Lithium Battery Pack Price and Lithium Battery Price Factors

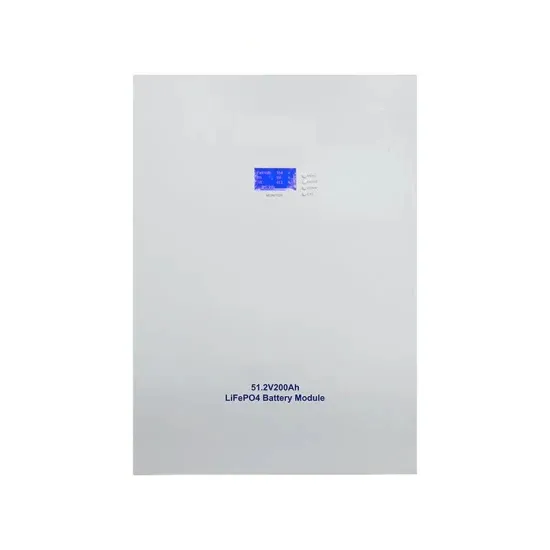

lithium batteries is mainly composed of battery cells, BMS and structural parts, plus the cost of pack, aging and management.At the same time due to the technical difficulty of the product,

Get Started

Design and Cost Modeling of High Capacity Lithium Ion Batteries

Jan 1, 2020 · This study focuses on adopting Battery Performance and Cost model (BatPaC) to provide a comprehensive design of a high capacity lithium ion battery (LIB) pack with a silicon

Get Started

Wave of Decline Sweeps Lithium-Ion Battery Pack Pricing, in

Mar 6, 2025 · Lithium-ion battery pack prices dropped 20% in 2024, reaching $115/kWh. EV battery prices dip below $100/kWh—explore the trends behind this decline.

Get Started

The Handbook of Lithium-Ion Battery Pack Design

Abstract Lithium-ion (Li-ion) batteries are everywhere today. introduces the topic of Li-ion batteries and Li-ion battery design to the reader and outlines the flow of the book with the intention of

Get Started

news: Bloomberg: Battery prices are falling again

28 November 2023 Following unprecedented price increases in 2022, battery prices are falling again this year, according to BloombergNEF''s annual lithium-ion battery price survey. Average

Get Started

Design and optimization of lithium-ion battery as an efficient

Nov 1, 2023 · Review article Design and optimization of lithium-ion battery as an efficient energy storage device for electric vehicles: A comprehensive review

Get Started

What Are The Implications Of $66/kWh Battery Packs In China?

Dec 26, 2024 · China''s battery packs plummet in price again. Hydrogen prices didn''t decline and BNEF triples its estimates for future costs. The implications are huge.

Get Started

Redway Battery Custom Lithium Battery Pack

Redway Custom Lithium Battery and Design Redway has industry-leading battery custom design capabilities, whether UL, IEC or CE certification. Redway

Get Started

What Affects the Cost of Custom Lithium Battery Packs?

May 28, 2025 · Custom lithium battery packs are not off-the-shelf components. They are engineered systems—built to meet your exact voltage, capacity, safety, and integration needs.

Get Started

What Factors Influence Custom Battery Pack Manufacturing Prices?

Feb 18, 2025 · Answer: Custom battery pack manufacturing prices depend on cell chemistry, capacity, design complexity, safety certifications, and order volume. Lithium-ion batteries cost

Get Started

Lithium-Ion Battery Pack Prices See Largest Drop Since

New York, December 10, 2024 – Battery prices saw their biggest annual drop since 2017. Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour,

Get Started

Development perspectives for lithium-ion battery cell

Dec 5, 2022 · These battery characteristics primarily follow from the cell to pack level battery design. As one central result, the market has witnessed a wide variety of manufacturer- and

Get Started

What Are The Implications Of $66/kWh Battery Packs In China?

