The 3 Most Common Faults on Inverters and how to Fix Them

6 days ago · Once you have identified the problem, you can begin troubleshooting it. Here are some steps to follow: Check the input voltage. The input voltage to

Get Started

What is the optimal AC output voltage for

Oct 4, 2022 · And if the grid voltage is too low or too high, it disconnects. It then monitors the incoming voltage, and if it stabilises within the acceptable range,

Get Started

Background information about grid incidents

If the permissible thresholds for the grid voltage or grid frequency are overshot, the inverter must detect this in accordance with the VDEW guideline requirements and interrupt its feed-in

Get Started

10 common inverter failure and the solutions –

Nov 15, 2023 · When the string output voltage is lower than the minimum input voltage of the inverter, there is no display on the inverter screen. To make

Get Started

Growatt inverter error codes + troubleshooting

Feb 26, 2024 · Growatt inverters are widely used in solar energy systems in order to help convert the direct current (DC) from solar panels into the alternating

Get Started

Inverter Voltage Drop Issue – How to Solve

Dec 21, 2021 · Whenever PWM is employed in an inverter for enabling a sine wave output, inverter voltage drop becomes a major issue, especially if the parameters are not calculated

Get Started

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

Get Started

GROWATT SPF-3500ES TROUBLESHOOTING

If lead acid battery, please test the real battery voltage via multimeter. Too low battery voltage will cause this. 3. If lithium-ion battery, confirm if battery brand

Get Started

7. Trouble Shooting Table

Jan 6, 2025 · 7. Trouble Shooting Table Proceed as follows for quick detection of common faults. DC loads must be disconnected from the batteries and the AC loads must be disconnected

Get Started

Inverter too high output voltage than normal, problem?

Mar 14, 2023 · Hi, One of the inverter of my school generating peak AC voltage of around 280V. My country''s standard mains voltage is around 220 to 230V AC. I have noticed that some cell

Get Started

Troubleshooting for 10-20kUE Three-Phase Inverter

Aug 30, 2022 · If there are several inverters in parallel, and the inverter shows "AC V Outrange" after the inverter feed to grid working for a while, perhaps the grid impedance is too high,

Get Started

Inveter AC output voltage too high?

6 days ago · Inveter AC output voltage too high? jimmyaz Registered Users Posts: 114 August 2016 #1 Guys, Something is wrong... HELP. My component: 24v battery bank 2500W 120V

Get Started

Frequency inverter parameters setting

Sep 5, 2018 · It is used to compensate the inconsistencies between the external setting signal voltage and the frequency inverter internal voltage (+10v); at the same time it''s convenient for

Get Started

Troubleshooting Power Inverter Issues – Online

Jul 20, 2025 · By spotting issues like an inverter not starting or having output voltage problems, you can fix them. This ensures you have power when you

Get Started

Common Frequency Inverter Fault Diagnosis and

Dec 7, 2023 · Reset the parameters and start the frequency inverter without connecting it to a motor. Test the voltage output of U, V, and W phases. If

Get Started

10 common inverter failure and the solutions –

Nov 15, 2023 · In addition to off-grid inverters like TYCORUN 2000w pure sine wave inverter or 3000w inverter, grid-connected inverters also have some

Get Started

These 32 Common Inverter Faults, Have You

3 days ago · Major faults include external faults, transformer overheating, cabinet overheating, unit faults, inverter overcurrent, high voltage power loss, etc. For

Get Started

Difference Between High and Low Frequency Inverter

Apr 30, 2025 · Low-frequency inverters can only invert the low-voltage DC of the battery into low-voltage AC (low-voltage inversion, so it can only be low-frequency inversion), and then boost it

Get Started

Power Inverter Troubleshooting – Common

Sep 29, 2024 · Understanding Your Power Inverter Before diving into troubleshooting, it''s important to understand the basics of how a power

Get Started

The bus voltage of photovoltaic inverter is too high

In standalone and grid-connected PV structures,DC-Bus capacitor is the extremely important passive component. Harmonics and power factor reductionoccur in single-phase PV inverters

Get Started

How to Troubleshoot AC Overvoltage of Solar

Feb 9, 2021 · Finally, if it is confirmed that the AC wire output terminal voltage is normal but the inverter AC voltage failure alarm still exists, the alarm may be

Get Started

Inverter Common Faults Solutions

Jan 21, 2025 · The main reasons are: acceleration time is set too short, current upper limit is set too small, torque compensation (V/F) is set too high. 2.

