Insulated Battery Box Guide for Lithium Battery

Apr 22, 2025 · Choosing the Best Insulated Battery Box for Lithium Batteries? Discover key factors such as size, material, and safety for optimal protection

Get Started

How to design battery packs, tutorial for Design Engineers

April 21, 2023 Engineering Guidelines for Designing Battery Packs Custom design and manufacture of state-of-the-art battery chargers, battery packs, UPS, and power supplies

Get Started

Lithium Ion Battery Packaging: Soft Pack Design

Apr 8, 2025 · Soft-pack lithium-ion battery packaging encloses battery cells in a flexible, laminated aluminum-plastic film instead of traditional hard casing. This

Get Started

Mechanical Design and Packaging of Battery

Feb 11, 2018 · In this work, the integration of Lithium-ion battery into an EV battery pack is investigated from different aspects, namely different battery

Get Started

Compact Battery Cases, Plastic Battery boxes,

Compact Battery Cases, Plastic Battery boxes, SLA Battery Housing for Lithium-ion battery E&J Technology Group Co., Ltd is with in-house tooling plant,

Get Started

Design for Assembly and Disassembly of Battery Packs

Aug 23, 2019 · Based on the evaluation, an "ideal" battery is developed with focus on the hardware, hence the housing, attachment of modules and wires, thermal system and battery

Get Started

Design and Analysis of Large Lithium-Ion Battery Systems

May 4, 2021 · This new resource provides you with an introduction to battery design and test considerations for large-scale automotive, aerospace, and grid applications. It details the

Get Started

Mechanical Design and Packaging of Battery

Feb 11, 2018 · Safety and reliability are the two key challenges for large-scale electrification of road transport sector. Current Li-ion battery packs are prone

Get Started

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Nowadays, battery design must be considered a multi-disciplinary activity focused on product sustainability in terms of environmental impacts and cost. The paper reviews the

Get Started

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · At Bonnen Battery, our engineering team follows a systematic approach to battery pack design, ensuring optimal performance and safety for

Get Started

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · More than 8 years ago I began an effort to write a book as an introduction to the lithium (Li)-ion battery and electric vehicle (EV) industry. The book did a great job of doing just

Get Started

Custom Battery Pack Manufacturing & Energy

48V Solar Battery 72V Golf Cart Battery Precision-Crafted Lithium Ion Battery Solutions As a certified OEM/ODM lithium battery pack specialist since 2007,

Get Started

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get Started

19 DIY Battery Box Projects

Apr 23, 2022 · Create a DIY 80AH lithium iron phosphate battery box and store energy from wind, solar, and even manually as backup power. Lithium iron

Get Started

How to Select the Best Lithium Battery Box for Your Devices?

Dec 23, 2024 · A lithium battery box offers reliable, efficient power for outdoor activities, RVs, and solar systems. Learn how to choose the right one for your needs.

Get Started

Battery Box at Best Price in India

Find here online price details of companies selling Battery Box. Get info of suppliers, manufacturers, exporters, traders of Battery Box for buying in India.

Get Started

Benchmarking Battery Packs

Aug 13, 2025 · The battery pack database is now available as an excel file via a download. This is $15 and gives high level data for a number of battery packs

Get Started

The Ultimate Guide to 18650 Battery Packs:

Apr 18, 2025 · The 18650 battery pack is a modular energy storage system built from 18650 cylindrical lithium-ion cells, each measuring 18mm in diameter and

Get Started

Build Your Own DIY Battery Box for LiFePO4 Batteries

Dec 25, 2023 · Learn how to build a DIY battery box for LiFePO4 batteries, ensuring optimal performance and safety. Choose the right enclosure, design the layout, implement proper

Get Started

Lithium battery storage box – LithiumSafe

3 days ago · The LithiumSafe™ Battery Box is designed for safely storing, charging and transporting lithium ion batteries. The most intensively tested

Get Started

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

Get Started

How to design a battery pack?

In the battery pack design process. You''ll explore the different factors that need to be considered, from the type of battery cells to the size and shape of the pack.

Get Started

Comparison of Different Packaging Methods for Lithium-ion Batteries

Lithium-ion batteries are divided into two categories, hard casesoft pack, according to the different s of the cells. The materials of the hard are mainly steel aluminum s, while the soft pack uses

Get Started

Introduction to battery pack design and

Most garage-builders who decide to assemble their own battery pack usually have a lot of experience. However, pack-building continues to be a frequent

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · This project offers a detailed overview of the process involved in designing a mechanical structure for an electric vehicle''s 18 kWh battery pack.

Get Started

Battery Pack Simulation Models

3 days ago · Create battery pack models in minutes - all cell types, including cooling, customizable. The Batemo Pack Designer is the solution!

