Simulation and analysis of air cooling configurations for a

Mar 1, 2021 · The air-cooling BTMS has been extensively investigated and presented in the literature, mostly for the optimization of the airflow channel and manifold configurations aiming

Get Started

Optimal Structure Design and Temperature Control Strategy of Air

May 11, 2025 · A reliable battery thermal management system is essential to maintain optimal battery performance. In this article, simulation is carried out for the design of air-cooled battery

Get Started

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Nowadays, battery design must be considered a multi-disciplinary activity focused on product sustainability in terms of environmental impacts and cost. The paper reviews the

Get Started

A review of air-cooling battery thermal management systems for electric

Jul 31, 2021 · The existing research work on improvement of the air-cooling BTMS can be classified into five categories: improvement on battery pack design, cooling channel

Get Started

A Review of Advanced Cooling Strategies for

Jun 28, 2023 · The present review summarizes numerous research studies that explore advanced cooling strategies for battery thermal management in EVs.

Get Started

Study on The Cooling Performance By Cooling Air Channel Design For Air

Dec 20, 2024 · Computational fluid dynamics (CFD) analysis results present an optimal design of the cooling air passage of a battery pack based on the area of the same cooling air flow

Get Started

Development and Analysis of a Modified H-Type

Apr 16, 2025 · Abstract. Thermal management of lithium-ion batteries is an important design consideration for electric vehicles (EVs) as it affects the

Get Started

Liquid Immersion Cooling for Battery Packs

Jul 21, 2025 · Liquid Immersion cooled battery Packs, direct cooling, dielectric cooling, Battery Thermal Management, advanced battery pack cooling methods.

Get Started

Optimizing thermal performance in air-cooled Li-ion battery packs

Jul 15, 2025 · There are a number of well-liked, innovative air-cooled techniques that improve cooling performance without compromising cost, including the placement of ducts, fins, battery

Get Started

Low-Cost Air-Cooling System Optimization on

Nov 28, 2021 · This work aimed to optimize lithium-ion battery packing design for electric vehicles to meet the optimal operating temperature using an air

Get Started

Comparison and optimization of an air cooling design for

Sep 28, 2023 · Comparison and optimization of an air cooling design for lithium-ion battery packs by using an electrochemical-thermal coupled model | IEEE Conference Publication | IEEE Xplore

Get Started

Pouch Cell Cooling

Jan 13, 2023 · There is no cooling other than radiation and convection from the outer surface of the pack to the environment. Air flow cooling increases over

Get Started

Improving the air-cooling performance for lithium-ion battery packs

Feb 25, 2023 · Air-cooling battery thermal management system (BTMS) is commonly used to maintain the performance and safety of lithium-ion battery packs in electric

Get Started

Cooling Characteristics and Optimization of an Air-Cooled Battery Pack

Jan 31, 2025 · In this paper, we proposed a forced-convection air cooling structure aiming at uniform temperature distribution and reducing the maximum temperature. The initial step was

Get Started

Cooling performance of battery pack as affected by inlet

Nov 1, 2022 · Air cooling is one of the most commonly used solutions due to low cost and high reliability [6]. Xie et al. [7] focused on the influences of inlet angle, outlet angle and channel

Get Started

Development and Analysis of a Modified H-Type

Apr 16, 2025 · Given the thermal vulnerability of lithium-ion batteries when subjected to high charging and discharging rates, effective cooling designs for

Get Started

Configuration, design, and optimization of air-cooled battery

Jun 1, 2020 · Specifically, this study investigates and reviews air-cooled BTMS techniques (passive and active) and design parameter optimization methods (either via iteration or

Get Started

Design and Optimization of Air-Cooled Structure in Lithium-Ion Battery Pack

Mar 19, 2025 · This paper focuses on the thermal management of lithium-ion battery packs. Firstly, a square-shaped lithium iron phosphate/carbon power battery is selected, and a battery

Get Started

EV Battery Cooling System – How Does It Work?

Mar 10, 2025 · Learn how EV battery cooling system protect performance and safety. Explore methods, challenges, and best practices.

Get Started

Innovative heat dissipation solution for air-cooled battery pack

Apr 30, 2025 · Initially, the battery pack reached a temperature of 80°C under load, which was reduced to 60°C with air cooling. The introduction of an additional cooling fan at the top further

Get Started

Electric Vehicle Coolant and Cooling Systems

6 days ago · Cooling lithium-ion battery packs is vital, as is evaluating which battery cooling system is most effective and the right electric vehicle coolant to

Get Started

Optimization design for improving thermal performance of T-type air

Dec 15, 2021 · For air-based BTMS, the key design idea is to construct a reasonable structure so that the cooling airflow can be evenly distributed in the system, so as to achieve the purpose

Get Started

Battery Cooling Tech Explained: Liquid vs Air

May 9, 2025 · Thus, air cooling works best for small to moderate batteries or where cost is paramount. It is common in older EVs, like early Nissan Leaf,

Get Started

Improving the air-cooling performance for lithium-ion battery packs

Feb 25, 2023 · Battery thermal management systems can be divided into four categories according to different heat transfer media: air cooling, liquid cooling, phase change material

Get Started

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · Choosing the right cooling mechanism for a lithium-ion battery pack for electric vehicles and developing an appropriate cooling control plan to maintain the heat contained

Get Started

Battery Pack Thermal Design

Aug 17, 2016 · Battery Pack Thermal Design Ahmad Pesaran National Renewable Energy Laboratory Golden, Colorado NREL/PR-5400-66960 NREL is a national laboratory of the U.S.

