A High speed, Low Voltage to High Voltage Level Shifter

Mar 27, 2012 · Abstract—The design of a high speed, low voltage to high voltage level shifter in a digital 1.2 V, 0.13μm CMOS technology is presented. The topology uses two differentially

Get Started

Inverters

Opt for low voltage inverters if safety, simplicity, and smaller systems are your focus. Choose high voltage inverters if efficiency, scalability, or long-distance transmission is a priority. Use low

Get Started

High-voltage VS Low-voltage Inverters: What''s the difference?

May 14, 2025 · High-voltage inverters are designed to work with DC voltages typically ranging from 150V to 600V or even more. They are common in larger residential or commercial solar

Get Started

High Voltage Inverter: What They Are, How They

You need a solar inverter for your solar system. However, not all the inverter are same. There are high voltage and low voltage inverter, which differ from the

Get Started

Low-voltage VS High-voltage Inverters: What''s the Difference

The distinction between low-voltage (LV) and high-voltage (HV) inverters extends beyond nominal voltage thresholds, encompassing design architectures, efficiency trade-offs, and application

Get Started

Comparison and Analysis of High Voltage Inverter and Low Voltage

Jul 28, 2022 · Adjustable output frequency AC motor drives with voltage levels below 690V are classified as low-voltage inverters. With the continuous maturity of low-voltage inverter

Get Started

Inverter Low Voltage Cutoff--Why SO low?

Aug 23, 2022 · I''m planning to buy two 12V inverters: a small one (about 500W) and a bigger one (about 2000 watts). I want to protect my 2 x 105AH FLA batteries, but have been surprised to

Get Started

High-voltage VS Low-voltage Inverters: What''s the difference?

What Are Low-voltage Inverters? Low-voltage inverters work with DC voltages ranging from 12V to 48V. These are often found in small systems like RVs, boats, cabins, and backup power for

Get Started

High Frequency Inverter vs Low Frequency

Aug 18, 2025 · Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

Get Started

How to Convert a Low Power Inverter to a High

Oct 23, 2014 · Here I have explained about a couple of simple circuit configurations which will convert any low power inverter to a massive high

Get Started

What is the difference between a high-voltage inverter and a low

Low voltage frequency converters are suitable for applications with low voltage (usually below 1kV) and are widely used in household appliances, small mechanical

Get Started

Simple High Voltage Generator: Low Voltage DC In, up to 30

Jan 30, 2021 · The high voltage section on the right may actually be constructed as a voltage multiplier rather than a single winding with multiple HV diodes. The rectifiers or multiplier,

Get Started

Differences and similarities between low-voltage inverters and high

The choice between a low-voltage inverter and a high-voltage inverter often depends on specific application requirements, including the scale of the operation, efficiency concerns, and safety

Get Started

Solis Launches High-Efficiency Low-Voltage

Jan 19, 2025 · November 7, 2024 – Solis, a global leader in PV inverter technology, has unveiled its latest innovation, the S6-EH3P(8-15)K02-NV-YD

Get Started

H Bridge Inverter Circuit using IC SG3525 and

Jan 9, 2025 · The SG3525-based H-Bridge inverter circuit converts low-voltage DC into high-voltage AC, making it ideal for use in applications like renewable

Get Started

Tackling Low-Voltage Signaling in Inverter

Jan 1, 2025 · Discover practical strategies for managing noise in high-power inverter designs. From component selection and PCB stack-up to routing

Get Started

A Low to High Voltage Tolerant Level Shifter for Low

Mar 7, 2022 · the interface of a low-voltage and high-voltage gates. The level shifter is a key circuit component in multi-voltage circuits and has important implementation [15]. For a chip

Get Started

How High Voltage Inverters Work

In this way, high voltage inverters can provide precise control over a wide range of power requirements, whether it is high frequency high voltage power for

Get Started

Learn About High vs. Low Frequency Inverters:

Feb 10, 2025 · What are high-frequency inverters? High-frequency inverters have a much higher internal switching frequency than conventional low-frequency

Get Started

Whats is a High Voltage Hybrid inverter? What are Key

Aug 8, 2024 · Explore the pivotal differences between high and low voltage hybrid inverters and how these variations can influence your choice in sustainable energy solutions. Understanding

Get Started

High Voltage Inverters: Understanding Its Benefits and

Jan 23, 2025 · A high-voltage inverter is designed to convert low-voltage DC power to high-voltage AC power efficiently. These inverters are commonly used in applications that require

Get Started

Whats is a High Voltage Hybrid inverter? What are Key

Aug 8, 2024 · Explore the pivotal differences between high and low voltage hybrid inverters and how these variations can influence your choice in sustainable energy solutions.

