The Handbook of Lithium-Ion Battery Pack Design

Abstract Lithium-ion (Li-ion) batteries are everywhere today. introduces the topic of Li-ion batteries and Li-ion battery design to the reader and outlines the flow of the book with the intention of

Get Started

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get Started

Lithium Battery Designer

Lithium Battery Designer Application ID: 51301 This app can be used as a design tool to develop an optimized battery configuration for a specific application.

Get Started

Optimization and Structural Analysis of Automotive

Nov 9, 2024 · Through weight reduction and structural optimization, an innovative power battery pack design scheme is proposed, aiming to achieve a more eficient and lighter electric vehicle

Get Started

How to design battery packs, tutorial for Design Engineers

April 21, 2023 Engineering Guidelines for Designing Battery Packs Custom design and manufacture of state-of-the-art battery chargers, battery packs, UPS, and power supplies

Get Started

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack. Before diving into the design process, it''s crucial to

Get Started

Creo Energy Storage Tutorial: Designing Next-Gen Systems

Sep 19, 2020 · Let''s cut to the chase – the global energy storage market is booming faster than a Tesla battery on autopilot, hitting $33 billion annually with 100 gigawatt-hours of electricity

Get Started

Optimization of Retired Lithium-Ion Battery Pack

Oct 24, 2024 · This study introduces a sophisticated methodology that integrates 3D assessment technology for the reorganization and recycling of retired

Get Started

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

Get Started

Battery Pack Thermal Design

Aug 17, 2016 · Battery Pack Thermal Design Ahmad Pesaran National Renewable Energy Laboratory Golden, Colorado NREL/PR-5400-66960 NREL is a national laboratory of the U.S.

Get Started

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · lls are connected in parallel to form a battery submodule, and 13 battery submodules are connected in series to form a battery pack. The battery pack design process

Get Started

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · At the same time battery pack technologies have improved and become simpler. These improvements have enabled an entirely new generation of EVs and applications.

Get Started

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · Abstract - Lithium-ion batteries are used for their high energy efficiency and are frequently used by electric car manufacturers typically employ them (EVs). However, abrupt

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · This project offers a detailed overview of the process involved in designing a mechanical structure for an electric vehicle''s 18 kWh battery pack.

Get Started

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Nowadays, battery design must be considered a multi-disciplinary activity focused on product sustainability in terms of environmental impacts and cost. The paper reviews the

Get Started

ANALYSIS OF A LITHIUM-ION BATTERY COOLING

Jul 22, 2022 · Lithium-ion battery (LIB) has received considerable attention for traction uses due to the higher energy density (70-170 Wh/kg), power capabilities, lowest standard reduction

Get Started

Simulation-driven EV Battery Pack Design And

May 7, 2020 · In the last decade, the electric vehicle (EV) industry has grown tremendously from just few offerings to today, when every automaker is

Get Started

Factors Influencing the Design of Custom

Apr 30, 2024 · As experts in custom battery pack design, we understand the intricate details that go into creating high-performance and reliable power

Get Started

Crashworthiness Evaluation of Electric Vehicle

May 1, 2024 · The CAD model of the battery pack is developed in Creo parametric design software. The use of a honeycomb structure enabled the

Get Started

PTC Creo Skills Showcase: Milwaukee M12 REDLITHIUM XC 4.0 Battery

Mar 18, 2016 · The Milwaukee M12™ REDLITHIUM™ XC 4.0 Extended Capacity Battery Pack was modeled using Part Modeling in Creo Parametric Modeled in Creo Parametric 3.0

Get Started

How to Design a Custom Battery Pack: A Step-by-Step Guide

This comprehensive guide walks engineers through the intricate process of designing a custom battery pack, offering a step-by-step approach with practical insights and technical

Get Started

Cell-to-Pack Design in Lithium-ion Batteries

Among the many breakthroughs, the cell-to-pack (CTP) design has emerged as a game-changer, offering a wealth of advantages over traditional battery pack

Get Started

How Battery Pack Design Influences Portable Oxygen

11 hours ago · You rely on advanced lithium-ion chemistries for portable oxygen concentrator battery pack design because they deliver the best balance of safety, performance, and

Get Started

Cell to Pack Ratio vs Cell Capacity

Mar 16, 2025 · We would expect to see an improvement in Cell to Pack Ratio vs Cell Capacity. That means that as the cell get larger so the use of the pack

Get Started

Lithium Battery Shipping Boxes & Packaging Kits

4 days ago · Creopack is a trusted provider of UN-approved lithium battery shipping boxes. Ensure compliant transport with our shipping kits for lithium

Get Started

6 FAQs about [Creo design lithium battery pack]

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

What is a battery design platform?

A design platform could integrate simulations, data-driven, and life cycle methods. Nowadays, battery design must be considered a multi-disciplinary activity focused on product sustainability in terms of environmental impacts and cost. The paper reviews the design tools and methods in the context of Li-ion battery packs.

What are Li-ion batteries used for?

During this period, Li-ion batteries have been used in different fields such as electronic devices, smart-home, transportation, etc. The paper analyzes the design practices for Li-ion battery packs employed in applications such as battery vehicles and similar energy storage systems.

Why do we need advanced design tools for Li-ion batteries?

Li-ion batteries require advanced design tools to satisfy all requirements and objectives due to the complexity of the subject. Heuristic methods and numerical approaches are insufficient to support the design project of future battery packs, in which optimization and advanced analysis are essential.

