How does the input voltage affect a power inverter?

Jul 3, 2025 · One of the most significant ways input voltage affects a power inverter is efficiency. Every inverter has an optimal input voltage range where it operates most efficiently. If the input

Get Started

32 Common Faults in Inverters and Their

Sep 18, 2023 · This can occur when the input voltage is too low or when there is a sudden increase in the load, a transient power failure, a failure of a hall

Get Started

General Inverter Troubleshooting | Magnum Dimensions

4 days ago · General Inverter Troubleshooting The following is a quick reference for Magnum Energy inverter/charger to diagnose typical symptoms. Always refer to your full user manual.

Get Started

inverter Error Codes

Feb 25, 2022 · ID09 – PvOVP – The input voltage is too high – Check whether too many PV modules are series connected in a PV string, thus the voltage

Get Started

Growatt FAQ | Find Troubleshooting Tips

Find answers and troubleshooting techniques to common questions about Growatt''s on-grid, off-grid, and storage inverters, monitoring systems, and EV chargers.

Get Started

On sunny days, Inverter switches off when DC voltage gets too high

May 28, 2023 · The technical info for this inverter is: Input DC (PV side) Recommended max PV power 8000w Max input voltage 600v Rated voltage 330v MPPT voltage range 90-520v Full

Get Started

Do Inverters Turn Off When Voltage is too low?

Oct 26, 2021 · Group, If my batteries drop too low and the grid is off will an inverter turn off (stop outputting AC current)? I want to verify it will shut off and not provide dangerously low voltage

Get Started

6. Error Indications

May 16, 2025 · If one or more of the LEDs ''bulk'', ''absorption'' or ''float'' flashes, then this flash must be in phase opposition to the ''inverter on'' LED, i.e. the flashing LEDs are off if the ''inverter on''

Get Started

Sizing an Inverter for a Solar Power System

Mar 31, 2023 · Therefore, it is important to carefully match the inverter''s input voltage to the battery bank voltage to ensure reliable and efficient operation of

Get Started

Growatt inverter error codes + troubleshooting

Feb 26, 2024 · Growatt inverters are widely used in solar energy systems in order to help convert the direct current (DC) from solar panels into the alternating

Get Started

5. Operation

Nov 2, 2022 · The inverter will wait 30 seconds and then resumes operation again. If after 3 restarts, the DC ripple voltage is still too high, the inverter will shutdown and will not attempt to

Get Started

These 32 Common Inverter Faults, Have You

3 days ago · Check if the input high voltage power supply exceeds the allowed maximum value (if the supply voltage is too high, adjust the transformer tap to

Get Started

Troubleshooting Power Inverter Issues – Online

Jul 20, 2025 · By spotting issues like an inverter not starting or having output voltage problems, you can fix them. This ensures you have power when you

Get Started

Common Solar Power Inverter Problems and How to Balance

Aug 6, 2024 · Overvoltage or Under voltage: Inverters can sometimes shut down if the voltage is too high or too low. Ensure the input voltage from the solar panels is within the acceptable

Get Started

Three Common Misconceptions About Grid-tied Inverters

Aug 27, 2024 · If the string voltage is too low, the inverter may struggle to reach its rated AC output voltage, reducing efficiency. Conversely, if the string voltage is too high, it may exceed

Get Started

A comprehensive guide to inverter voltage

Dec 18, 2024 · A: Low inverter output voltage can be caused by several things: low batteries, loose connections, internal malfunctions, high ambient

Get Started

How to fix, AC Frequency Out Of Range?

They will be able to help you out. The microinverter reports that the utility''s frequency is either too low or too high, as specified by applicable regional standards. AC frequency is the frequency

Get Started

Decoding Inverter Parameters (Part I)

Jan 25, 2025 · If the PV input voltage is too low, power loss in the inverter''s boost circuit increases. If the PV input voltage is too high, it can cause power losses

Get Started

Inverter Common Faults Solutions

Jan 21, 2025 · Inverter Common Faults Solutions1. Overcurrent Overcurrent is the most frequent alarm phenomenon of the inverter. (1) When restarting, the

Get Started

Inverter AC Input Voltage is too High

Jul 14, 2020 · For the AC high voltage error, the error is caused when the voltage exceeds what is set on the GS8048 -> AC Input tab. Default setting is 132V per leg or 264V across both legs.

Get Started

When choosing an inverter, what voltage ratings

Maximum input voltage is the threshold that your inverter can handle without damage. This value is particularly important when integrating solar panels with

Get Started

Inveter AC output voltage too high?