Get Started

[SOLVED]

Aug 14, 2011 · Most lightweight inverters first convert the low voltage to a DC high voltage (isolated). For a "true sine wave" it should be around 350VDC as the peak of 230VAC is about

Get Started

Differences and similarities between low-voltage inverters and high

Inverters are critical components in various applications ranging from renewable energy systems to electric vehicles, converting direct current (DC) into alternating current (AC). The choice

Get Started

The role and difference between high voltage

Sep 12, 2024 · Low-voltage inverters are smaller and less expensive than high-voltage inverters, and are easier to operate and maintain. To summarize, high

Get Started

High Voltage vs Low Voltage

May 31, 2022 · If this doesn''t fit, please ignore. If you really meant low frequency vs high frequency, then compare it in layman''s terms to an old-school muscle car with a big engine

Get Started

Medien Tech Talk

Oct 13, 2021 · Source: Company information. Notes: HV: High Voltage. CO2 savings relate to "tank to wheel" potential vs. pure combustion vehicle based on WLTP (Worldwide Harmonized

Get Started

High-voltage VS Low-voltage Inverters: What''s the difference?

Confused about high-voltage vs low-voltage inverters? This easy-to-read guide explains the differences, pros, cons, and real-world uses—perfect for anyone exploring solar power, off-grid

Get Started

High Voltage Inverter Design

Figure 5/SCM inverter control system Epilogue By the PWM control chip and high voltage driver IR2110 SG3525A consisting frequency inverter, small size, easy

Get Started

Is there a difference between a high voltage inverter and a low voltage

Jan 5, 2024 · The choice between low-voltage and high-voltage hybrid inverters depends on system size, power requirements, and availability and investment opportunities. Low voltage is

Get Started

High voltage DC-AC sine wave inverters accept

High voltage DC-AC sine wave inverters accept wide input ranges of 450V to 800Vdc. High frequency PWM technology enables high efficiency, compact

Get Started

Understanding inverter voltage

Jan 10, 2024 · In this article, let''s embark on a comprehensive journey to unravel the mysteries surrounding inverter voltage, exploring its nuances, applications,

Get Started

Revealing the Differences and Advantages

In the process of construction and operation of photovoltaic power stations, choosing an appropriate grid connection method is crucial. High-voltage grid

Get Started

6 FAQs about [Small low voltage to high voltage inverter]

What is a low frequency power inverter?

A low frequency power inverter is a type of inverter that uses high speed power transistors to invert DC to AC at the same frequency (60 Hz or 50 Hz) as the AC sine wave output. These inverters are known for producing a low frequency hum.

What is a low cost 1000w power inverter?

This power inverter, with a low cost, produces modified sine wave 1000w continuous and 2000w peak power, converting 24V DC to 110V/220V AC power. It is a low cost option that can be used for car, home, RV, or anywhere that AC power is needed. The inverter features durable housing, a built-in cooling fan, and multi-protections for safe and effective use.

What is a low cut-off voltage for an inverter?

The low cut-off of the inverter can be set at the load voltage of 170 volts for the tube light, fan, etc. So the tube light and fan will not be switched off until the voltage goes below 170 volts. If there is no load connected to the output of the inverter, the output voltage is 270 to 290 volts.

How many watts is a small inverter?

You'll find a plenty of small and medium sized inverters in the market ranging from 100 to 500 watts, the same may be seen posted in this blog. Upgrading or converting such small or medium power inverters into massive high power inverter in the order of kvas may look quite a daunting and complex, but actually it's not.

How to upgrade a low power inverer circuit to a higher power?

The above explained ideas for upgrading a low power inverer circuit to a higher power version can be implemented to any desired level, simply by adding several MOSFETs in parallel. Adding MOSFETs in parallel is actually easier than adding BJT in parallel.

