Design and Optimization of Air-Cooled Structure in Lithium-Ion Battery Pack

Mar 19, 2025 · This paper focuses on the thermal management of lithium-ion battery packs. Firstly, a square-shaped lithium iron phosphate/carbon power battery is selected, and a battery

Get Started

Battery Pack Thermal Design

Aug 17, 2016 · Isothermal conduction calorimeters along with battery testers are best equipment to measure heat generation at various current rates, temperatures, and states of charge (SOCs)

Get Started

Thermal management of lithium-ion battery packs in electric

A 3-D model of a 36-cell lithium-ion battery pack was developed and simulated in COMSOL Multiphysics, and the system''s thermal performance was evaluated under various conditions,

Get Started

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · install partitions between BMS and cells check if the pack is designed to be able to avoid thermal runaway analyze the battery pack''s thermal distribution and its effect on the

Get Started

An integrated cell-to-pack design based on an origami

Jul 1, 2024 · To meet the requirements of thermal and mechanical performance of the battery pack, this paper proposes an integrated approach to designing a battery pack with an origami

Get Started

Fundamentals of Battery Pack Design | Ansys Innovation

Discover the intricate process of designing a battery pack for electric vehicles, focusing on electrical design, mechanical robustness, and thermal stability.

Get Started

Review on Battery Packing Design Strategies for

Dec 14, 2022 · In the last decades of electric vehicle (EV) development, battery thermal management has become one of the remaining issues that must be

Get Started

Battery Pack and Underbody: Integration in the

Mar 6, 2023 · The integration of the battery pack''s housing structure and the vehicle floor leads to a sort of sandwich structure that could have beneficial

Get Started

Review of mechanical design and strategic placement technique

Jul 1, 2016 · In an electric vehicle (EV), thermal runaway, vibration or vehicle impact can lead to a potential failure of lithium-ion (Li-ion) battery packs due to their high sensitivity to ambient

Get Started

Components and Functions

Nov 29, 2023 · A good way of thinking about battery pack design is to look at components and functions: Electrical, Thermal, Mechanical, Control and Safety.

Get Started

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · The battery thermal management technology in electric vehicles (EVs) and hybrid electric vehicles (HEVs) should keep temperatures within a proper range of 15 0C to 40 0C to

Get Started

Mechanical Design and Packaging of Battery

Feb 11, 2018 · Current Li-ion battery packs are prone to failure due to reasons such as continuous transmission of mechanical vibrations, exposure to

Get Started

Design approach for electric vehicle battery packs based on

Jan 30, 2024 · This work proposes a multi-domain modelling methodology to support the design of new battery packs for automotive applications. The methodology allows electro-thermal

Get Started

Optimization and Structural Analysis of

Nov 4, 2024 · Through weight reduction and structural optimization, an innovative power battery pack design scheme is proposed, aiming to achieve a more

Get Started

Design optimization of battery pack enclosure

Jan 24, 2018 · Lithium-ion Battery pack which is comprised of assembly of battery modules is the main source of power transmission for electric vehicles. During

Get Started

EV Battery Pack Design: Structure, Safety

Oct 4, 2024 · Discover how EV battery pack design shapes electric vehicle performance with a focus on structure, safety, thermal management, and

Get Started

Holistic Battery Pack Design

Jul 17, 2017 · The basic idea behind the presented battery principle, with regard to the mechanical design, is the use of the battery pack as a deformable member which can absorb deformation

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · This project offers a detailed overview of the process involved in designing a mechanical structure for an electric vehicle''s 18 kWh battery pack.

Get Started

Automotive Battery Pack Standards and Design

Apr 7, 2025 · The latest design of battery packs is converging towards a flat pack design located under passenger seats. The unit is connected to the vehicle chassis, and the mechanical

Get Started

Experimental and numerical studies on the

Lithium-ion battery can experience the risk of thermal runaway propagation due to various reasons. The emission of high-temperature vent gas from the cell during thermal runaway

Get Started

439747_1_En_8_Chapter 175..200

Feb 10, 2018 · Current Li-ion battery packs are prone to failure due to reasons such as continuous transmission of mechanical vibrations, exposure to high impact forces and, thermal runaway.