Get Started

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack. Before diving into the design process, it''s crucial to

Get Started

Step By Step Design Guide Packaging For Custom Batteries

Mar 10, 2025 · Whether you''re packaging lithium-ion cells, rechargeable batteries, or specialized power solutions, custom battery packaging serves as your first line of defense and a powerful

Get Started

Lithium Battery Pack Designer

The app may then be used to compute a battery pack temperature profile based on the thermal mass and generated heat associated with the voltage losses of

Get Started

Battery Pack Thermal Design

Aug 17, 2016 · Battery Pack Thermal Design Ahmad Pesaran National Renewable Energy Laboratory Golden, Colorado NREL/PR-5400-66960 NREL is a national laboratory of the U.S.

Get Started

6 FAQs about [Lithium battery box pack design]

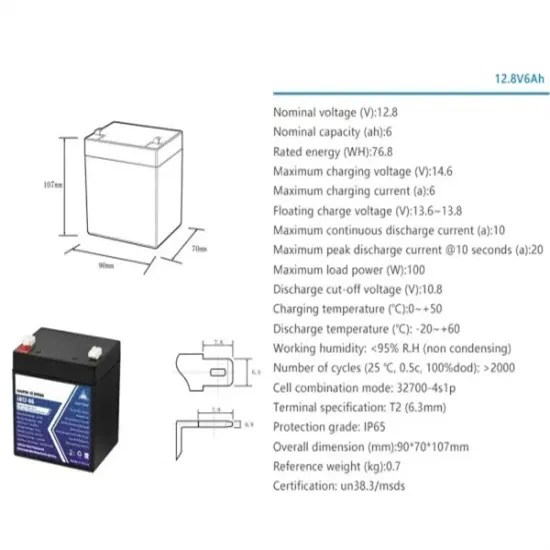

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

How do you design a custom lithium battery pack?

This blog post outlines the comprehensive design process we follow when developing custom lithium battery packs for our clients. The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process.

Is there a standard size lithium-ion battery pack?

Perhaps the first and most important statement we can make about battery packaging is this: there is no standard size lithium-ion battery pack and there is not likely to be one in the near future.

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

Related Articles

-

Lithium battery pack design price

Lithium battery pack design price

-

Creo design lithium battery pack

Creo design lithium battery pack

-

60v lithium iron phosphate battery pack

60v lithium iron phosphate battery pack

-

Lithium battery pack solution

Lithium battery pack solution

-

Which Paraguayan lithium iron phosphate battery pack decays faster

Which Paraguayan lithium iron phosphate battery pack decays faster

-

Does it need to balance the voltage when making a lithium battery pack

Does it need to balance the voltage when making a lithium battery pack

-

Standard voltage of lithium battery pack

Standard voltage of lithium battery pack

-

Hungarian large capacity lithium battery pack

Hungarian large capacity lithium battery pack

-

El Salvador low rate lithium battery pack

El Salvador low rate lithium battery pack

-

UPS lithium battery pack internal structure

UPS lithium battery pack internal structure

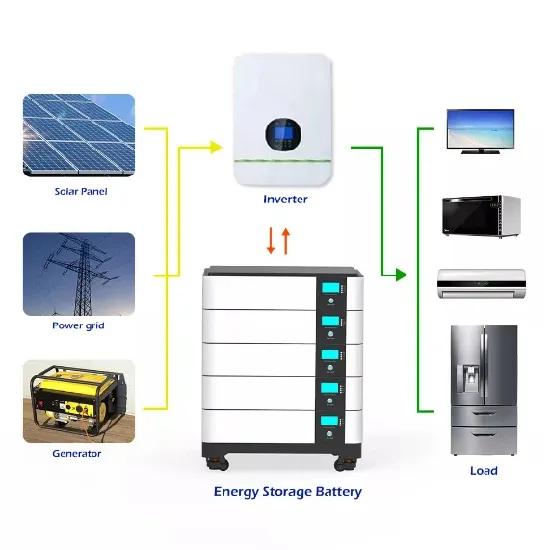

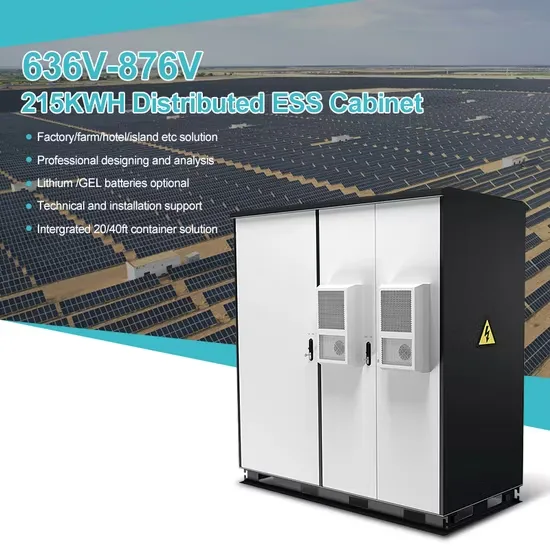

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.