Dec 26, 2024 · A full BESS price of $66 per kWh is going to be a bit higher for an EV battery pack, but not that much. These are standard LFP cells, which means much lower likelihood of

Get Started

How Lithium Battery Prices Are Changing In

Jun 20, 2025 · Lithium battery price in 2025 averages $151/kWh, with EV packs from $4,760–$19,200. Prices keep falling due to tech advances and lower

Get Started

EU expects battery pack price of less than

Nov 26, 2024 · The prediction was included in the "Battery technology in the European Union: 2024 status report on technological development, trends,

Get Started

Benchmarking Battery Packs

Aug 13, 2025 · The battery pack database is now available as an excel file via a download. This is $15 and gives high level data for a number of battery packs

Get Started

Voltx.ai Software: design Battery Packs Online

4 days ago · Voltaplex Energy launched Voltx.ai Alpha, a battery design automation cloud software that will enable engineering teams to rapidly

Get Started

Lithium-ion battery pack prices rise | Article Page

Dec 14, 2022 · Rising raw material and battery component prices and soaring inflation have led to an increase in lithium-ion battery pack prices, according to a recent survey from

Get Started

Lithium Ion Battery Pack Prices: The Role of Innovation and

Jun 19, 2024 · Understanding how innovation and efficiency impact the pricing of lithium-ion battery packs can help businesses make informed decisions. This article explores these key

Get Started

Battery Pack Prices Drop Below Key Threshold

Mar 6, 2025 · The global average price of EV battery packs has dropped below $100 per kilowatt-hour, a key milestone for EV price competitiveness, with

Get Started

Record-Low EV Battery Prices in 2023

Dec 1, 2023 · On average, LFP cells were 32% cheaper than lithium nickel manganese cobalt oxide (NMC) cells in 2023," BNEF writes. Forecast: Record Low Battery Prices Again In 2024,

Get Started

IEA Report: LFP Dominates as EV Battery Prices Fall

May 20, 2025 · IEA report highlights major shifts in EV battery prices, rising LFP adoption, and China''s increasing dominance in global manufacturing.

Get Started

Pack to Cell Cost Ratio

Apr 30, 2025 · Weighted average survey value includes 343 data points from passenger cars, buses, commercial vehicles, and energy storage. The Volta

Get Started

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get Started

BNEF reports record low price for Li-ion battery

Dec 13, 2024 · Research provider BloombergNEF (BNEF) released a new report on the price level of lithium-ion battery packs and noted prices have dropped

Get Started

Lithium-Ion Battery Costs: Manufacturing Prices,

Mar 16, 2025 · The cost to make lithium-ion batteries ranges from $40 to $140 per kWh. Prices depend on battery chemistry, like LFP or NMC, and geography, such as China or

Get Started

BloombergNEF annual battery price survey finds

Dec 1, 2021 · Lithium-ion battery pack prices, which were above $1,200 per kilowatt-hour in 2010, have fallen 89% in real terms to $132/kWh in 2021,

Get Started

Lithium Battery Manufacturer and Supplier in

Our Lithium ion Battery Products Buzzup can manufacture and customize all kinds of lithium ion battery according to your request. Mainly cover home

Get Started

Lithium-ion battery pack prices increase due to

BloombergNEF (BNEF) has noticed that raw material and battery component prices have been rising steadily since it began tracking the market in 2010,

Get Started

Tesla LFP Model 3

Jan 9, 2024 · The Tesla LFP Model 3 is quite a landmark battery pack for Tesla. Up until now everything has revolved around chasing cylindrical NCA cells.

Get Started

6 FAQs about [Lithium battery pack design price]

What are the materials costs of a battery pack?

The annual requirements and costs of the materials and purchased items are determined by the design model for the battery performance. For a battery pack, the major contributions to the materials costs include electrode active materials, separator, electrolyte, current collectors, and so on.

Why did lithium-ion battery prices drop 20% from 2023?

Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis by research provider BloombergNEF (BNEF). Factors driving the decline include cell manufacturing overcapacity, economies of scale, low metal and component prices, adoption of lower-cost lithium-...

How much does an EV battery pack cost?