How do inverter topologies work?

All inverter topologies basically incorporate an oscillator frequency which is then amplified using power devices to high current levels before dumping into the step-up transformer for the final voltage boosting procedures.

Related Articles

-

Inverter input voltage is too high or too low

Inverter input voltage is too high or too low

-

Inverter voltage high and low

Inverter voltage high and low

-

Low frequency inverter plus high voltage

Low frequency inverter plus high voltage

-

Latvian high quality low voltage inverter manufacturer

Latvian high quality low voltage inverter manufacturer

-

Bulgaria low voltage inverter price

Bulgaria low voltage inverter price

-

Doxin inverter voltage is low

Doxin inverter voltage is low

-

Low voltage inverter 220v to 36v

Low voltage inverter 220v to 36v

-

5kW high voltage inverter

5kW high voltage inverter

-

Inverter voltage high with voltage regulation

Inverter voltage high with voltage regulation

-

Solar Panel High Voltage Inverter

Solar Panel High Voltage Inverter

Commercial & Industrial Solar Storage Market Growth

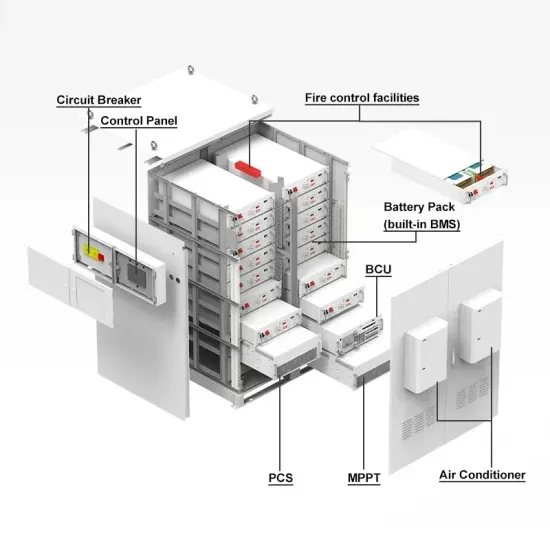

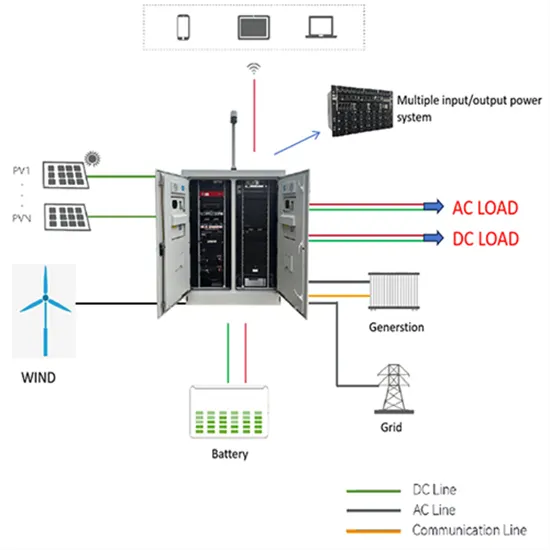

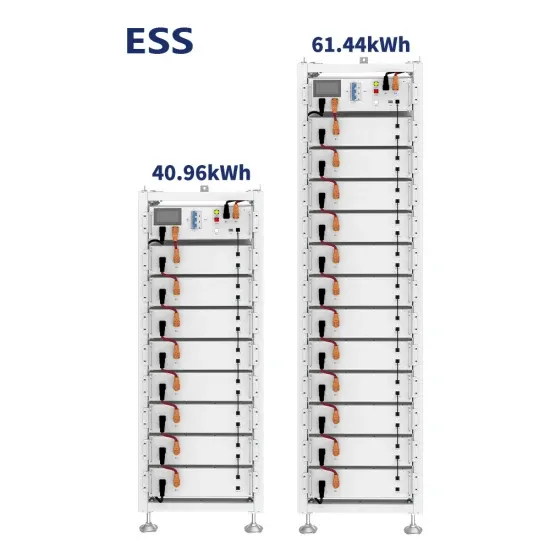

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.