Lithium-ion Battery: Structure, Working Principle

Mar 21, 2022 · Ⅰ. What is a lithium-ion battery? Lithium batteries are divided into lithium batteries and lithium-ion batteries. Both mobile phones and laptops use

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · This project offers a detailed overview of the process involved in designing a mechanical structure for an electric vehicle''s 18 kWh battery pack.

Get Started

Handbook On Lithium Battery Pack Design

Oct 30, 2023 · The second type of rechargeable lithium battery is called a lithium ion battery, which has a negative terminal that consists of a carbon-based material, usually graphite, or

Get Started

FEATURE: Battery Design – the shape of things

Feb 3, 2025 · By optimizing the architecture of the battery electrodes, Addionics claims it can enhance the performance of various battery chemistries,

Get Started

Battery Pack Design: Efficient & Safe Energy

Mar 15, 2025 · Learn how to design a high-performance battery pack with the right cell configuration, cooling system, and safety features.

Get Started

Deep Dive into brand new Design and

The evolution of lithium-ion battery technology has revolutionized the energy storage landscape. As the demand for efficient and sustainable energy

Get Started

Battery Pack Design: Maximizing Performance

5 days ago · As the heartbeat of electric vehicles and modern energy storage, battery packs are more than just cells; they''re a symphony of components,

Get Started

DOE ESHB Chapter 3: Lithium-Ion Batteries

Mar 17, 2021 · Li-ion batteries currently dominate the grid-scale battery market due to their extensive history in consumer products and growing production volumes for electric vehicles.

Get Started

The Handbook of Lithium-Ion

Aug 16, 2025 · In a Chapter I wrote for the Handbook of Lithium-ion Battery Applications(Warner, 2014), I offered a brief look at Li-ion battery design considerations and discussed cells,

Get Started

Understanding Lithium Battery Pack Enclosure

May 7, 2025 · Understanding Lithium Battery Pack Enclosure Design for Electric Vehicles and Boats At Bonnen Battery, we specialise in crafting high

Get Started

Factors Influencing the Design of Custom

Apr 30, 2024 · A lithium-ion battery pack''s fundamental structure consists of many key components that work together to store and transfer electrical energy

Get Started

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · More than 8 years ago I began an effort to write a book as an introduction to the lithium (Li)-ion battery and electric vehicle (EV) industry. The book did a great job of doing just

Get Started

Introduction to lithium-ion rechargeable battery

Feb 28, 2017 · Lithium-ion chemistry is not inherently safe so cell selection, manufacturing process, electrical and mechanical design of the battery

Get Started

A cell level design and analysis of lithium-ion battery packs

Oct 31, 2024 · The world is gradually adopting electric vehicles (EVs) instead of internal combustion (IC) engine vehicles that raise the scope of battery design, battery pack

Get Started

Lithium battery module design production

Aug 18, 2025 · Introduction of lithium battery module Lithium battery module can be understood as a lithium-ion battery cell combined in series and parallel,

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · PDF | This project offers a detailed overview of the process involved in designing a mechanical structure for an electric vehicle''s 18 kWh

Get Started

Design approach for electric vehicle battery packs based on

Jan 30, 2024 · This work proposes a multi-domain modelling methodology to support the design of new battery packs for automotive applications. The methodology allows electro-thermal

Get Started

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack. Before diving into the design process, it''s crucial to

Get Started

Mechanical Design and Packaging of Battery

Feb 11, 2018 · Current Li-ion battery packs are prone to failure due to reasons such as continuous transmission of mechanical vibrations, exposure to

Get Started

Lithium Ion Battery Packaging: Soft Pack Design

Apr 8, 2025 · Soft-pack lithium-ion battery packaging faces key design challenges. Learn how manufacturers solve issues for safety and performance.

Get Started

Key Points of Lithium Battery PACK

Jun 27, 2024 · Conclusion The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a

Get Started

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · Abstract With increasing research on lithium batteries, the technology of electric vehicles equipped with lithium battery packs as the main energy storage system has become

Get Started

The Ultimate Guide to 18650 Battery Packs:

Apr 18, 2025 · The 18650 battery pack is a modular energy storage system built from 18650 cylindrical lithium-ion cells, each measuring 18mm in diameter and

Get Started

EV Battery Pack Designs: An Overview

Apr 25, 2022 · A well-designed battery pack needs to compete with petrol-based engines when it comes to performance. That''s a real challenge because

Get Started

EV Battery Pack Design: Structure, Safety

Oct 4, 2024 · Discover how EV battery pack design shapes electric vehicle performance with a focus on structure, safety, thermal management, and

Get Started

Multiphysics simulation optimization framework for lithium-ion battery

Jan 15, 2022 · This study presents a dual-stage multiphysics simulation optimization methodology for comprehensive concept design of Lithium-ion (Li-ion) battery packs for EV applications.