Get Started

A review of power battery cooling technologies

May 1, 2025 · Theoretical methods for enhancing the cooling effect are analyzed based on governing equations. The main cooling technologies are reviewed, including air cooling, liquid

Get Started

A design optimization study of an air-cooling

Aug 1, 2022 · Air cooling is a highly cost-effective method for the battery thermal management systems due to its simple structure, high reliability and low

Get Started

What is air-cooled battery cooling? – TYCORUN

Mar 30, 2022 · The thermal management of the power battery with air as the medium is to let the air traverse the battery pack to take away or bring heat to

Get Started

Design and Optimization of Cooling Plate for Battery

Dec 28, 2024 · Pranav Anande Pune, India Abstract — Efficient battery cooling is critical for electric vehicle safety and performance, yet existing methods like air and liquid cooling face

Get Started

(PDF) A Review of Advanced Cooling Strategies

Jun 28, 2023 · Research studies on phase change material cooling and direct liquid cooling for battery thermal management are comprehensively reviewed

Get Started

Optimization study of a Z-type airflow cooling system of a

Jun 17, 2024 · The present study aims to optimize the structural design of a Z-type flow lithium-ion battery pack with a forced air-cooling system known as BTMS (battery therm

Get Started

Battery Cooling Techniques in Electric Vehicle

Air Cooling Types: Passive and active air cooling. Working: Uses ambient or forced air to dissipate heat. Fans may be employed for active air cooling.

Get Started

Cooling of lithium‐ion battery pack using different

Jan 2, 2024 · The rated temperature and its uniformity of lithium-ion (Li-ion) battery (LIB) pack are the main demands for safe and efficient operation. This paper investigates an air cooling

Get Started

Battery Pack Design: Efficient & Safe Energy

Mar 15, 2025 · Learn how to design a high-performance battery pack with the right cell configuration, cooling system, and safety features.

Get Started

6 FAQs about [Battery pack air cooling design]

How can a lithium-ion battery pack improve cooling performance?

Soltani et al. developed a 3D-thermal Lithium-ion battery pack model to obtain an optimal cooling performance by arranging and combining three parameters: battery distance, air velocity and fan position. The optimal simulation result was a 5 mm inter-cell distance with two fans on one side blowing the air flow at a velocity of 5 m/s.

Can Z-type flow lithium-ion battery pack have a forced air-cooling system?

Ashoke De; Optimization study of a Z-type airflow cooling system of a lithium-ion battery pack. 1 June 2024; 36 (6): 067119. The present study aims to optimize the structural design of a Z-type flow lithium-ion battery pack with a forced air-cooling system known as BTMS (battery thermal management system).

Does air cooling reduce temperature in battery thermal management systems (BTMS)?

Air cooling techniques using MVGs inside the input duct channel have shown significant thermal performance in terms of temperature reduction in battery thermal management systems (BTMS). Furthermore, almost all the modified BP designs achieved significant temperature drops of 7 °C for individual cells within the BP at a 2.5C rate.

How to reduce the maximum temperature difference in a battery pack?

Based on the “Z-type” cooling channel design, Hong et al. proposed a secondary ventilation outlet hole design to reduce the maximum temperature difference. The locations of the secondary ventilations were suggested to be on the battery pack case surfaces opposite to the cooling channels with the highest temperature.

Can air cooling reduce the maximum temperature of lithium ion batteries?

Yu et al. developed a three-stack battery pack with the stagger-arranged Lithium-ion battery cells on each stack with two options: natural air cooling and forced air cooling as shown in Fig. 2. The experimental results showed that the active air cooling method could reduce the maximum temperature significantly. Fig. 2.

Do lithium-ion batteries need a cooling design?

Given the thermal vulnerability of lithium-ion batteries when subjected to high charging and discharging rates, effective cooling designs for battery packs are necessary. The current work proposes a cooling design with better heat dissipation and maximum temperature difference (ΔT max).

Related Articles

-

Battery cabinet forced air cooling system design

Battery cabinet forced air cooling system design

-

Power lithium battery pack cooling

Power lithium battery pack cooling

-

Liquid Cooling Battery Cabinet Design

Liquid Cooling Battery Cabinet Design

-

Battery pack bms design

Battery pack bms design

-

Lithium battery pack design price

Lithium battery pack design price

-

Lithium battery box pack design

Lithium battery box pack design

-

Battery pack mechanical structure thermal design

Battery pack mechanical structure thermal design

-

Produce 12v40ah battery pack using lithium battery

Produce 12v40ah battery pack using lithium battery

-

How much is the lithium battery pack in Solomon Islands

How much is the lithium battery pack in Solomon Islands

-

Vatican makes solar lithium battery pack

Vatican makes solar lithium battery pack

Commercial & Industrial Solar Storage Market Growth

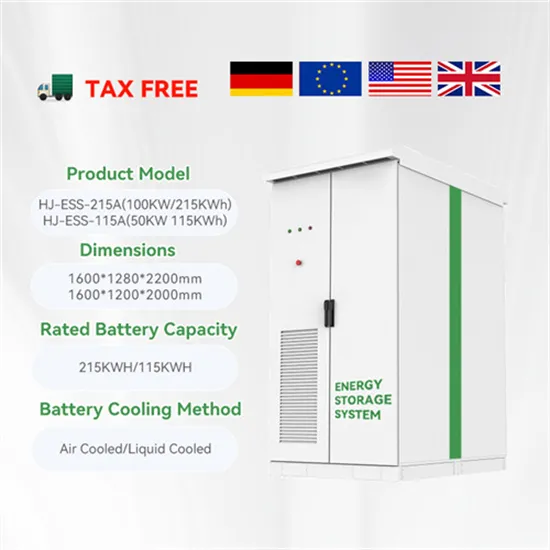

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.