Get Started

Design and Analysis of Battery Thermal Management

Jan 18, 2023 · Proper Thermal Management can increase operational safety, efficiency, and overall battery life. Battery packs are to be used in electric airplane X-57 and other electric

Get Started

Mechanical-thermal coupling design on battery pack

To comprehensively investigate mechanical-thermal coupling properties and function-oriented design of battery pack, a novel battery pack with triangular micro-channel cold plate and the

Get Started

Mechanical Design of Battery Packs

This lesson covers the mechanical design of battery packs, starting with a review of the electrical design and the issues that can arise. The lesson also explains the calculation of capacity,

Get Started

Battery Pack Design: Maximizing Performance

5 days ago · Design Battery Pack: Engineers develop the physical layout and structure of the battery pack, considering factors such as cell arrangement,

Get Started

6 FAQs about [Battery pack mechanical structure thermal design]

How can mechanical design and battery packaging protect EV batteries?

Robust mechanical design and battery packaging can provide greater degree of protection against all of these. This chapter discusses design elements like thermal barrier and gas exhaust mechanism that can be integrated into battery packaging to mitigate the high safety risks associated with failure of an electric vehicle (EV) battery pack.

How does packaging design affect thermal performance of a battery pack?

Compactness of packaging design also has an appreciable impact on thermal performance of the battery pack. Research shows that increasing the cell-to-cell spacing for a battery pack from 1 to 10 mm can lead to a loss of approximately 1 °C in the steady-state cell core temperature, for all the three physical formats .

How mechanical design elements affect safety and reliability of EV battery packaging?

In this chapter, mechanical design elements affecting safety and reliability of EV battery packaging are discussed. Forces like mechanical vibration, impact energy and ambient temperature variations interact with the battery pack through different interfaces. These interactions need to be controlled for safe and reliable operation of battery pack.

Can a prismatic Lithium-ion battery pack be mechanically designed?

Development of a mechanical design of a prismatic lithium-ion battery pack for an electric vehicle. Journal of Power Sources, 274, 455-461. Zhang, Z., Zhang, F., & Bai, J. (2020). Multi-objective mechanical design optimization for prismatic lithium-ion battery pack structure. Applied Energy, 276, 115416.

How does a battery pack design work?

Extensive calculations are then carried out to determine the battery pack's energy, capacity, weight, and size. The design involves grouping cells into modules for easier management and protection, while also incorporating cell holders to enhance stability and minimize vibrations.

What is the pressure range for a battery pack?

The pressure range for a battery pack can range from 0.25 bar up to 5 bar, depending on the chemistry. The mechanical design of a battery pack needs to consider every element of the system, including static stiffness, dynamic stiffness, and behaviour of components.