Get Started

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · All essential components of a lithium ion battery pack are addressed to support engineers developing both simple portable devices and complex motive applications. The

Get Started

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · the design theory and some patents demonstration of some key points on the robustness of the structural design of the battery pack. US Patent No. 8663824 discloses a

Get Started

6 FAQs about [Lithium-ion battery PACK product structure design]

What is the architecture of a lithium-ion battery pack?

Conclusion The architecture of a lithium-ion battery pack is a complex interplay of various design considerations. From energy storage and voltage range to cell configuration and mechanical construction, each aspect plays a pivotal role in determining the pack’s performance and utility.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What are lithium ion batteries made of?

In lithium-ion batteries, the substrate is often a very thin film of aluminum. The anode is the “negative” half of the battery cell and is usually made up of a thin copper substrate that is coated with the active anode material.

What are the components of a battery pack?

Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP). Modules: Groups of cells assembled together in a specific configuration (series, parallel, or a combination) to achieve the desired voltage and capacity.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What is the echanical structure of a battery pack?

echanical structure, the basic structure of a battery pack is determined by the desired performance as well as cell characteristics. In this research, the Samsung 35E 18650 cylindrical cells are chosen. 20 battery c

Related Articles

-

Battery pack mechanical structure thermal design

Battery pack mechanical structure thermal design

-

Battery pack bms design

Battery pack bms design

-

Lithium battery pack design price

Lithium battery pack design price

-

Creo design lithium battery pack

Creo design lithium battery pack

-

Lithium battery pack product model

Lithium battery pack product model

-

Lithium battery box pack design

Lithium battery box pack design

-

Hungarian large capacity lithium battery pack

Hungarian large capacity lithium battery pack

-

6 2 Ah lithium battery pack

6 2 Ah lithium battery pack

-

Lithium battery pack factory voltage

Lithium battery pack factory voltage

-

Assemble 32650 lithium battery pack

Assemble 32650 lithium battery pack

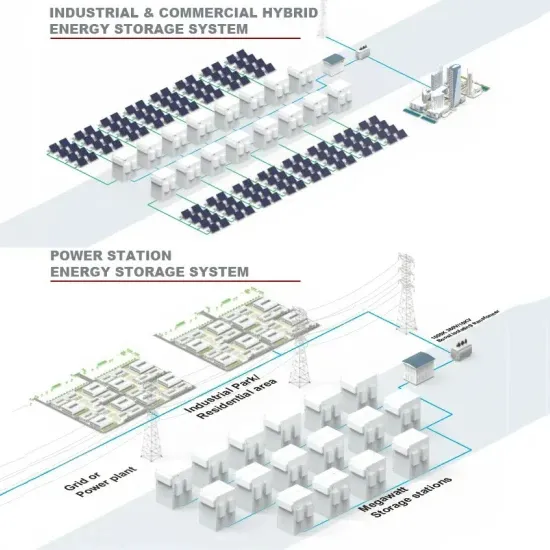

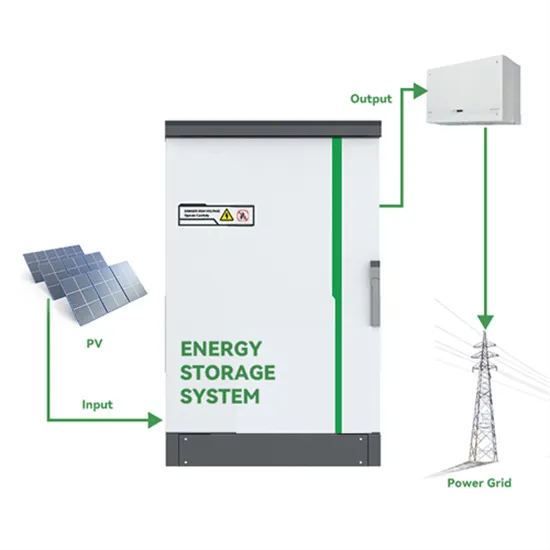

Commercial & Industrial Solar Storage Market Growth

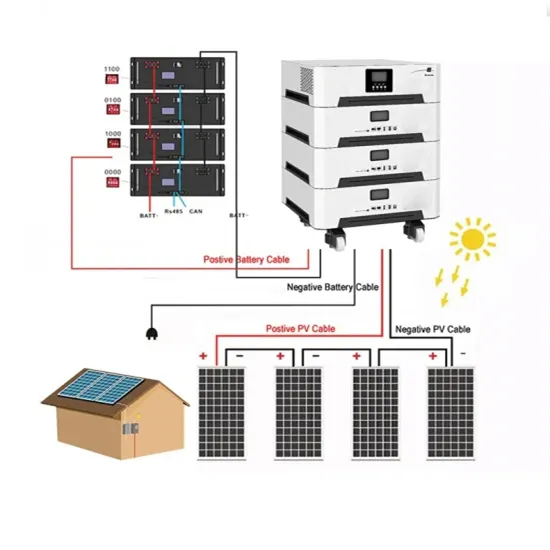

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.