6 days ago · When I first got it, the output voltage was 129-130, so I ask the manufacture and they can I can adjust a POD inside and that has reduced it down to 125v (lowest it can go). I have

Get Started

Decoding Inverter Parameters (Part I)

Jan 25, 2025 · 3.Rated Input Voltage Definition: The recommended operating voltage of PV modules in series (MPP voltage). When the input current

Get Started

Inverter

May 3, 2022 · A: The inverter detected PV panel input voltage is too high. Please use multi-meter to measure PV panels'' voltage and then compare the value with the DC input voltage range

Get Started

The PV inverter screen shows that the PV voltage is too high

The input voltage range of the three-phase string inverter is 250-800V, and the recommended voltage after stringing is between 600-650V. In this voltage range, the inverter has high

Get Started

Is the higher the DC string voltage of the

If the string voltage is too high or too low, the string voltage is far away from the rated voltage value/range set by the inverter, and its output efficiency is

Get Started

Inverter too high output voltage than normal, problem?

Mar 14, 2023 · Hi, One of the inverter of my school generating peak AC voltage of around 280V. My country''s standard mains voltage is around 220 to 230V AC. I have noticed that some cell

Get Started

6 FAQs about [Inverter input voltage is too high or too low]

How many MPPT inputs does an inverter have?

Most inverters come with two MPPT inputs, allowing them to track two different arrays with different voltage profiles. Minimum startup voltage is the lowest voltage at which an inverter will begin operation. The minimum startup voltage 4 tells you the lowest point the inverter needs to begin functioning.

Does a 230 volt inverter work?

The unit is a charger inverter. The charger works 100% no problem there. By the way it is 230VAC 50Hz. Most lightweight inverters first convert the low voltage to a DC high voltage (isolated). For a "true sine wave" it should be around 350VDC as the peak of 230VAC is about 325V.

What happens if a solar inverter fails to start?

If the solar array’s voltage drops below this level, such as during cloudy or low-sunlight days, the inverter will fail to start. This is especially important for areas with variable weather conditions. A lower minimum startup voltage means the inverter can begin working sooner, even in less-than-ideal conditions.

How many kHz is a 230 volt inverter?

By the way it is 230VAC 50Hz. Most lightweight inverters first convert the low voltage to a DC high voltage (isolated). For a "true sine wave" it should be around 350VDC as the peak of 230VAC is about 325V. This voltage feeds a full bridge (at least 4 power switches required) and this full bridge is PWM modulated with about 20 kHz or higher.

What is maximum input voltage?

Maximum input voltage is the threshold that your inverter can handle without damage. This value is particularly important when integrating solar panels with varying output characteristics. If the solar array's voltage exceeds this limit, it can cause overheating, component failure, or even complete inverter damage.

What happens if a solar inverter overheats?

If the solar array's voltage exceeds this limit, it can cause overheating, component failure, or even complete inverter damage. As solar technology improves, panels often produce higher voltages, so it's important to select an inverter that can handle these surges, especially during periods of peak sunlight.

Related Articles

-

Small low voltage to high voltage inverter

Small low voltage to high voltage inverter

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Low frequency inverter plus high voltage

Low frequency inverter plus high voltage

-

Low voltage to high voltage inverter for construction sites

Low voltage to high voltage inverter for construction sites

-

Inverter voltage high and low

Inverter voltage high and low

-

Latvian high quality low voltage inverter manufacturer

Latvian high quality low voltage inverter manufacturer

-

High voltage and low voltage energy storage batteries

High voltage and low voltage energy storage batteries

-

Outdoor energy storage high and low voltage prices

Outdoor energy storage high and low voltage prices

-

The impact of high voltage on inverter

The impact of high voltage on inverter

-

High voltage inverter accessories

High voltage inverter accessories

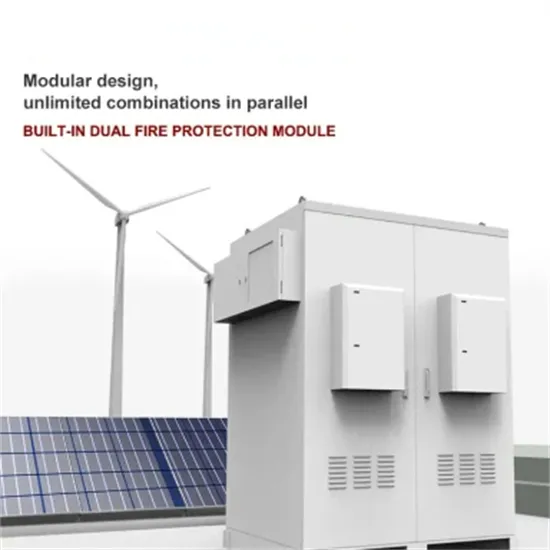

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.