Related Articles

-

Lithium-ion battery PACK product structure design

Lithium-ion battery PACK product structure design

-

UPS lithium battery pack internal structure

UPS lithium battery pack internal structure

-

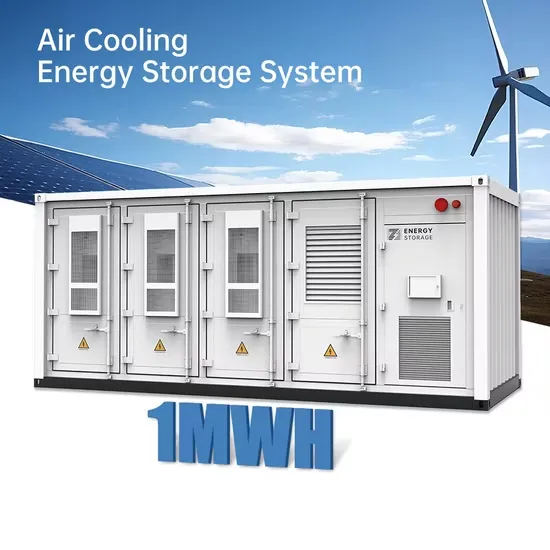

Battery pack air cooling design

Battery pack air cooling design

-

Battery pack factory in the Middle East

Battery pack factory in the Middle East

-

Lithium battery pack basics

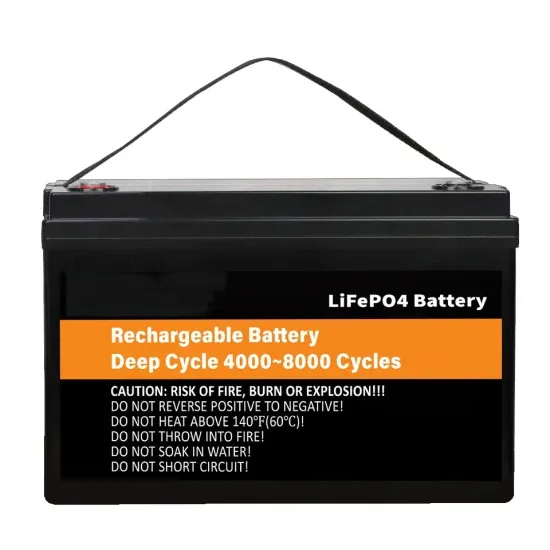

Lithium battery pack basics

-

Introduction to the design of energy storage battery container

Introduction to the design of energy storage battery container

-

Cabinet-type outdoor energy storage lithium battery pack

Cabinet-type outdoor energy storage lithium battery pack

-

How many mAh is the lithium battery pack

How many mAh is the lithium battery pack

-

North America Battery Pack Factory

North America Battery Pack Factory

-

How much does a lithium battery pack supplier cost in Johannesburg South Africa

How much does a lithium battery pack supplier cost in Johannesburg South Africa

Commercial & Industrial Solar Storage Market Growth

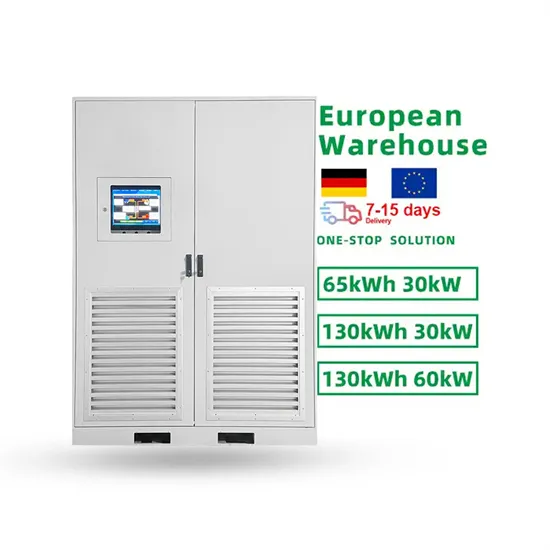

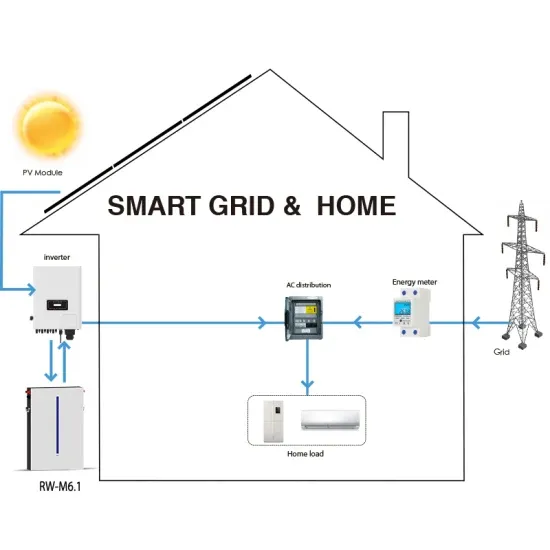

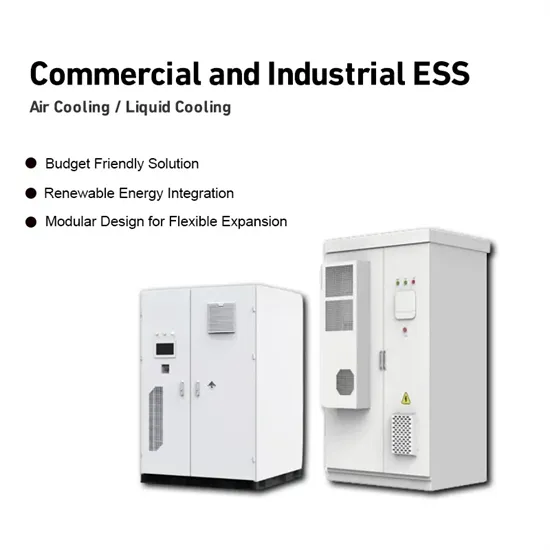

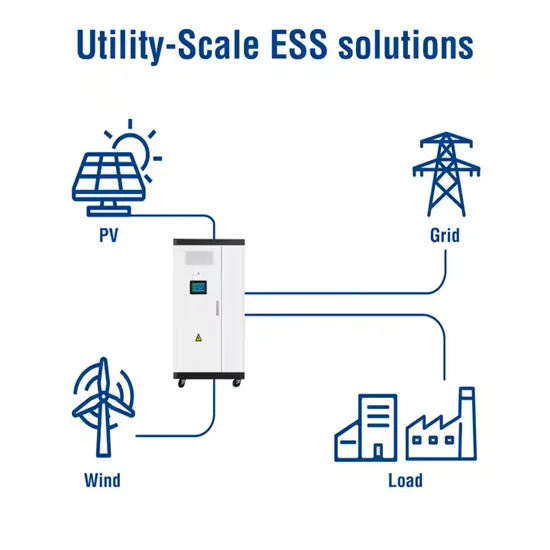

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.