Get Started

Three Common Faults in PV Inverters and Their

Abnormal Input Voltage 1. Fault Manifestation: The inverter fails to start or suddenly stops during operation, displaying error codes for "input voltage too

Get Started

Three Common Faults in PV Inverters and Their

PV Module Issues: Shadowing, excessive dust accumulation, or damaged cells in the modules can lead to unstable or abnormally low output voltage.Loose or

Get Started

High Voltage Inverter Design

The main circuit includes an inverter DC power supply, IGBT bridge inverter, protection circuits, high frequency high voltage transformers, high frequency

Get Started

High Frequency Inverter vs Low Frequency

Aug 18, 2025 · Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

Get Started

Troubleshooting Inverter Problems: A Step-by-Step Guide

Nov 25, 2023 · Check the Battery: Ensure that the battery is fully charged. If the battery voltage is too low, the inverter may not turn on. Use a multimeter to measure the voltage. If it''s below the

Get Started

Frequency Inverter Troubleshooting

Jun 23, 2023 · Loose power connections can result in overvoltage and overcurrent conditions, blown fuses, and frequency inverter damage. Loose

Get Started

6 FAQs about [The inverter output high voltage frequency is too low]

What are the most common faults on inverters?

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage Overvoltage This is caused by a high intermediate circuit DC voltage. This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage.

How to troubleshoot an inverter?

Once you have identified the problem, you can begin troubleshooting it. Here are some steps to follow: Check the input voltage. The input voltage to the inverter should be within the specified range. If the input voltage is too low or too high, the inverter may not function properly. Check the output voltage and frequency.

What causes a DC inverter to overvoltage?

This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage. There are other causes of DC overvoltage, however. POSSIBLE FIXES: Turn the overvoltage controller is on. Check supply voltage for constant or transient high voltage. Increase deceleration time.

What happens if V/F voltage is increased too much?

Reason: If the V/F voltage is increased too much, the inverter output frequency is already relatively high, and the motor speed is still relatively low (that is, the change in motor speed lags behind the change in inverter frequency), it will cause a stall fault, resulting in an inverter overcurrent fault.

What should I do if my inverter voltage is too high?

Check if the input high voltage power supply exceeds the allowed maximum value (if the supply voltage is too high, adjust the transformer tap to 105%).If overvoltage occurs during deceleration, appropriately increase the inverter’s deceleration time setting.

Why is my inverter screen not working?

Reason 3: The DC input voltage is too low. When the string output voltage is lower than the minimum input voltage of the inverter, there is no display on the inverter screen. To make sure, you can use a multimeter to measure the output voltage of the photovoltaic string to see whether the voltage reaches the minimum input voltage of the inverter.

Related Articles

-

Low frequency inverter output voltage

Low frequency inverter output voltage

-

Low frequency inverter plus high voltage

Low frequency inverter plus high voltage

-

Low frequency inverter output power difference

Low frequency inverter output power difference

-

Inverter high frequency and low frequency

Inverter high frequency and low frequency

-

Inverter voltage high and low

Inverter voltage high and low

-

Inverter from high frequency to low frequency

Inverter from high frequency to low frequency

-

Inverter input voltage is too high or too low

Inverter input voltage is too high or too low

-

High Voltage Inverter vs Low Voltage Inverter

High Voltage Inverter vs Low Voltage Inverter

-

The output voltage of an inverter worth tens of dollars

The output voltage of an inverter worth tens of dollars

-

Uzbekistan high voltage inverter

Uzbekistan high voltage inverter

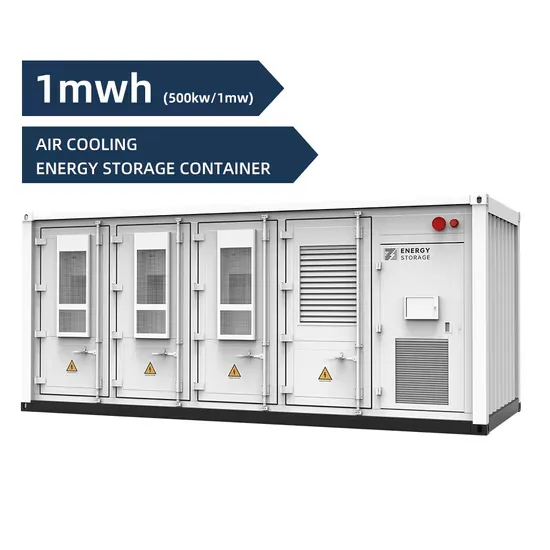

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

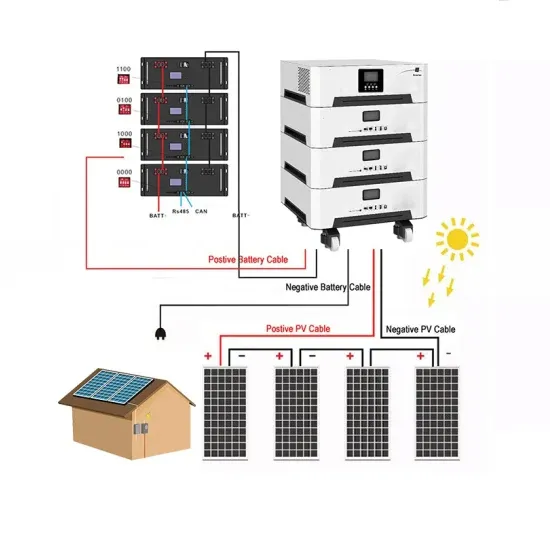

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.