A full BESS price of $66 per kWh is going to be a bit higher for an EV battery pack, but not that much. These are standard LFP cells, which means much lower likelihood of thermal runaway. Assuming they get to $80 per kWh for EV LFP battery packs, then the US tariff of 25% makes them about $100 per kWh.

How is battery manufacturing cost scaled?

The manufacturing costs are scaled from a baseline plant, which has an annual production rate of 100,000 and involves the size, speed, number of units, direct labor, and depreciation of the capital cost for each processing step for the production of the battery pack.

How much does a battery cost in China?

On a regional basis, average battery pack prices were lowest in China, at $94/kWh. Packs in the US and Europe were 31% and 48% higher, reflecting the relative immaturity of these markets, as well as higher production costs and lower volumes.

What is cost modeling of NMC-SiNW battery pack?

Cost modeling of the NMC-SiNW battery pack The cost modeling for a specified battery pack accounts for materials costs, purchased items costs, manufacturing costs, and battery pack integration costs . The annual requirements and costs of the materials and purchased items are determined by the design model for the battery performance.

Related Articles

-

Lithium battery pack price in Kuala Lumpur

Lithium battery pack price in Kuala Lumpur

-

Moldova professional lithium battery pack reference price

Moldova professional lithium battery pack reference price

-

Creo design lithium battery pack

Creo design lithium battery pack

-

Praia regular lithium battery pack factory price

Praia regular lithium battery pack factory price

-

Montevideo professional lithium battery pack reference price

Montevideo professional lithium battery pack reference price

-

Rabat good lithium battery pack factory price

Rabat good lithium battery pack factory price

-

Lithium battery box pack design

Lithium battery box pack design

-

Victoria Power Tools Lithium Battery Pack

Victoria Power Tools Lithium Battery Pack

-

Lithium tool battery price

Lithium tool battery price

-

Solar panel 12v lithium battery pack

Solar panel 12v lithium battery pack

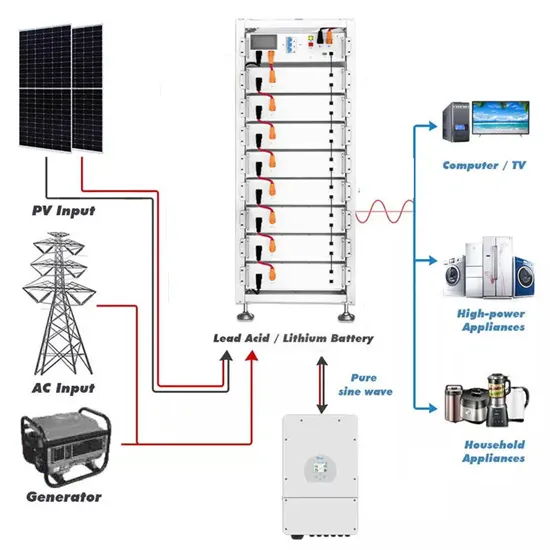

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

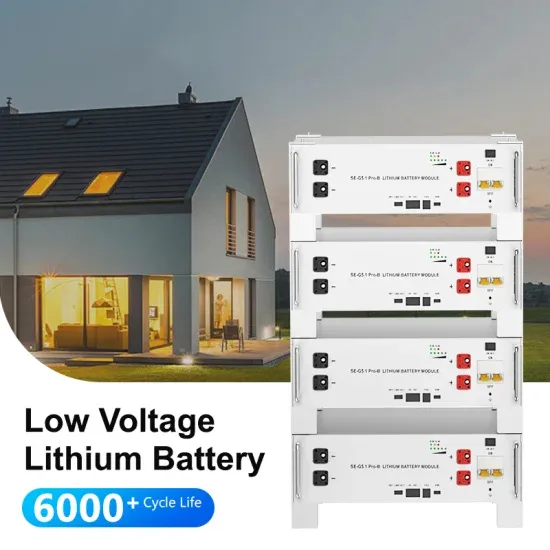

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.