How many battery submodules are connected in a battery pack?

lls are connected in parallel to form a battery submodule, and 13 battery submodules are connected in series to form a battery pack. The battery pack design process mainly includes positioning and connection of battery cells, heat dissipation mechanism, cabl

What is the energy density of a lithium-ion battery module?

ergy density of a lithium-ion battery module can reach 150-200Wh/kg, which is higher compared t the batteries of other chemistries. Therefore, the lithium-ion battery has become the mainstream in the field of electric vehicles. The objective in this research is to develop a 48 V battery pack with a high energy den

Related Articles

-

Lithium battery box pack design

Lithium battery box pack design

-

Lithium battery pack design price

Lithium battery pack design price

-

Lithium battery pack small cells

Lithium battery pack small cells

-

8How many mAh is the lithium battery pack

8How many mAh is the lithium battery pack

-

240v lithium battery pack

240v lithium battery pack

-

10 How many mAh does a lithium battery pack have

10 How many mAh does a lithium battery pack have

-

How much is the Lima lithium battery pack

How much is the Lima lithium battery pack

-

Are there any lithium battery pack companies in Namibia

Are there any lithium battery pack companies in Namibia

-

Lithium battery pack series voltage is low

Lithium battery pack series voltage is low

-

Lithium battery pack can be partially replaced

Lithium battery pack can be partially replaced

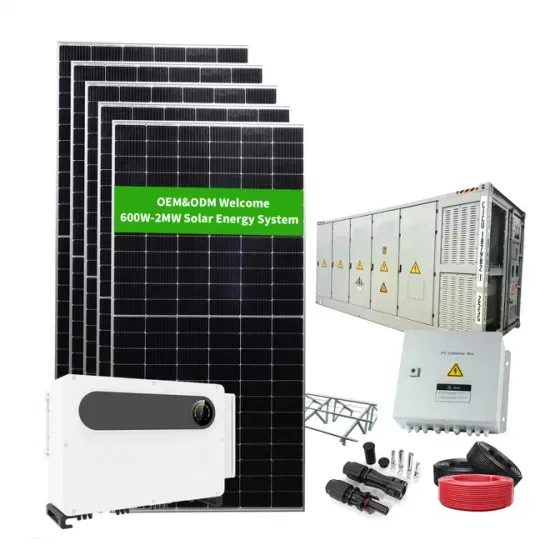

Commercial & Industrial Solar Storage Market Growth

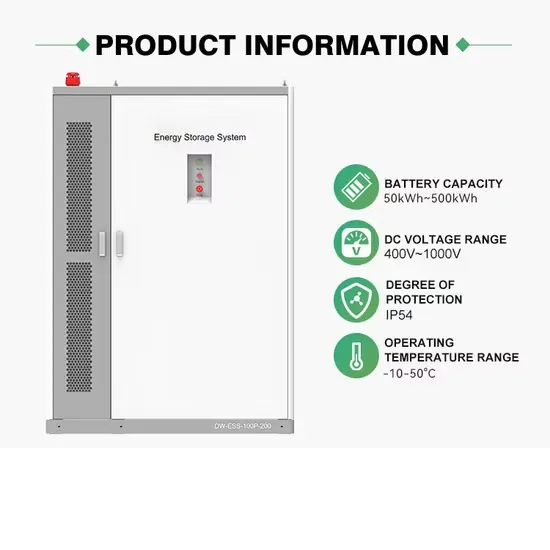

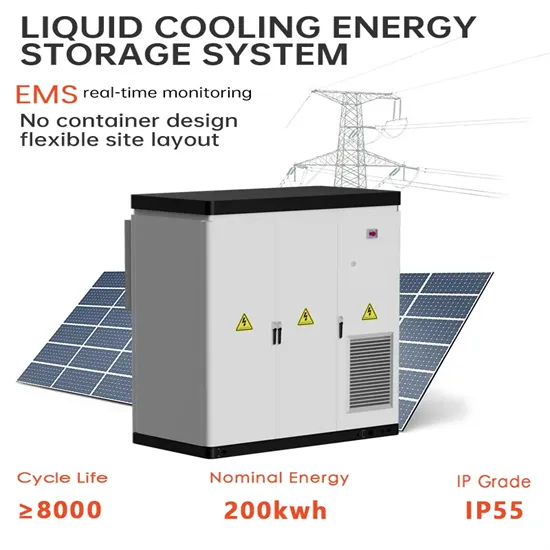

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

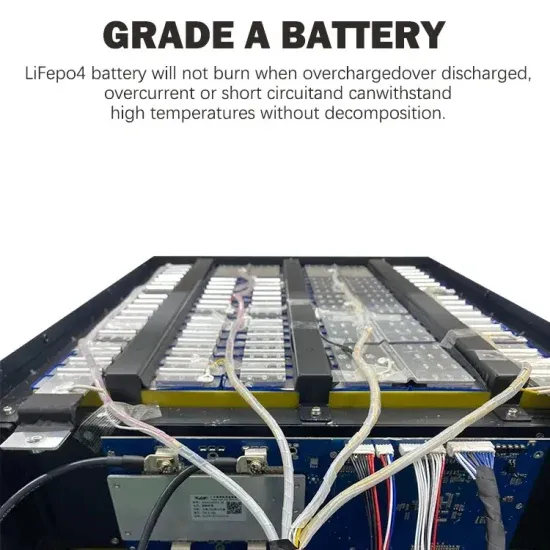

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.