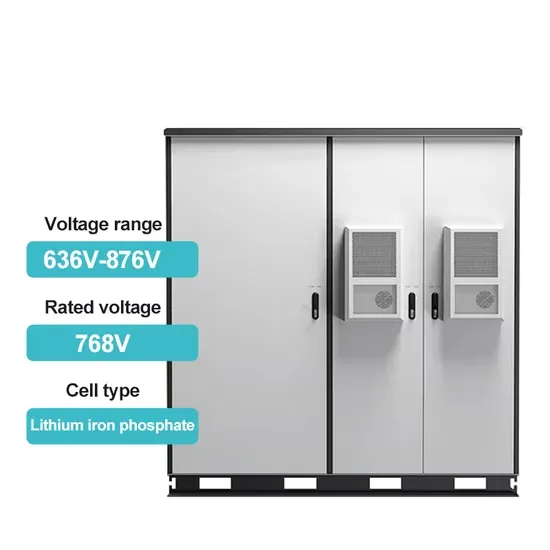

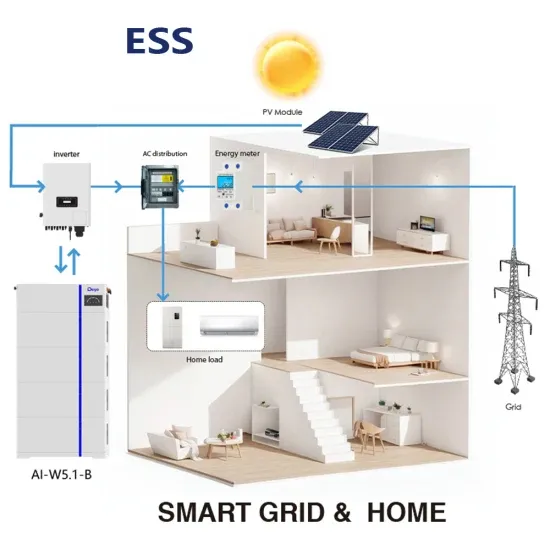

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.